A high transparency halogen-free flame retardant material

A flame retardant material, high transparency technology, applied in the field of high transparency halogen-free flame retardant materials, to achieve good practical value and promotion prospects, broaden the application field, and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

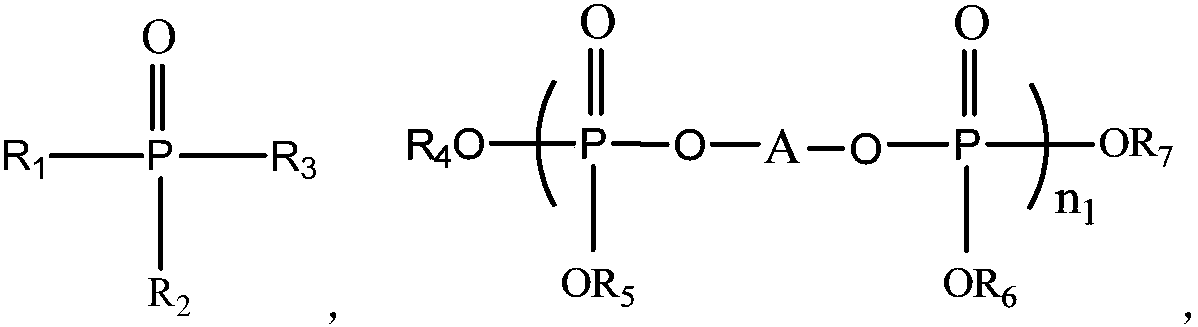

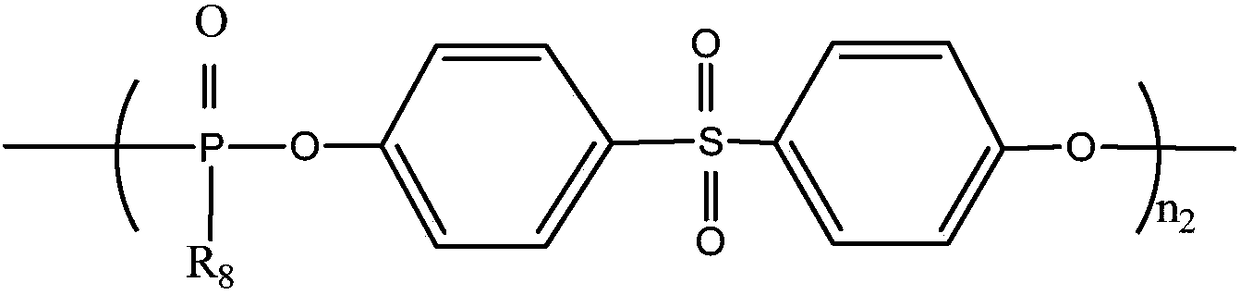

Method used

Image

Examples

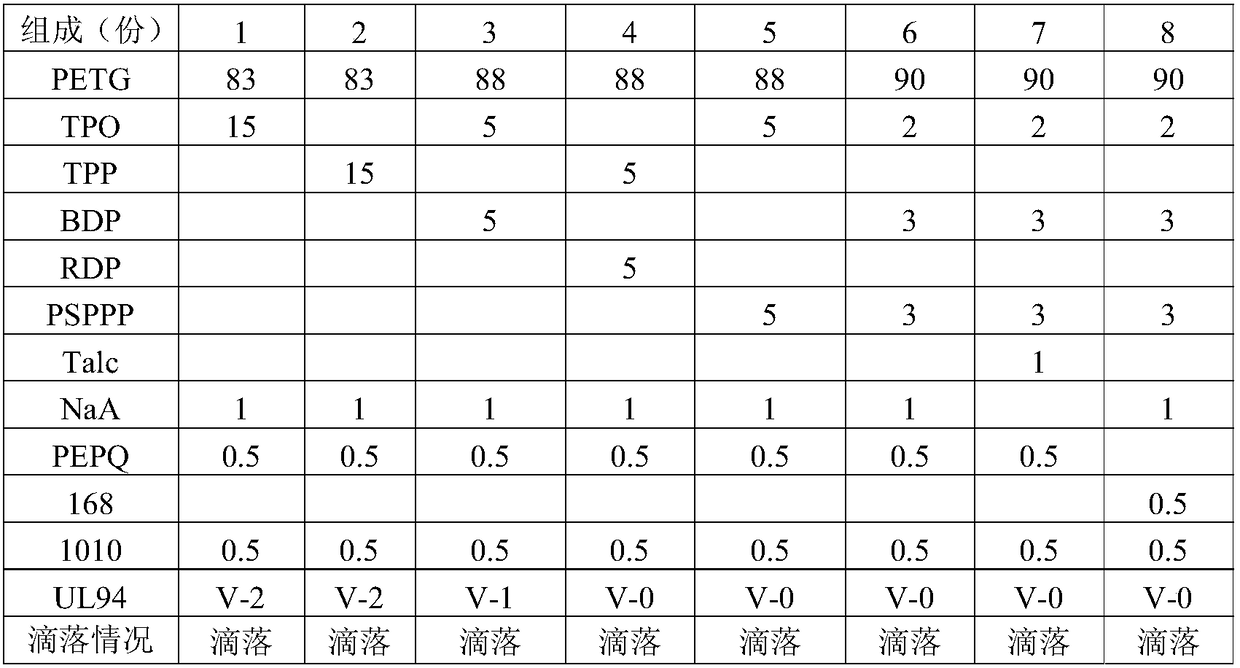

Embodiment 1

[0022] Each raw material is taken by weighing the following proportions by weight:

[0023] Polyethylene terephthalate-1,4-cyclohexanedimethanol PETG 83 parts, flame retardant triphenylphosphine oxide TPO 15 parts, nucleating agent sodium benzoate NaA 1 part, PEPQ antioxidant 0.5 part, 0.5 part of 1010 antioxidant.

[0024] Dry the weighed raw materials, then add them to a high-speed mixer and mix for 10 minutes, take them out, add them to a twin-screw extruder with a melting temperature of 150-240 ° C, extrude, and granulate to obtain the high transparency of the present invention Halogen-free flame retardant material. The process conditions of the twin-screw extruder are: the temperature of the first zone of the extruder is 140-160°C, the temperature of the second zone is 160-180°C, the temperature of the third zone is 180-200°C, the temperature of the fourth zone is 200-220°C, and the temperature of the fifth zone is 220- 240°C, the temperature in the sixth zone is 220-24...

Embodiment 2

[0026] Each raw material is taken by weighing the following proportions by weight:

[0027] 83 parts of polyethylene terephthalate-1,4-cyclohexanedimethanol PETG, 15 parts of flame retardant triphenyl phosphate, 1 part of nucleating agent sodium benzoate NaA, 0.5 part of PEPQ antioxidant, 0.5 part of 1010 antioxidant.

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] Each raw material is taken by weighing the following proportions by weight:

[0031] Polyethylene terephthalate-1,4-cyclohexanedimethanol PETG 88 parts, flame retardant triphenylphosphine oxide TPO 5 parts, flame retardant bisphenol A-bis(diphenyl phosphate ) 5 parts of BDP, 1 part of nucleating agent sodium benzoate, 0.5 part of PEPQ antioxidant, and 0.5 part of 1010 antioxidant.

[0032] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com