Patch-type power device integration scheme applied to electric control product of electric vehicle

A technology for power devices and electric vehicles, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve problems such as high thermal resistance of metal substrates, complex processes, and impact on capacitor life, so as to improve peak impact capability and save complex Connecting and improving the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

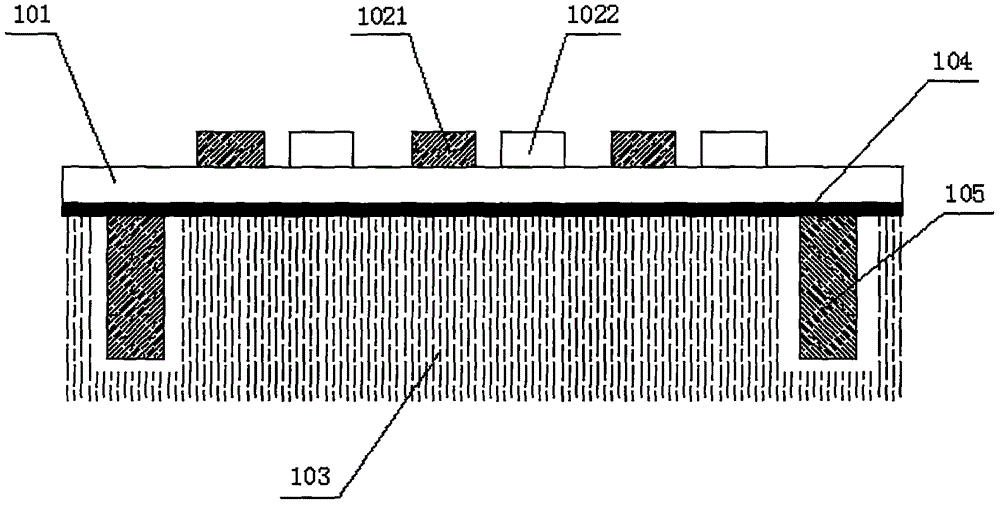

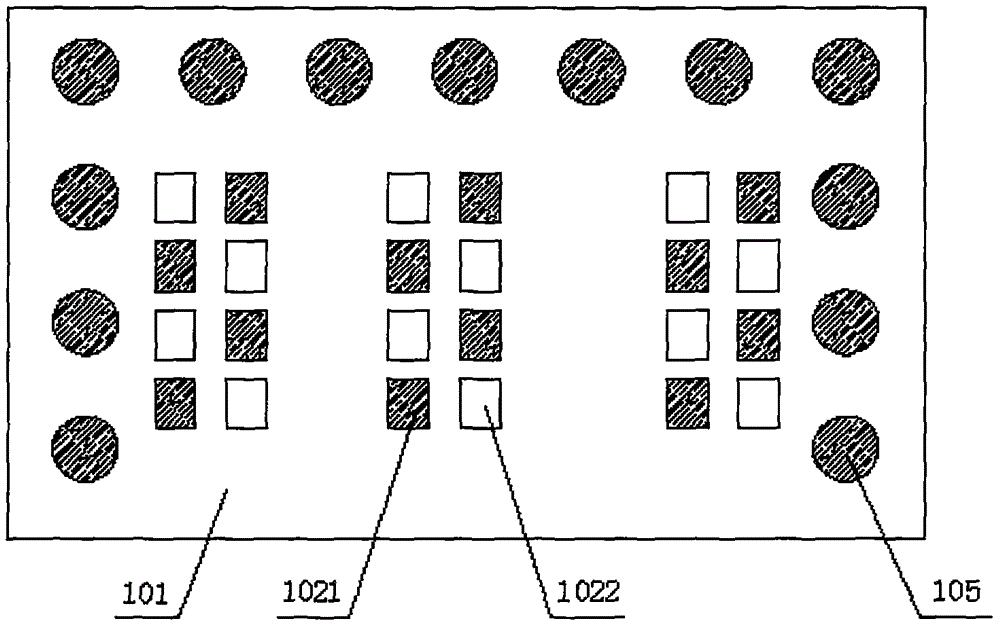

[0014] A patch-type power device integration scheme applied to electric vehicle electronic control products, such as figure 1 , figure 2 As shown, a thick copper PCB 101 embedded or buried with multiple copper blocks is used as the main circuit carrier, the SMD power device is welded on the copper block, and the bus capacitor 105 is welded on the thick copper PCB 101. The thick copper PCB 101 is crimped onto the heat dissipation cold plate 103 , and an insulating heat conduction gasket 104 is provided between the thick copper PCB 101 and the heat dissipation cold plate 103 .

[0015] SMD power devices are welded on the copper block, using the high thermal conductivity of copper to transmit heat. At the same time, the heat capacity of the thick copper block can effectively improve the peak impact capability; there is an insulation and heat conduction between the thick copper PCB and the heat dissipation cold plate The gasket realizes the extremely low conduction thermal resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com