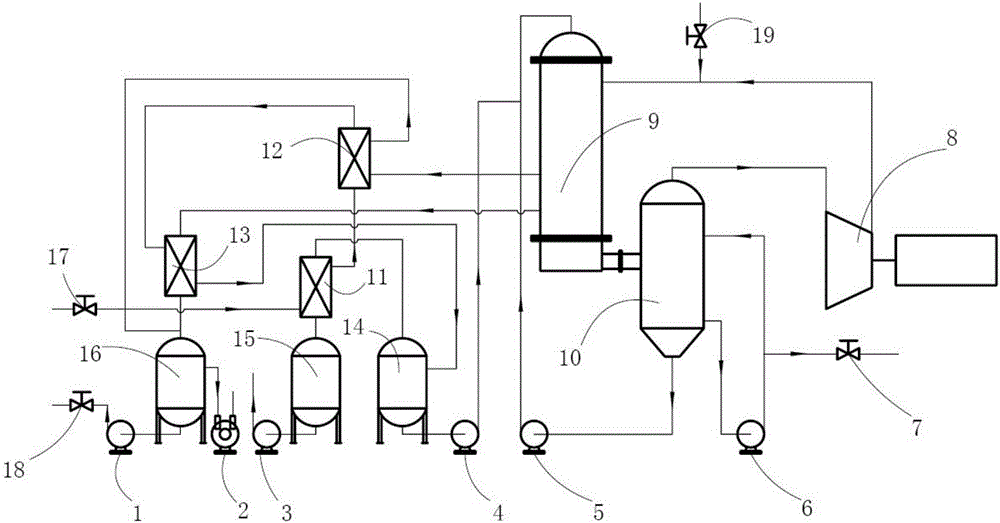

MVR wastewater evaporation and concentration system

An evaporative concentration system, wastewater technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting system efficiency and reliability, blockage of heat exchangers or pipes, etc. , to avoid changes in compressor operating conditions and other operating failures, reduce system energy consumption, and improve applicability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0026] The secondary steam and steam mentioned in the text are all steam of water.

[0027] The present invention comprises an evaporator 9 and a separator 10 through which the raw waste water passes sequentially, the evaporator 9 evaporates the raw waste water, the separator 10 separates the water-gas mixture generated in the evaporator 9, and the separator The concentrated waste liquid generated at the bottom of 10 is returned to the separator 10 through the concentrated water pump 6 to realize the circulation flow, and the secondary steam generated in the separator 10 is pressurized by the water vapor compressor 8 and enters the evaporator 9 to form a A heat source for heating the raw wastewater. Wherein the raw waste water is located at the evaporation side of the evaporator 9 , and the secondary steam is located at the condensation side of the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com