Lithium sulfide/carbon composite nanometer material and preparation method and application thereof

A nanomaterial, lithium sulfide technology, applied in the field of material science, can solve the problems of difficulty in realizing lithium sulfide/carbon nanocomposite materials, harsh operating conditions, low process cost, etc., and achieves controllable morphology, high controllability, and raw materials. Inexpensive and accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

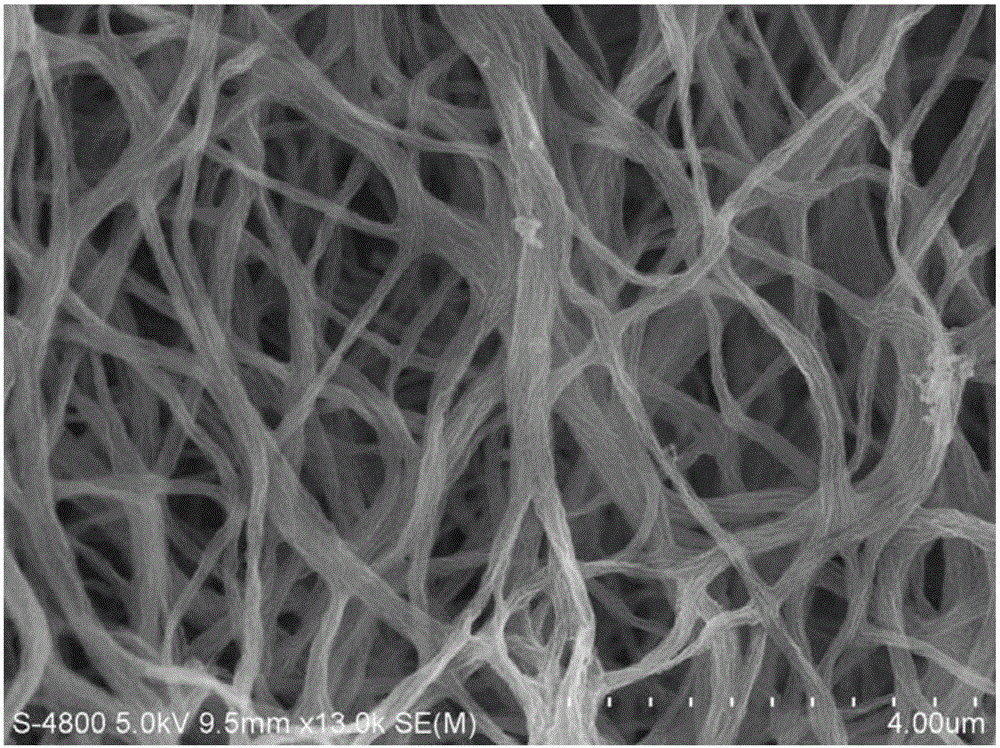

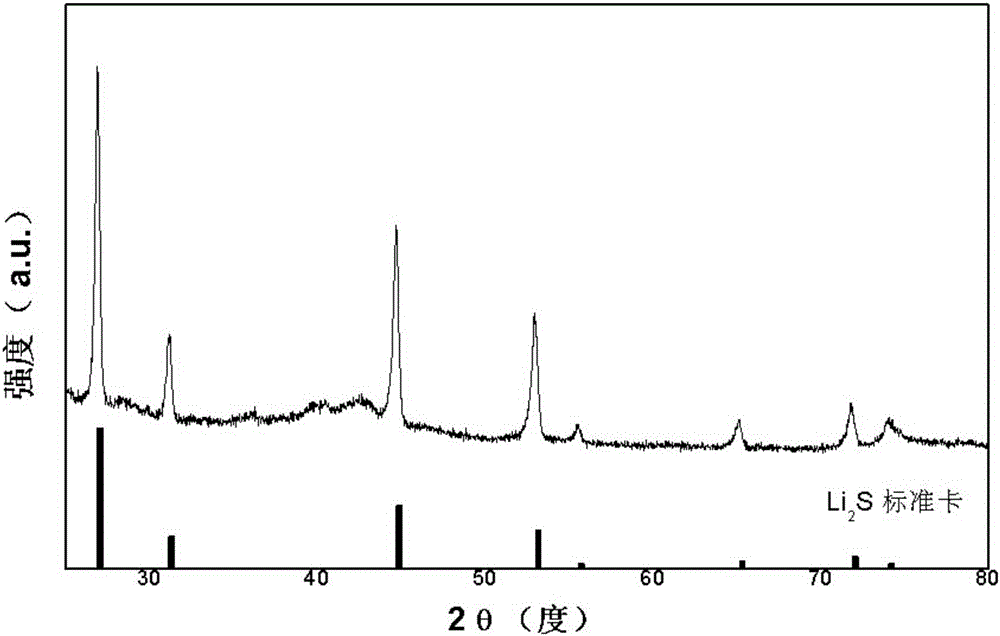

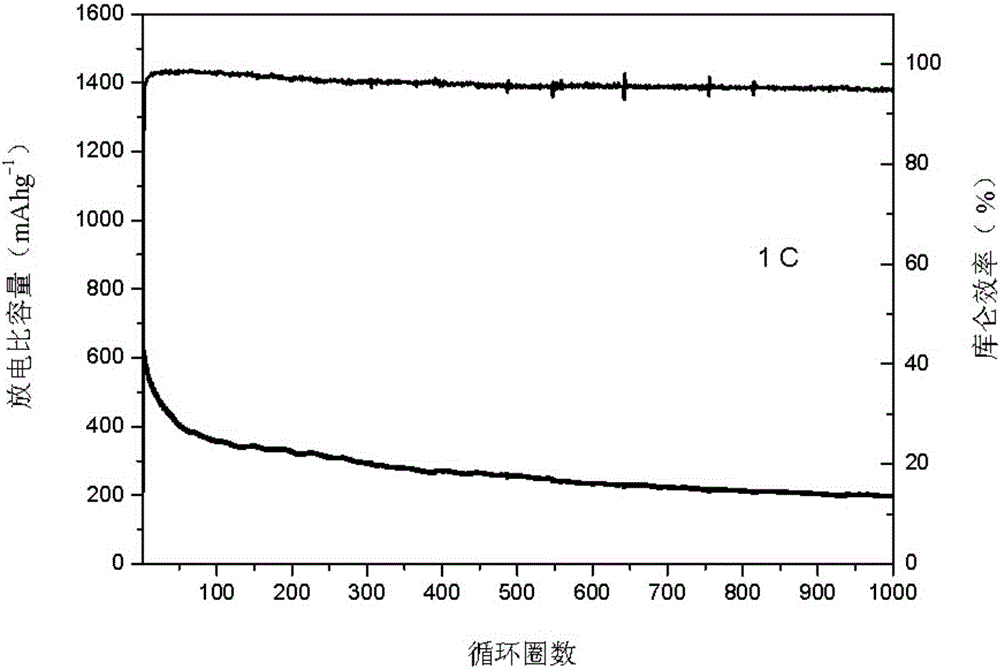

Embodiment 1

[0035] Embodiment 1: Li 2 SO 4 ·H 2O (20wt%, accounted for mass fraction in the final spinning solution, the same below) was dissolved in the mixed solvent of DMF (0wt%) and deionized water (60wt%), added PVP (Mw=1300000, 20wt%) ), stirring under magnetic stirring (100rpm) for 24h to form a uniform and transparent solution (ie spinning solution). Add the prepared spinning solution into the liquid storage tube of the spinning device for electrospinning, the nozzle diameter is 0.5mm, the angle between the nozzle and the horizontal plane is adjusted to 70°, a DC voltage of 13kV is applied, the curing distance is 15cm, and the temperature is 25 °C and a relative humidity of 30%, Li 2 SO 4 / PVP composite nanofibers. the Li 2 SO 4 / PVP composite nanofibers were placed in a program-controlled temperature box furnace for heat treatment, the heating rate was 2°C / min, and the temperature was kept at 350°C for 4 hours in an air atmosphere, and then naturally cooled to room tempera...

Embodiment 2

