U-shaped stepping piezoelectric actuator and method based on double-clamping-plate outage locking mechanism

A piezoelectric actuator and locking mechanism technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of increasing the axial size of the actuator, The actuator can not be completed, can not work for a long time, etc., to achieve the effect of improving space utilization, simple structure, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

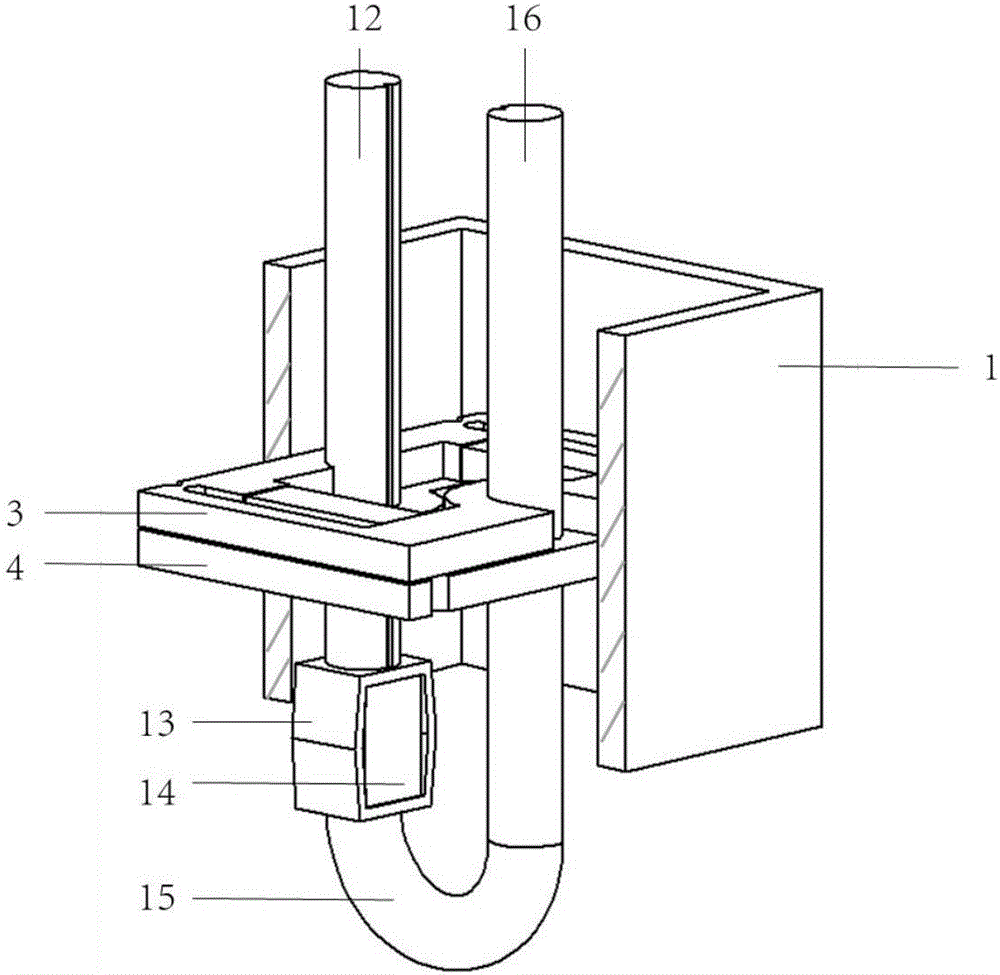

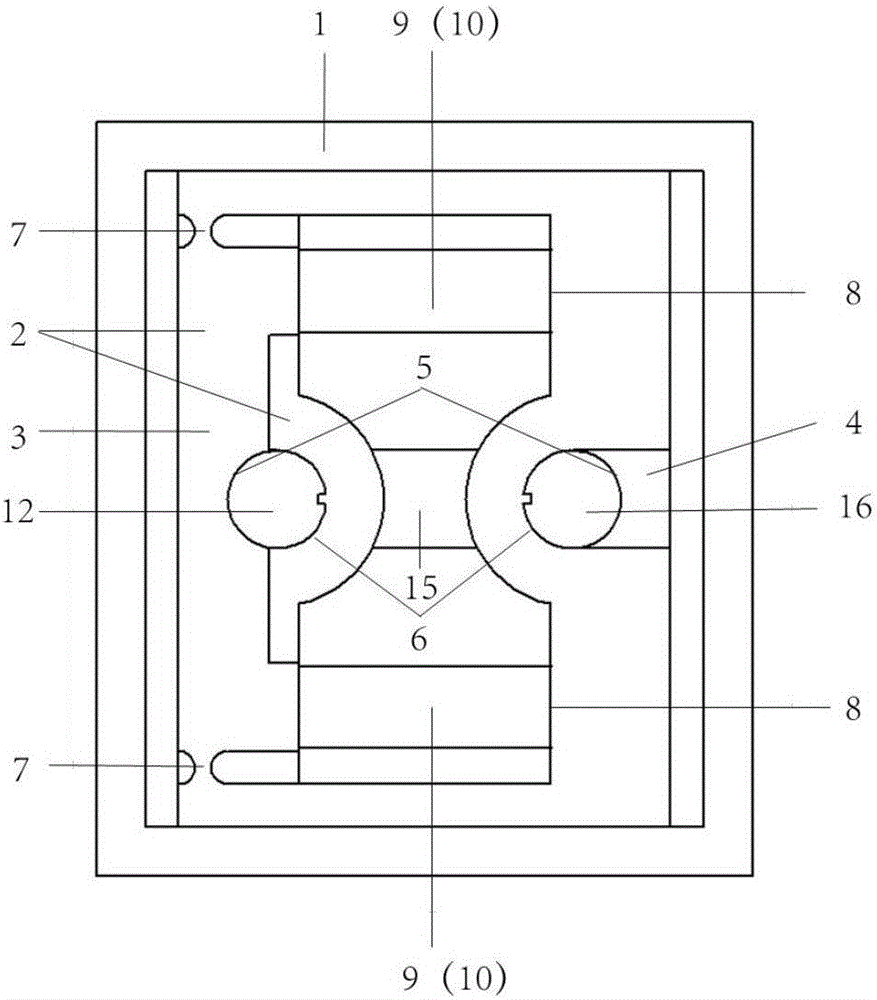

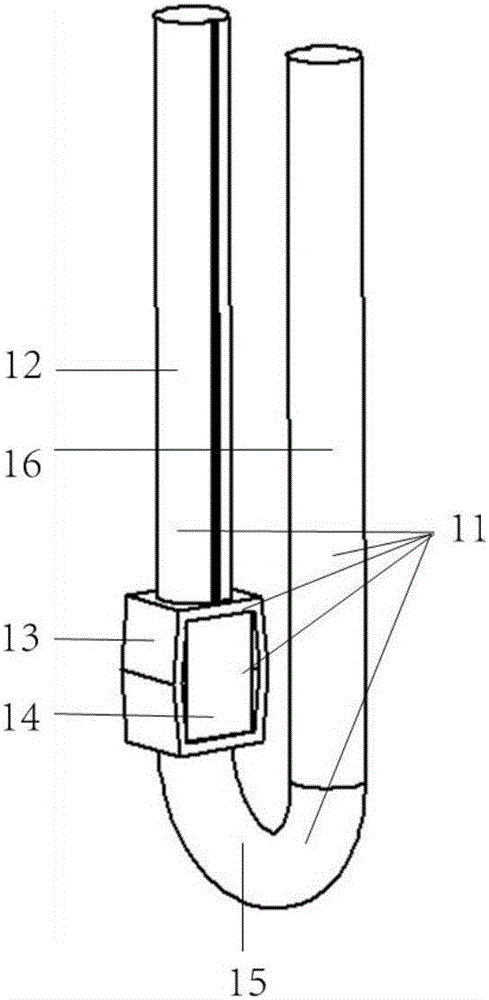

[0025] Such as figure 1 , figure 2 and image 3 As shown, the present invention is based on the U-shaped stepping piezoelectric actuator of the double clamping plate power-off locking mechanism, including a housing 1, a double clamping plate 2 fixed to the housing 1 at both ends, and a double clamping plate passing through the double clamping plate. 2. U-shaped rod 11 with internal clamping hole; double clamping plate 2 is composed of upper clamping plate 3 and lower clamping plate 4 which are inverted and both ends are fixedly connected to shell 1, wherein upper clamping plate 3 and lower clamping plate The clamping plates 4 have the same structure, and are equipped with concave arcs 5, concave circular grooves 6, clamping piezoelectric stack installation places 8 and flexible hinges 7, and the upper clamping piezoelectric stack 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com