Thermal insulation coating for exterior wall of building

A technology for thermal insulation coatings and building exterior walls, which is applied in the field of coatings and can solve problems such as poor adhesion, limited thermal insulation effect, and poor coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

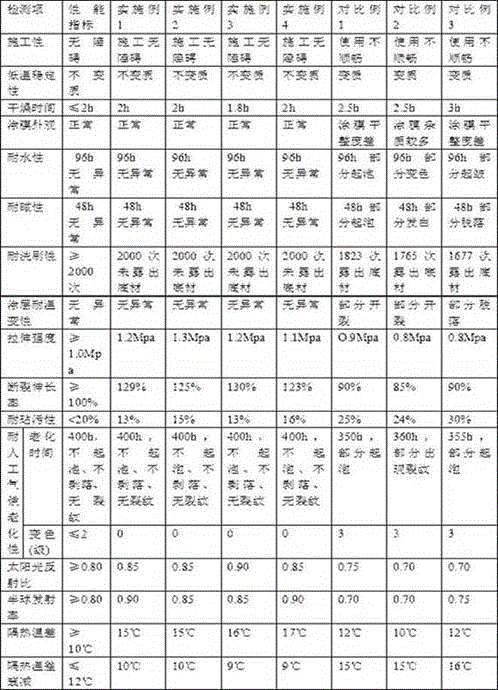

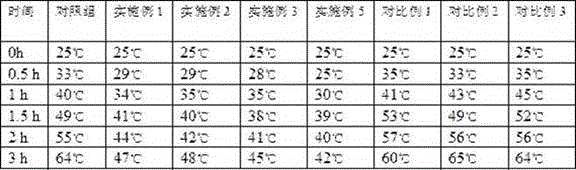

Examples

Embodiment 1

[0019] A heat-insulating coating for building exterior walls, comprising 45 parts of base emulsion, 8 parts of glass microspheres, 7 parts of titanium dioxide, 7 parts of filler, 8 parts of water, 8 parts of film-forming aid, 0.1 part of leveling agent, thickener 0.5 parts of agent, 0.4 parts of wetting agent, 0.4 parts of dispersant, 0.1 part of antifoaming agent and 0.3 parts of pH regulator. The base emulsion is a copolymer emulsion of fluoroolefin and vinyl ester, with a fluorine content of 20% and a solid content of 45%; the filler is a mixture of talcum powder, nano tin oxide and nano antimony oxide; the thickener It is an alkali-swellable thickener, the film-forming aid is ethyl 3-ethoxy propionate; the pH regulator is dimethylethanolamine, and the dispersant is sodium polycarboxylate.

Embodiment 2

[0021] A heat-insulating coating for building exterior walls, the main material and ingredients are mixed at a ratio of 5:1, and the main material includes 60 parts of base emulsion, 12 parts of glass microspheres, 10 parts of titanium dioxide, 12 parts of filler, 13 parts of water, and 13 parts of membrane aids, 0.3 parts of leveling agents, 1.5 parts of thickeners, 1 part of wetting agents, 0.8 parts of dispersants and 0.3 parts of defoamers, 0.5 parts of pH regulators, 1 part of nano-scale titanium dioxide and nano-zinc oxide 1 serving. The base emulsion is a copolymer emulsion of fluoroolefin and vinyl ester, the fluorine content is 25%, and the solid content is 55%; the filler is a mixture of talcum powder, calcium carbonate, nano-tin oxide and nano-antimony oxide; The thickener is an alkali-swellable thickener, the film-forming aid is ethyl 3-ethoxy propionate; the pH regulator is dimethylethanolamine, and the dispersant is sodium polycarboxylate. The ingredients includ...

Embodiment 3

[0023] A heat-insulating paint for building exterior walls, the main material and ingredients are mixed at a weight ratio of 8:1, and the main material includes 50 parts of base emulsion, 9 parts of glass microspheres, 8 parts of titanium dioxide, 10 parts of filler, and 12 parts of water parts, 10 parts of film-forming aids, 0.2 parts of leveling agents, 0.8 parts of thickeners, 0.6 parts of wetting agents, 0.6 parts of dispersants and 0.2 parts of defoamers, 0.4 parts of pH regulators, 0.5 parts of nano-sized titanium dioxide, 0.5 parts of nanometer zinc oxide. The ingredients include 65 parts by weight of water-based isocyanate and 35 parts by weight of propylene glycol methyl ether acetate. The base emulsion in the main material is a copolymer emulsion of fluoroolefin and vinyl ester, the fluorine content is 22%, and the solid content is 50%; the filler is a mixture of kaolin, calcium carbonate, and nano-tin oxide; the thickener The agent is an alkali-swellable thickener,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com