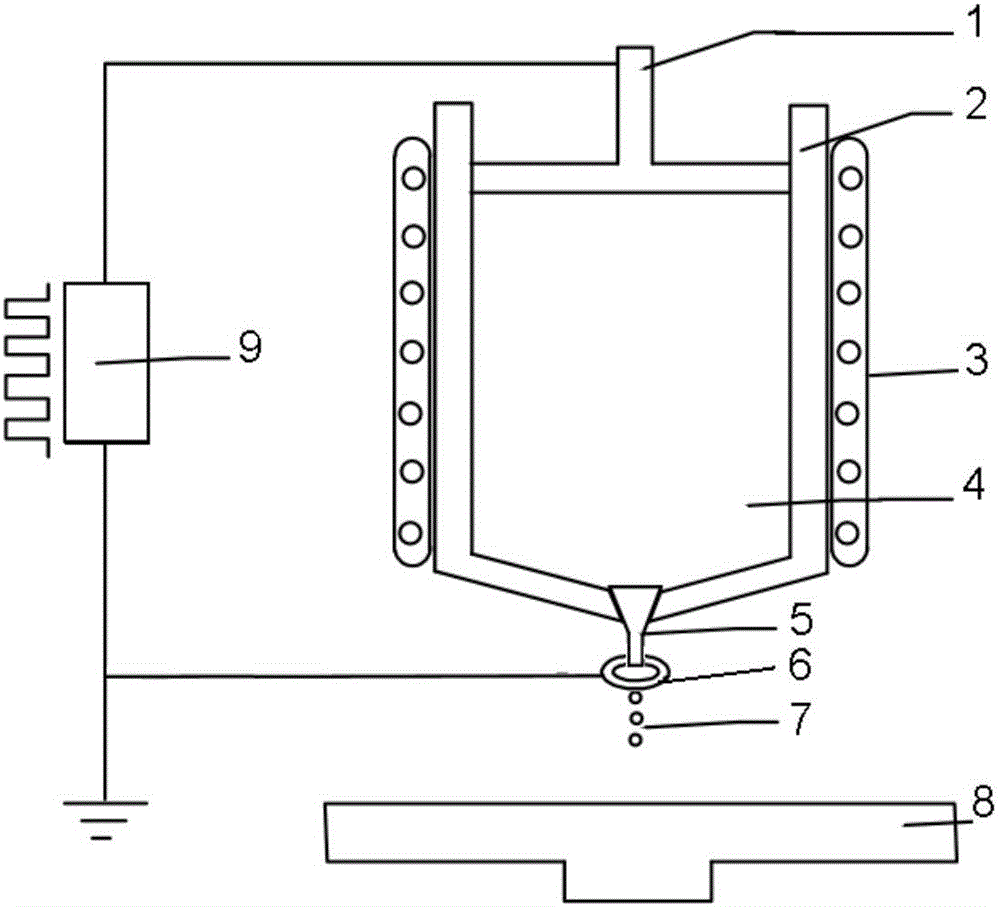

Direct-current pulse-controlled molten drop deposition 3D printing device and printing method

A pulse control, 3D printing technology, applied in the field of 3D printing, can solve the problems of difficulty in improving printing speed and efficiency, large influence of external factors on droplets, slow response speed of melt droplets, etc. Fast, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking aluminum alloy material as an example, the specific steps are as follows:

[0033] Step 1, using computer-aided software to design a three-dimensional part model to be printed, and then performing hierarchical processing on the part model, so as to obtain contour data and filling data of each layer;

[0034] Step 2: Weigh 50.0g of ZL102 aluminum alloy raw material and put it into the crucible, heat it with nickel-chromium electric heating wire, control the temperature to rise to 650°C, so that the sample is fully melted into a uniform melt;

[0035] Step 3: Open the nozzle head, connect the pulse high-voltage generator to 220V power supply and adjust the output voltage to 5.6kV to make the voltage polarity positive, generate a rectangular pulse voltage, and ground the receiving platform.

