Long-term pressure-resistant insulating angle iron for turnout installation device

An installation device, voltage-resistant insulation technology, applied in the direction of railway signals, transportation and packaging, railway car body parts, etc., can solve the problem of damage to the insulation strength and mechanical strength of insulation parts, the inability to detect cracks and interlayers in key parts, insulation board gaps and Insufficient creepage distance and other issues, to achieve excellent mechanical properties, eliminate electrochemical reactions, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the utility model is described in detail below in conjunction with accompanying drawing.

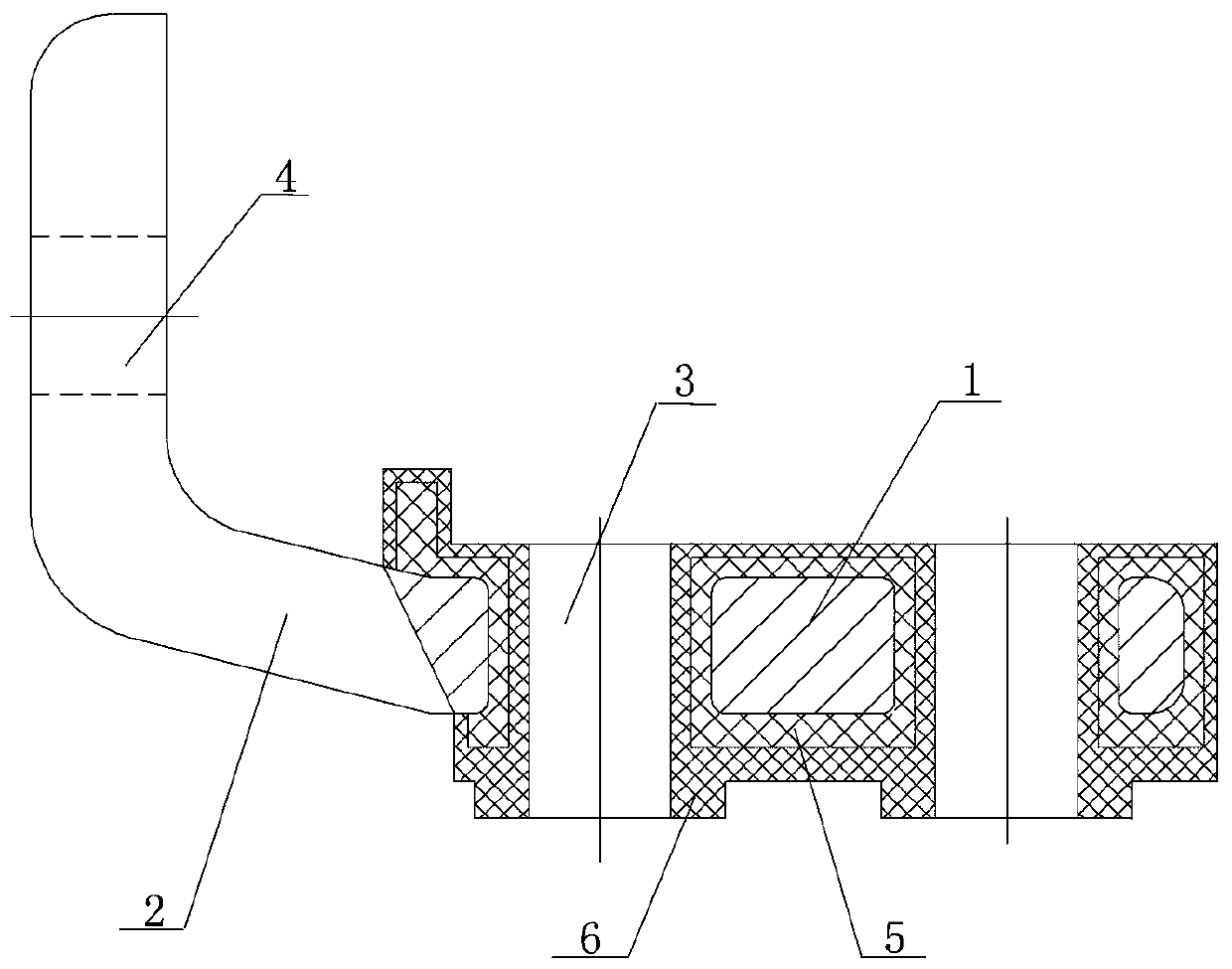

[0017] see figure 1 , a long-term voltage-resistant insulating angle-shaped iron for a turnout installation device, including a fixed iron core 1 in an inline structure and an obtuse-angled connecting iron core 2 arranged at one end of the fixed iron core 1. The connection The iron core 2 is provided with a connection hole 4, and both ends of the fixed iron core 1 are provided with a fixed hole 3, and the inner walls of the fixed iron core 1 and the two fixed holes 3 are all molded with a solidified layer 5. The outside of the solidified layer 5 is covered with a plasticized layer 6 by injection molding.

[0018] The material of the solidified layer is 4330-1 (phenolic glass fiber molding compound for electrical insulation) or BMC (fiber-reinforced unsaturated polyester molding compound for electrical use), and the material of the plasticized layer 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com