[0036] Embodiment 2: Li 2 SO 4 ·H 2 O (10wt%, accounted for mass fraction in the final spinning solution, the same below) was dissolved in the mixed solvent of DMF (30wt%) and deionized water (50wt%), added PVP (Mw=1300000, 10wt% ), stirring under magnetic stirring (2000rpm) for 4h to form a uniform and transparent solution (ie spinning solution). Add the prepared spinning solution into the liquid storage tube of the spinning device for electrospinning, the nozzle diameter is 0.3mm, the angle between the nozzle and the horizontal plane is adjusted to 10°, a DC voltage of 7kV is applied, the curing distance is 40cm, and the temperature is 35 °C, 10% relative humidity, Li 2 SO 4 / PVP composite nanofibers. the Li 2 SO 4 / PVP composite nanofibers were placed in a program-controlled temperature box furnace for heat treatment, the heating rate was 5°C / min, and the temperature was kept at 350°C for 4 hours in an air atmosphere, and then naturally cooled to room temperature wit...

Embodiment 3

[0037] Embodiment 3: with Li 2 SO 4 ·H 2 O (5wt%, the mass fraction in the final spinning solution, the same below) was dissolved in a mixed solvent of DMF (20wt%) and deionized water (45wt%), and PVP (Mw=1300000, 30wt%) was added ), stirring under magnetic stirring (500rpm) for 24h to form a uniform and transparent solution (i.e. spinning solution), adding the prepared spinning solution to the liquid storage tube of the spinning device for electrostatic spinning, the nozzle diameter is 0.9mm, Adjust the angle between the nozzle and the horizontal plane to be 20°, apply a DC voltage of 20kV, cure at a distance of 20cm, temperature at 0°C, and relative humidity of 60%, to obtain Li 2 SO 4 / PVP composite nanofibers. the Li 2 SO 4 / PVP composite nanofibers were heat treated in a programmed temperature-controlled box furnace with a heating rate of 10°C / min, kept at a constant temperature of 350°C for 4 hours in an air atmosphere, and then naturally cooled to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com