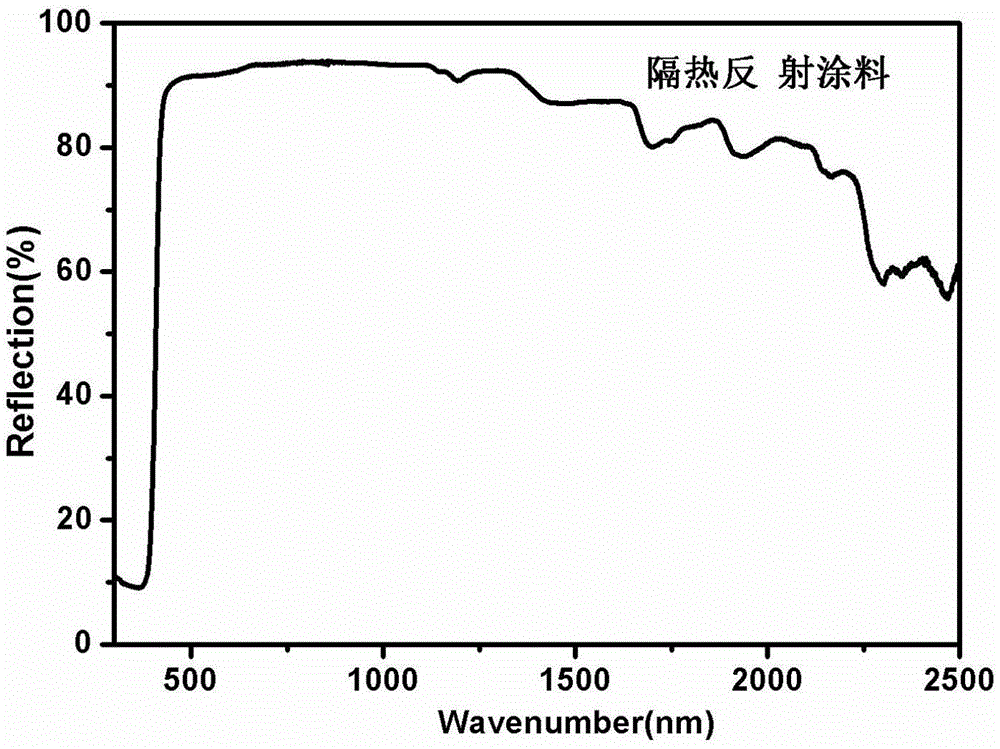

Coating with heat insulation reflection function and preparation method thereof

A technology of thermal insulation reflection and functional materials, applied in the field of coatings, can solve the problems of poor thermal insulation reflection function, single paint color, high energy consumption, etc., and achieve the effect of easy construction, good hand feel, and enhanced coating life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

