Preparation method for cathode paste of high-capacity lithium ion battery

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of difficult dispersion of mixed conductive agents, achieve low internal resistance, ensure consistency, and reduce agglomeration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

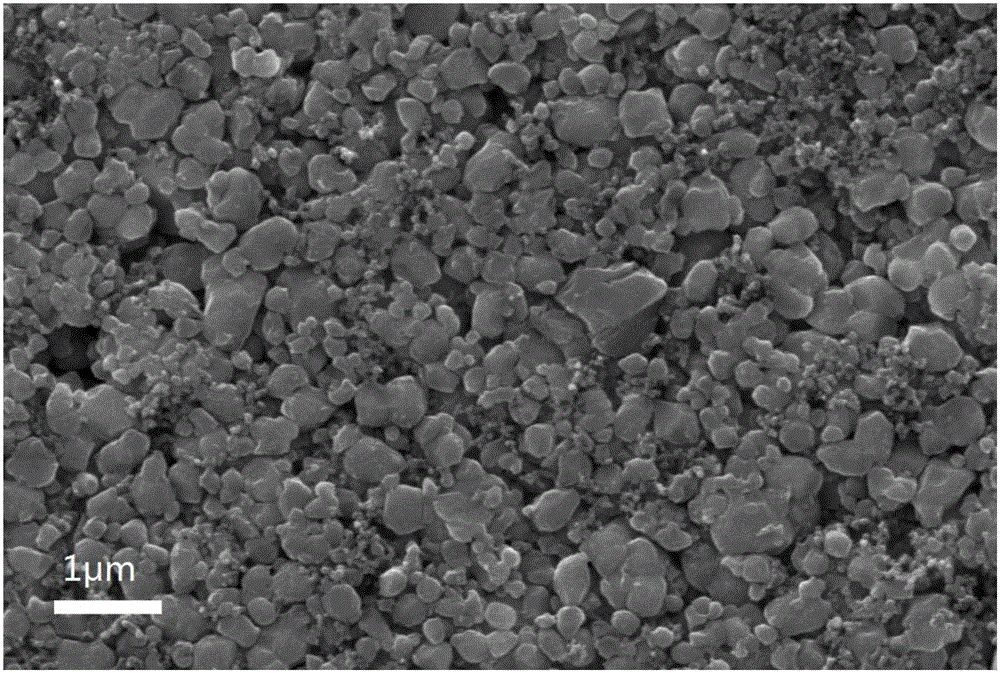

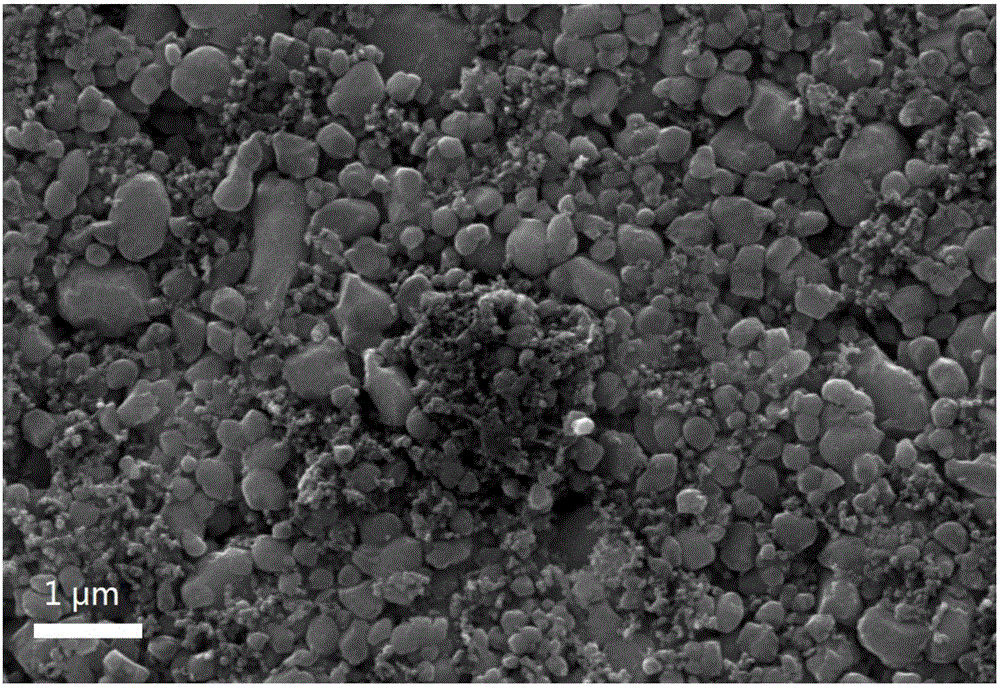

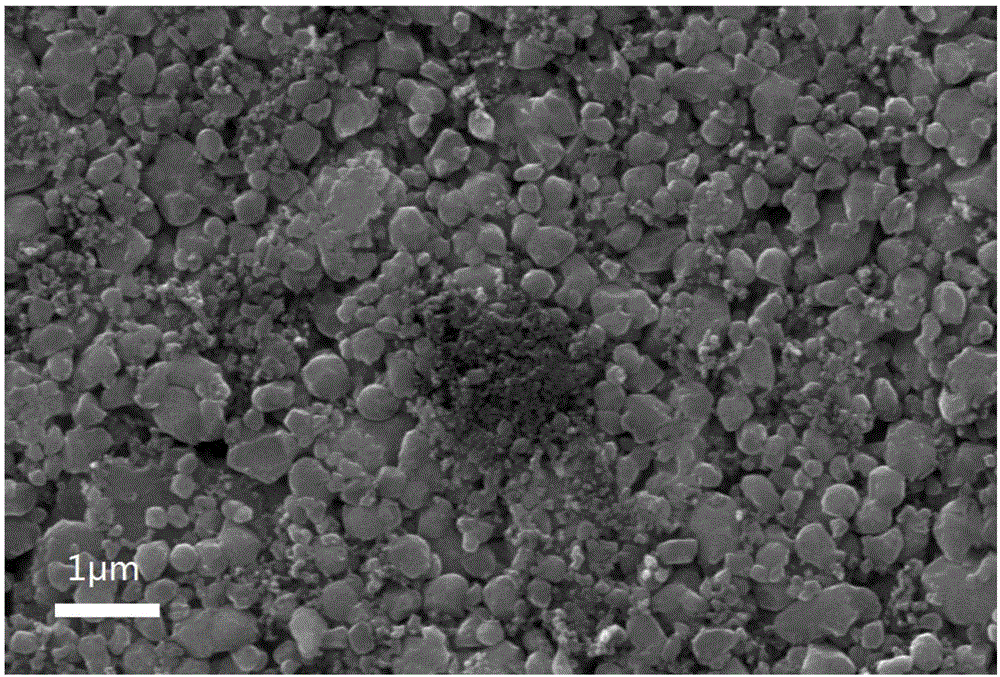

Image

Examples

Embodiment 1

[0028] The preparation method of the positive electrode slurry of the large-capacity lithium-ion battery in this embodiment, each component is based on lithium iron phosphate: polyvinylidene fluoride: Super-p: KS-6: N-methylpyrrolidone = 93:3.5:2:1.5: The mass ratio of 72.4 is weighed, and the preparation steps are as follows. The mixing equipment in the following steps is a double planetary vacuum mixer. The control method of the slurry temperature is to pass into the constant temperature circulating water on the wall of the mixing tank:

[0029] 1) Before preparing the slurry, first bake lithium iron phosphate, conductive agent Super-p and KS-6 at 115°C for 3 hours under vacuum conditions, bake polyvinylidene fluoride at 85°C for 5 hours under vacuum conditions, and then The temperature is -0.08MPa. After the baking is finished, the temperature is naturally lowered to below 40°C and set aside;

[0030] 2) Dissolve polyvinylidene fluoride in N-methylpyrrolidone equivalent to ...

Embodiment 2

[0038] The preparation method of the positive electrode slurry of the large-capacity lithium-ion battery in this embodiment, each component according to lithium iron phosphate: polyvinylidene fluoride: Super-p: KS-6: N-methylpyrrolidone = 92:4:2.5:1.5: The mass ratio of 69.5 is taken by weighing, and the preparation steps are as follows:

