Method for electrosparking in atmospheric pressure cold plasma jet

A technology of cold plasma and processing method, applied in the fields of machining and tools, can solve problems such as unreported, and achieve the effects of convenient use, improved discharge state, and increased discharge gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

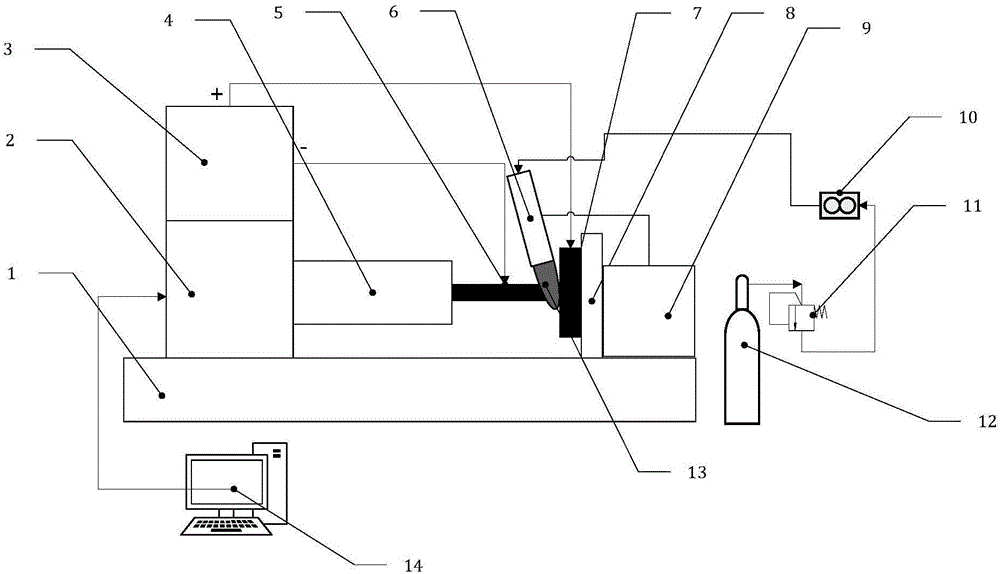

Method used

Image

Examples

Embodiment

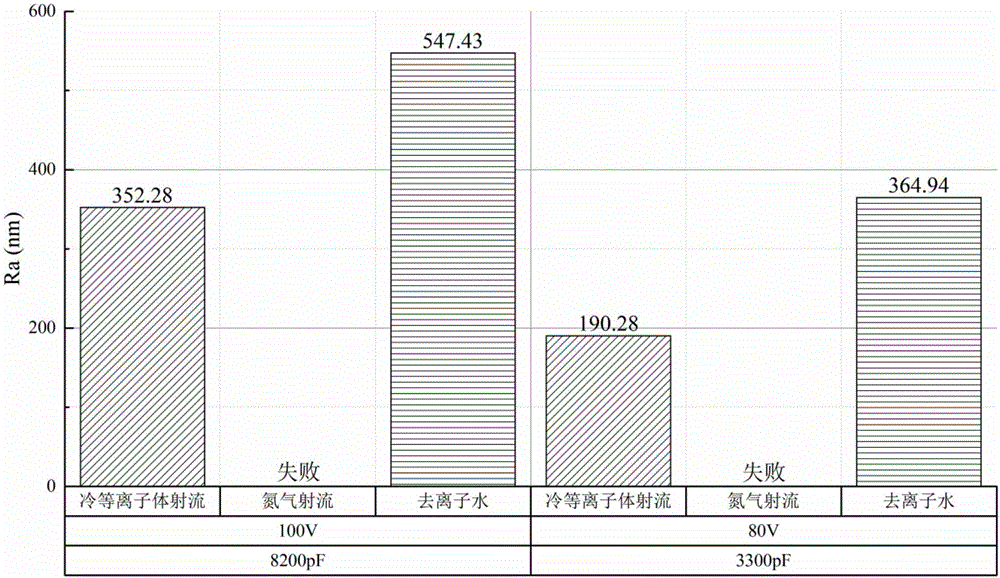

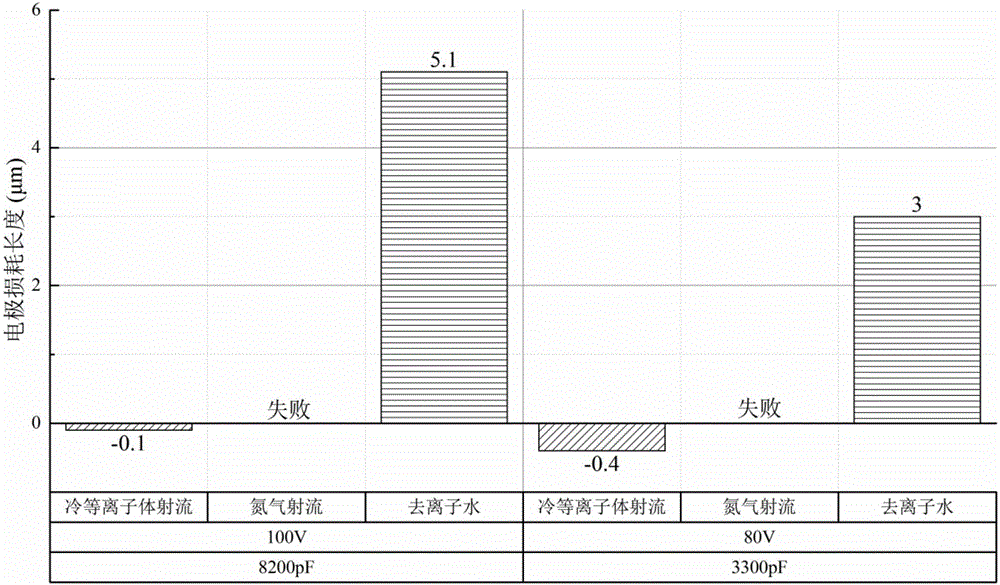

[0022] The characteristics of the cold plasma jet as the EDM medium will be described by combining the EDM micro-groove experiment as an example. The tool electrode material is dock, the workpiece material is H62 brass, and the working gas source is high-purity nitrogen with a purity of 99.999%. The EDM micro-groove machining experiments were carried out in cold plasma jet, nitrogen jet and deionized water respectively. The pulse power supply is RC pulse power supply. The open-circuit voltage of the pulse power supply is set to 80V, and the capacitance values are set to 3300pF and 8200pF respectively. Adjust the output pressure of the pressure reducing valve 11 to 0.3Mpa, and adjust the gas flow quality controller 10 so that the gas flow entering the cold plasma generator 6 is 15slm. Adjust the position of the cold plasma generator 6 so that the end of the tool electrode 5 and the area to be processed of the workpiece 7 are completely submerged in the cold plasma jet 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com