Preparation method and application of biodegradable antifouling resin

An antifouling resin and solvent technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve poor resistance to seawater immersion, short antifouling period, and unstable release of antifouling agents and other problems, to achieve the effects of controlled release, controllable degradation, and excellent resistance to seawater immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

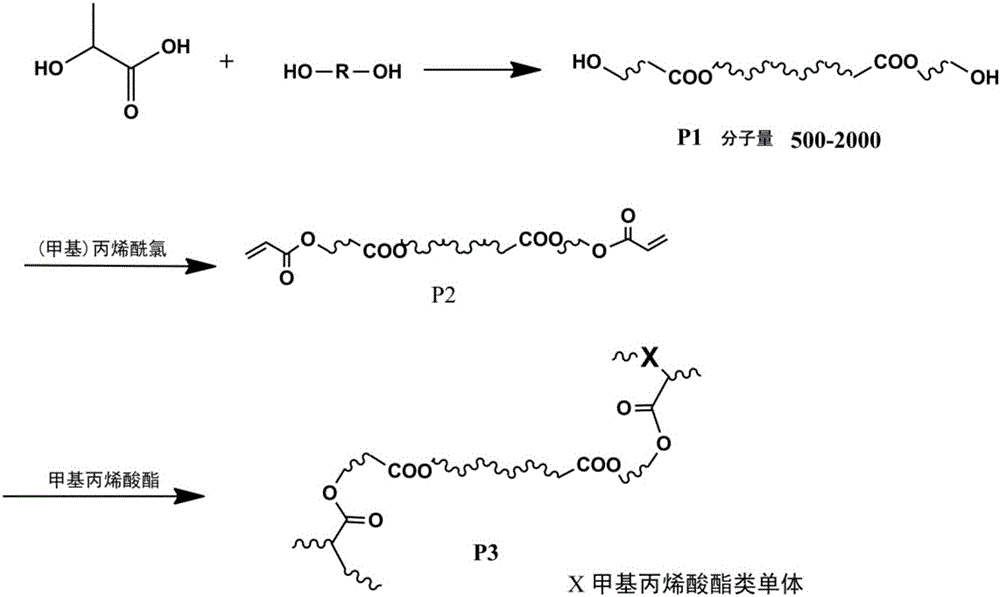

Method used

Image

Examples

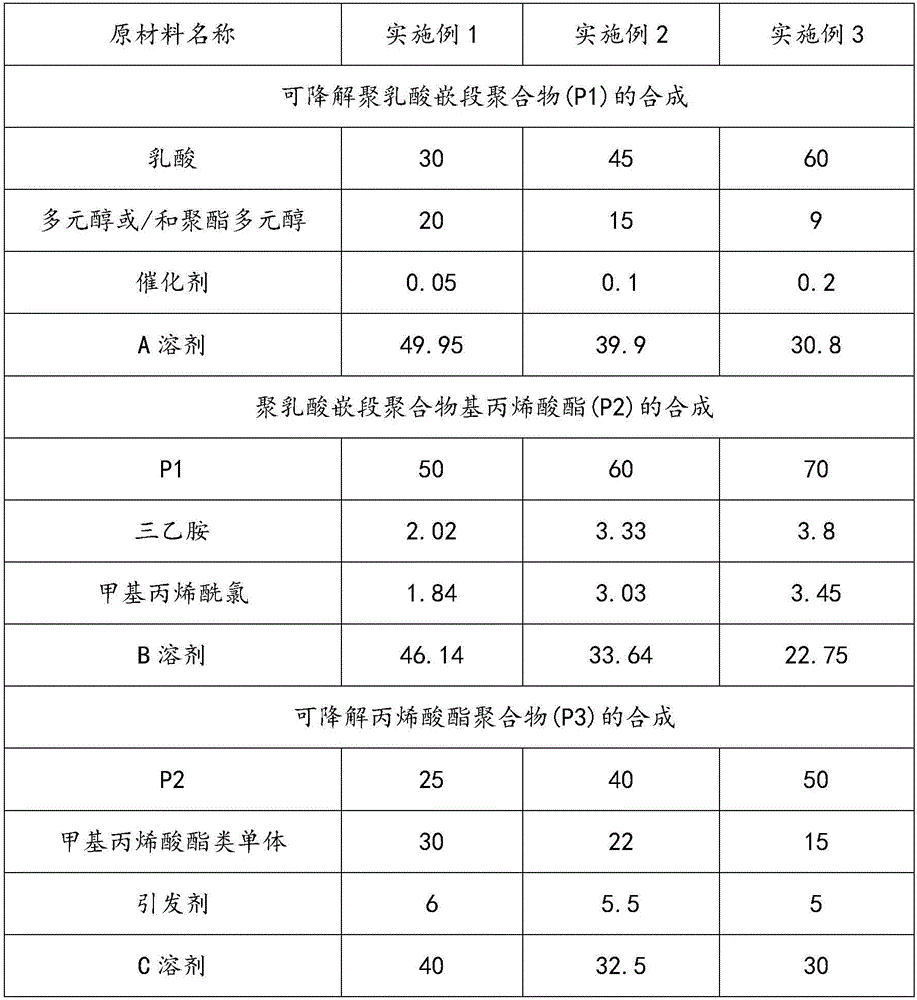

Embodiment 1

[0040] Embodiment 1: catalyst is stannous octoate, A solvent is xylene, B solvent is cyclohexanone, initiator is azobisisobutyronitrile, and C solvent is xylene;