[0039] 1) Before preparing the slurry, first bake lithium iron phosphate, conductive agent Super-p and KS-6 at 120°C for 3.3h under vacuum conditions, and bake polyvinylidene fluoride at 81°C for 5.8h under vacuum conditions , the vacuum degree is -0.083MPa, after the baking is completed, the temperature is naturally lowered to below 40°C, and it is set aside;

[0040] 2) Dissolve polyvinylidene fluoride in N-methylpyrrolidone equivalent to 16 times its own weight, stir and disperse in the glue machine under vacuum for 1.5h, the vacuum degree is -0.083MPa, the stirring revolution speed is 22rpm, disperse The speed is 1100rpm. During the pre...

Embodiment 3

[0048] The preparation method of the positive electrode slurry of the large-capacity lithium-ion battery in this embodiment, each component is based on lithium iron phosphate: polyvinylidene fluoride: Super-p: KS-6: N-methylpyrrolidone = 94:3.5:1.5:1: The mass ratio of 78.6 is weighed, and the preparation steps are as follows. The mixing equipment in the following steps is a double planetary vacuum mixer. The control method of the slurry temperature is to pass into the constant temperature circulating water on the wall of the mixing tank:

[0049] 1) Before preparing the slurry, first bake lithium iron phosphate, conductive agent Super-p and KS-6 at 110°C for 3.7h under vacuum conditions, and bake polyvinylidene fluoride at 78°C for 6.3h under vacuum conditions , the vacuum degree is -0.087MPa, after the baking is completed, the temperature is naturally lowered to below 40°C, and it is set aside;

[0050] 2) Dissolve polyvinylidene fluoride in N-methylpyrrolidone equivalent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com