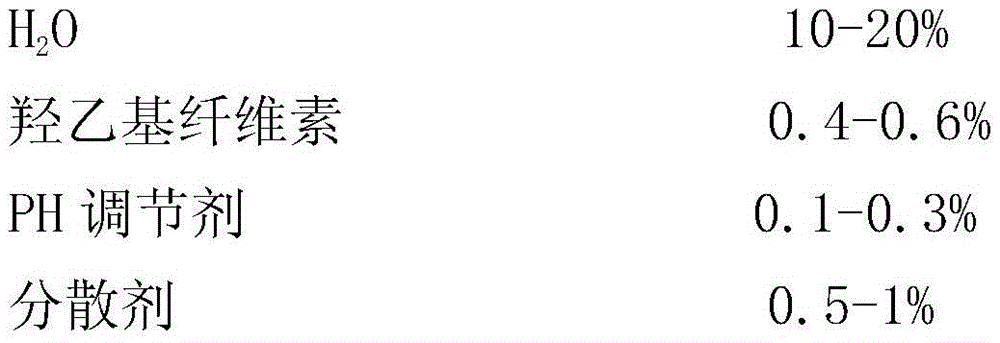

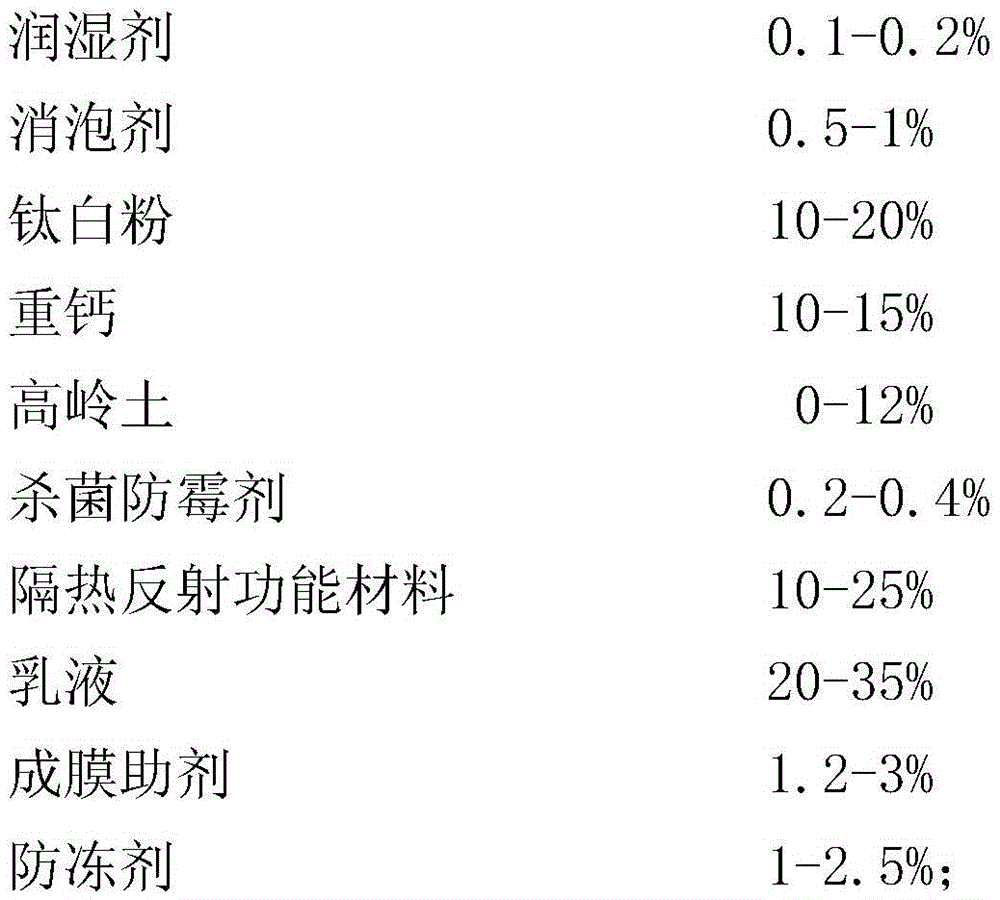

[0028] A coating with heat insulation and reflection function, which is prepared from the following components in the following mass fraction ratio:

[0029]

[0030]

[0031] The heat-insulating reflective functional material is polystyrene core-titanium dioxide shell hybrid particles; the emulsion is one of pure acrylic emulsion, silicon acrylic emulsion or vinegar acrylic emulsion; the kaolin is calcined kaolin or washed kaolin or both Mix as you like.

[0032] The polystyrene core-titanium dioxide shell hybrid particle is prepared according to the following method:

[0033] (A) Preparation of polystyrene microspheres:

[0034] Add a certain amount of water into the reactor, raise the temperature to 60-90°C, add styrene, acrylic monomer and initiator dropwise, keep the temperature at 60-90°C for 4-12h after the addition, and then centrifuge , washing and drying to obtain polystyrene microspheres, wherein the mass ratio of styrene to water is 1:15-1:30, the mass rati...

Embodiment 1

[0044] Embodiment 1: A kind of coating with heat-insulating reflective function, it is formulated by following components by following mass fraction ratio:

[0045]

[0046]

[0047] The heat-insulating reflective functional material is polystyrene core-titanium dioxide shell hybrid particles.

[0048]The preparation method of the coating with heat insulation reflection function described in this embodiment is prepared according to the following method:

[0049] (1) At a speed less than 500r / min, add water, hydroxyethyl cellulose, and pH regulator in order to disperse for 1 min;

[0050] (2) Increase the speed to 800r / min, first add wetting agent, dispersant, defoamer, anti-fungal agent in sequence, then add titanium dioxide, heavy calcium, calcined kaolin and heat-insulating and reflective functional materials, and then increase the speed to 1800r / min, disperse for 20min;

[0051] (3) Reduce the rotating speed to 1000r / min, add emulsion, film-forming aid, and antifre...

Embodiment 2

[0052] Embodiment 2: A kind of coating with heat-insulating reflective function, it is formulated by following components by following mass fraction ratio:

[0053]

[0054] The heat-insulating reflective functional material is polystyrene core-titanium dioxide shell hybrid particles.

[0055] The preparation method of the coating with heat insulation reflection function described in this embodiment is prepared according to the following method:

[0056] (1) At a speed less than 500r / min, add water, hydroxyethyl cellulose, and pH regulator in order to disperse for 3 minutes;

[0057] (2) Increase the speed to 900r / min, first add wetting agent, dispersant, defoamer, bactericide and antifungal agent in sequence, then add titanium dioxide, heavy calcium, calcined kaolin and heat-insulating and reflective functional materials, and then increase the speed to 1900r / min, disperse for 18min;

[0058] (3) Reduce the rotating speed to 1100r / min, add emulsion, film-forming aid, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com