A Welding Process for Dissimilar Steel Joints between Low-Activation Martensitic Steel and 316l Stainless Steel

A martensitic steel, welding process technology, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve the problems of reducing the service performance of dissimilar steel joints, reducing joint performance, and high energy input, and achieving improved Welding efficiency, reduced line energy, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

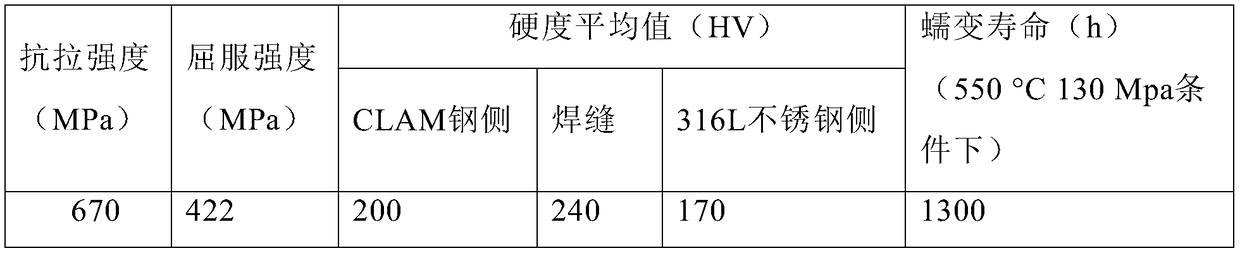

Embodiment 1

[0017] A welding process for CLAM steel and 316L stainless steel dissimilar steel joints, the preparation process of the test plate to be welded before welding, the groove form V-shaped groove angle α=60℃, and the groove bottom gap is 2mm. Welding process and process parameters: the bottom welding layer adopts ER309 welding wire with a diameter of 0.8mm, the current range is 65A, the voltage range is 12V, the welding speed range is 55mm / min, and the argon flow range on the front of the weld bead is 7L / min; the filling layer adopts a diameter of 0.8 mm ER309 welding wire, current range 85A, voltage range 12V, welding speed range 70mm / min, front argon flow range of the weld bead 6L / min; cover welding layer adopts 0.8mm diameter ER309 welding wire, current range 95A, voltage range 12V , The welding speed range is 70mm / min, and the argon gas flow range on the front of the welding bead is 6L / min. During the whole welding process, the argon gas flow on the back of the weld bead is 10...

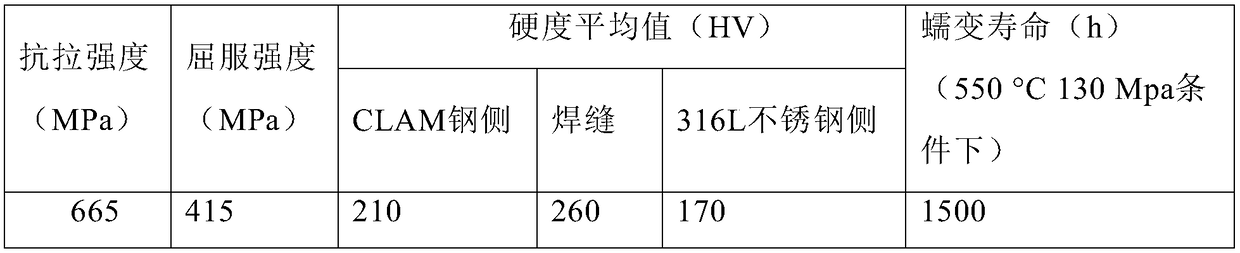

Embodiment 2

[0042] A welding process of CLAM steel and 316L stainless steel dissimilar steel joints, the preparation process of the test plate to be welded before welding, the groove form V-shaped groove angle α=65℃, and the groove bottom gap is 2mm. Welding procedure and process parameters: The bottom welding layer adopts ER309 welding wire with a diameter of 1.0mm, the current range is 75A, the voltage range is 13V, the welding speed range is 65mm / min, and the argon flow range on the front side of the welding bead is 7L / min; the filling welding layer adopts a diameter of 1.0 mm ER309 welding wire, current range 90A, voltage range 14V, welding speed range 70mm / min, front argon flow range of the weld bead 6L / min; cover welding layer adopts 1.0mm diameter ER309 welding wire, current range 100A, voltage range 15V , The welding speed range is 80mm / min, and the argon flow range on the front of the welding bead is 6L / min. During the whole welding process, the argon gas flow on the back of the w...

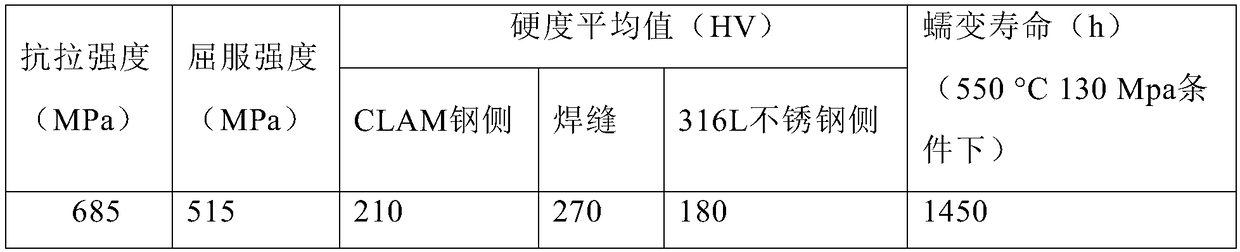

Embodiment 3

[0048] A welding process of CLAM steel and 316L stainless steel dissimilar steel joints, the preparation process of the test plate to be welded before welding, the groove form V-shaped groove angle α=65℃, and the groove bottom gap is 2mm. Welding procedure and process parameters: The bottom welding layer adopts ER309 welding wire with a diameter of 1.2mm, the current range is 85A, the voltage range is 13V, the welding speed range is 70mm / min, and the argon flow range on the front side of the weld bead is 7L / min; the filling layer adopts a diameter of 1.2 mm ER309 welding wire, current range 90A, voltage range 14V, welding speed range 70mm / min, front argon flow range of the weld bead 6L / min; cover welding layer adopts 1.2mm diameter ER309 welding wire, current range 105A, voltage range 15V , The welding speed range is 80mm / min, and the argon flow range on the front of the welding bead is 6L / min. During the whole welding process, the argon gas flow on the back of the weld bead is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com