[0036] Step 4: Turn on the three-dimensional movement device of the forming workbench, adjust the distance between the control nozzle and the workbench to 2cm, and start to fal...

Embodiment 2

[0039] Taking the isotactic polypropylene material as an example, the specific steps are as follows:

[0040] Step 1, using computer-aided software to design a three-dimensional part model to be printed, and then performing hierarchical processing on the part model, so as to obtain contour data and filling data of each layer;

[0041] Step 2, weighing 100 g of isotactic polypropylene particles into a crucible in an induction furnace, and heating to 290° C. through a heating furnace to fully melt the sample into a uniform liquid state;

[0042] Step 3: Open the nozzle head, connect the pulse high-voltage generator to 220V power supply and adjust the output voltage to 5.1kV to make the voltage polarity positive, generate a rectangular pulse voltage, and ground the receiving platform.

[0043] Step 4: Turn on the three-dimensional movement device of the forming workbench, adjust the distance between the control nozzle and the workbench to 2cm, and start to fall at a certain frequen...

Embodiment 3

[0046] Taking ABS plastic as an example, the specific steps are as follows:

[0047] Step 1, using computer-aided software to design a three-dimensional part model to be printed, and then performing hierarchical processing on the part model, so as to obtain contour data and filling data of each layer;

[0048] Step 2, weighing 150 grams of raw material ABS plastic into the crucible in the induction furnace, heating the temperature to 220°C through the heating furnace control, so that the sample is fully melted into a uniform liquid state;

[0049] Step 3: Open the nozzle head, connect the pulse high-voltage generator to 220V power supply and adjust the output voltage to 6kV to make the voltage polarity positive, generate a rectangular pulse voltage, and ground the receiving platform.

[0050] Step 4: Turn on the three-dimensional movement device of the forming workbench, adjust the distance between the control nozzle and the workbench to 2cm, and start to fall at a certain fre...

PUM

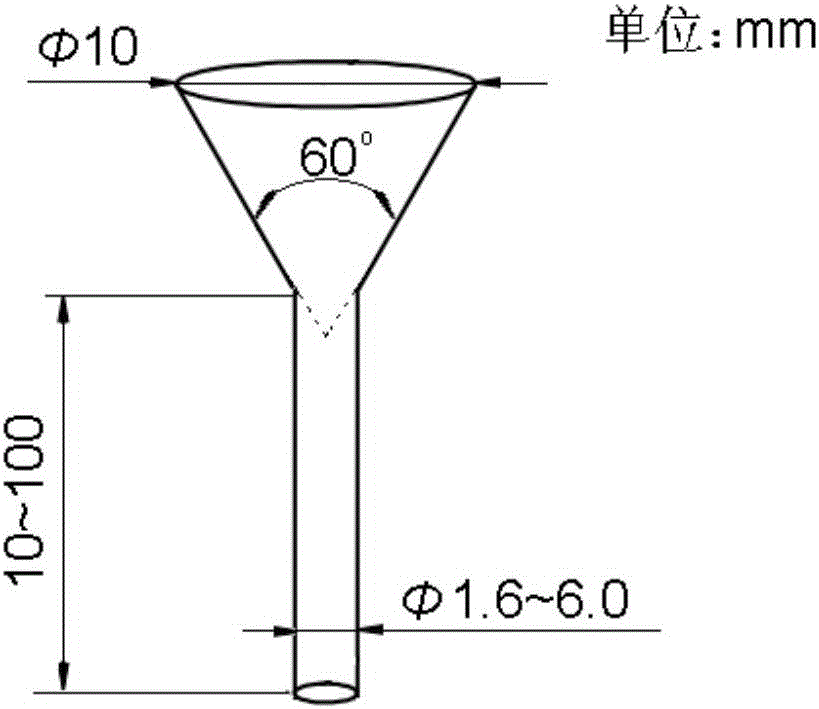

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com