Embodiment 2

[0041] Embodiment 2: catalyzer is tin protochloride, and A solvent is xylene, and B solvent is n-butanol, and initiator is azobisisobutyronitrile, and C solvent is xylene;

Embodiment 3

[0042] Embodiment 3: The catalyst is zinc oxide, the A solvent is xylene, the B solvent is cyclohexanone, the initiator is benzoyl peroxide, and the C solvent is butanone.

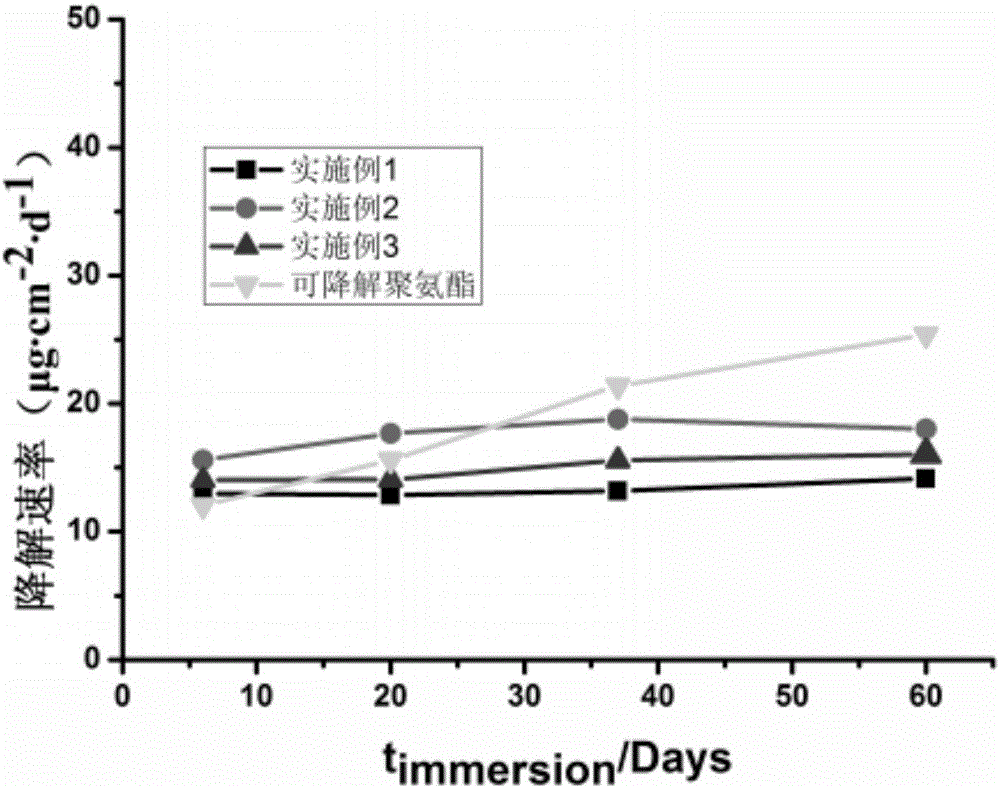

[0043] The applicant tested the performance of the synthesized degradable acrylate polymer (P3), the degradable antifouling resin, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com