Five-junction solar cell based on inp substrate and preparation method thereof

A solar cell and substrate technology, applied in the field of solar photovoltaics, can solve the problems that affect the performance of the fourth sub-cell of InGaP, the overall performance of the four-junction cell, the inability to achieve current matching, and reduce the performance of the cell, so as to improve the conversion efficiency of the cell and divide it meticulously , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

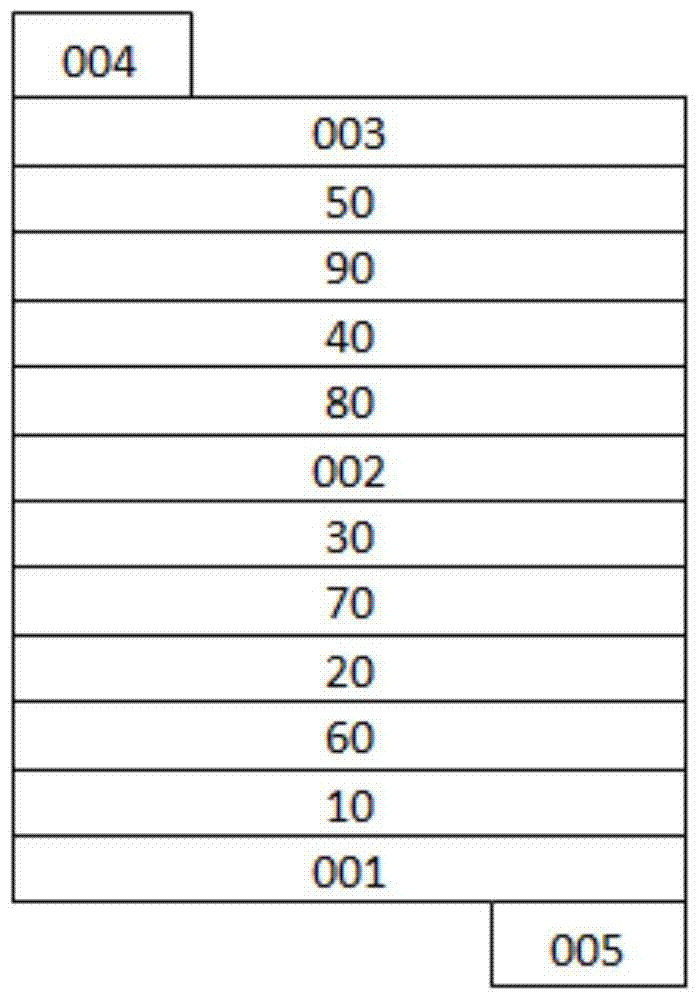

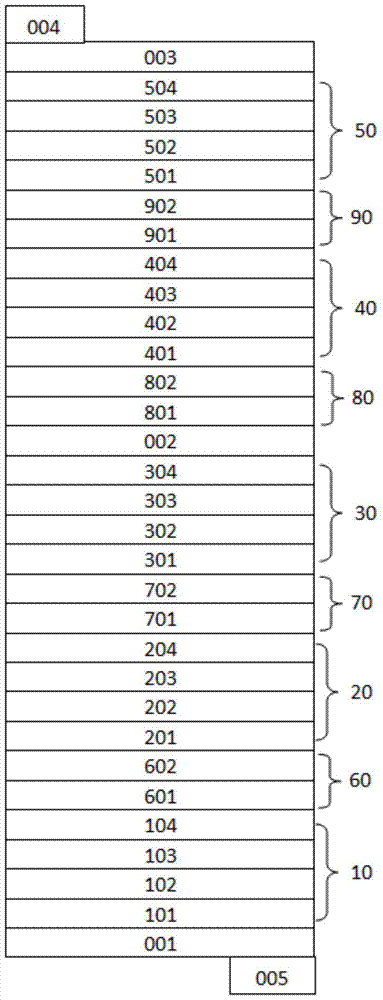

[0049] Use MOCVD (Metal Organic Chemical Vapor Deposition) as the growth process to provide p-type InP substrate 001, and the growth source is TMGa, TMAl, TMIn, AsH 3 and PH 3 , the dopant source n-type is Si 2 h 6 , p-type is DEZn and CBr 4 . The growth temperature is about 650°C, and the reaction chamber pressure is 100 Torr. After high temperature treatment to remove impurities on the surface of the substrate, according to image 3 The five-junction solar cell structure shown grows each layer structure sequentially.

[0050] (1), InGaAsP first subcell 10: p-type InP (1×10) doped with Zn comprising 0.2 microns thick 18 cm -3 ) the first back field layer 101, 2.5 micron thick p-type InGaAsP doped with Zn (2×10 17 cm -3 ) n-type InGaAsP doped with Si (2×10 18 cm -3 ) the first emitter region 103 and 0.05 micron thick n-type InAlGaAs doped with Si (5×10 18 cm -3 ) first window layer 104. Wherein, the p-type InGaAsP first base region 102 and the n-type InGaAsP firs...

Embodiment 2

[0064] Use MOCVD as the growth method, provide p-type InP substrate 001, and the growth source is TMGa, TMAl, TMIn, AsH 3 and PH 3 , the dopant source n-type is Si 2 h 6 and DETe, p-type is DEZn and CBr 4 . The growth temperature is about 650°C, and the reaction chamber pressure is 100 Torr. After high temperature treatment to remove impurities on the surface of the substrate, according to image 3 The five-junction solar cell structure shown grows each layer structure sequentially.

[0065] (1), InGaAsP first subcell 10: p-type InP (1×10) doped with Zn comprising 0.2 microns thick 18 cm -3 ) the first back field layer 101, 2.5 micron thick p-type InGaAsP doped with Zn (2×10 17 cm -3 ) n-type InGaAsP doped with Si (2×10 18 cm -3 ) first emitter region 103 and 0.05 micron thick n-type InP doped with Si (5×10 18 cm -3 ) first window layer 104. Wherein, the p-type InGaAsP first base region 102 and the n-type InGaAsP first emitter region 103 are lattice-matched with ...

Embodiment 3

[0079] Using MBE (molecular beam epitaxy) as the growth process, a p-type InP substrate 001 is provided, the growth source is solid single source Ga, Al, In, As and P, the n-type dopant source is Si, and the p-type is Be and C. The growth temperature is about 500°C. After the substrate is degassed and impurity removed, according to the following image 3 The five-junction solar cell structure shown grows each layer structure sequentially.

[0080] (1), InGaAsP first subcell 10: p-type InP (1×10 18 cm -3 ) the first back field layer 101, 2.5 micron thick p-type InGaAsP (2×10 17 cm -3 ) n-type InGaAsP doped with Si (2×10 18 cm -3 ) the first emitter region 103 and 0.05 micron thick n-type InAlGaAs doped with Si (5×10 18 cm -3 ) first window layer 104. Wherein, the p-type InGaAsP first base region 102 and the n-type InGaAsP first emitter region 103 are lattice-matched with the InP substrate 001, the bandwidth is 0.78eV, and the corresponding P composition is 8%.

[0081...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com