Low temperature X ray induced thermoluminescence spectrum measuring device

A measurement device, thermoluminescence technology, applied in the direction of measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of affecting the content of analysis information, poor spectral repeatability, detection, etc., to achieve good spectral repeatability, The effect of enriching data information and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

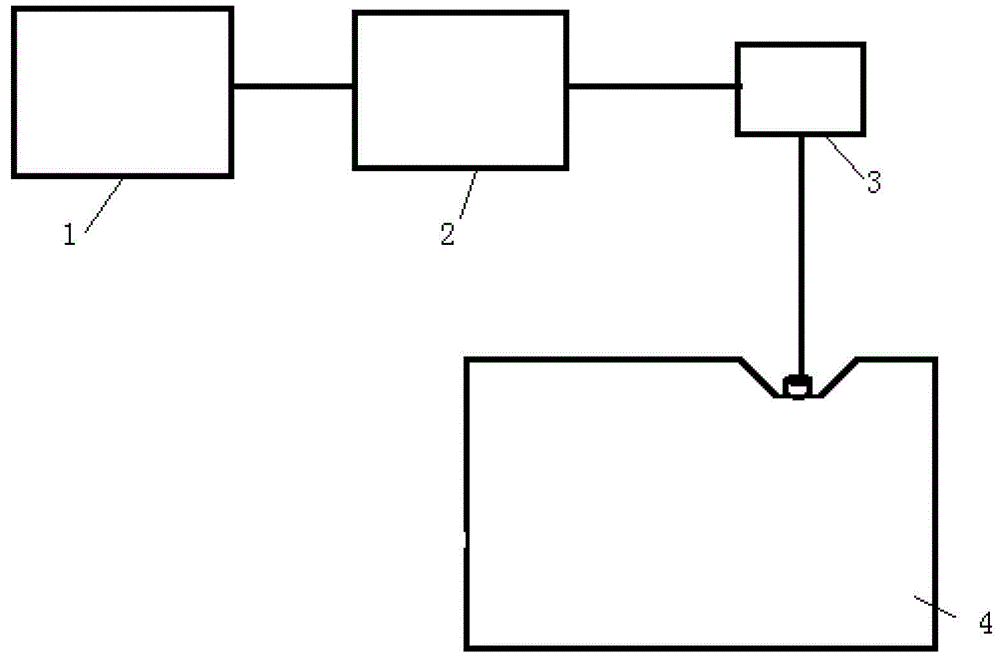

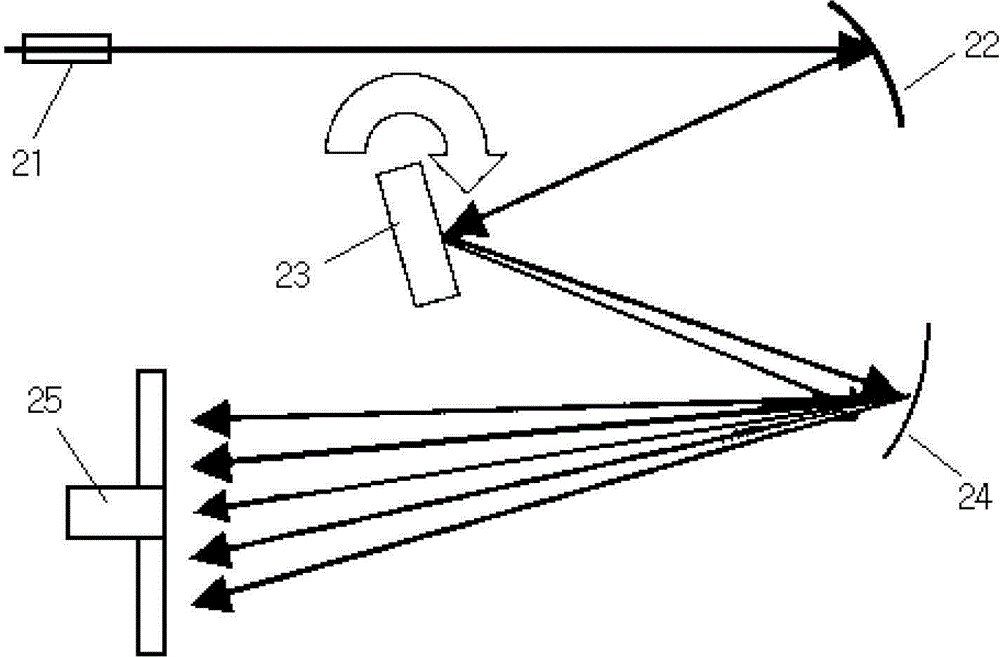

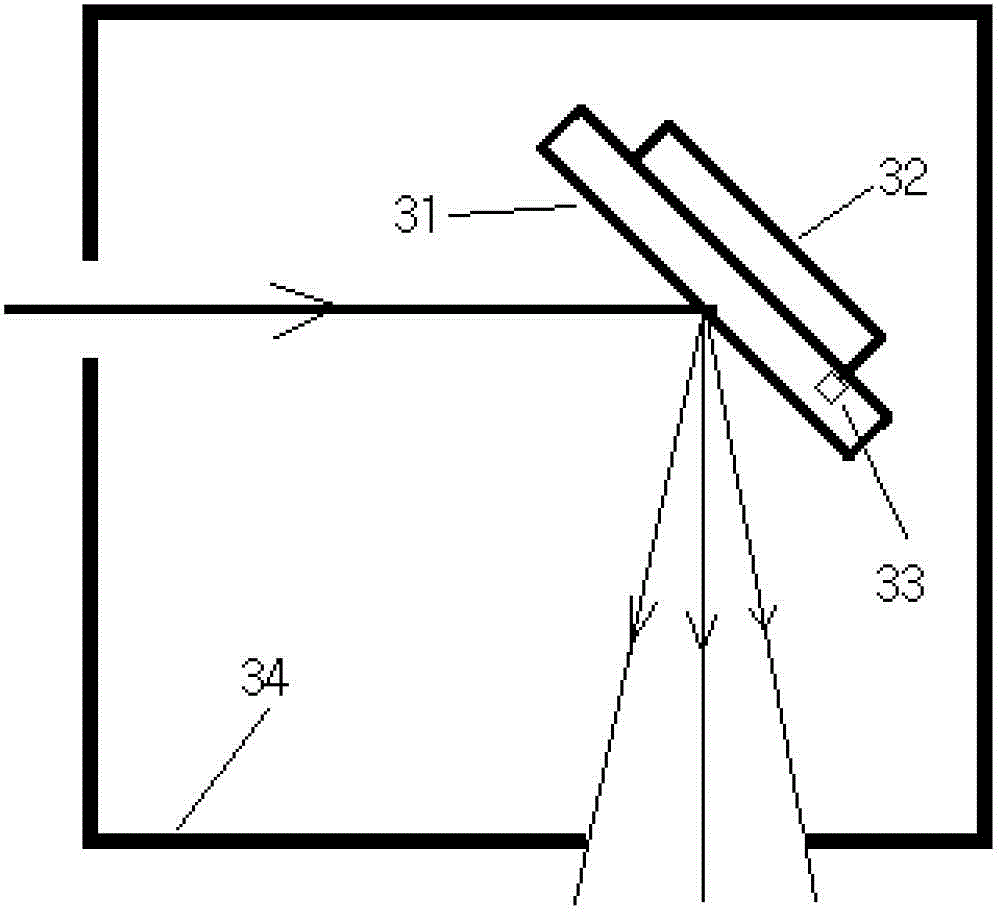

[0072] Figure 6 It is the schematic diagram of the X-Ray induced low-temperature thermoluminescence test system, in which the maximum voltage of the X-Ray light source is 90Kv, and the current is 2-2.5mA; the temperature range of the sample chamber is 77K (liquid nitrogen temperature)-500K, and the heating rate is <6K / min (adjustable); the detection sensitivity of the spectrometer is 26 photons (@250nm). The main indicators of the final test system are shown in the table below:

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com