Coating with thermal insulation and reflection functions

A technology of heat insulation reflection and function, applied in the direction of reflection/signal paint, fireproof paint, coating, etc., can solve the problems of unstable reflection heat insulation performance, increase construction difficulty, poor adhesion, etc., and achieve excellent anti-settling performance, Good uniformity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

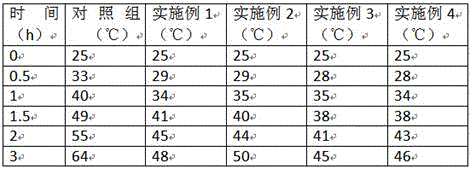

Examples

Embodiment 1

[0021] A coating with a heat-insulating and reflecting function, comprising main ingredients, the main ingredients including the following components by weight: 58 parts of base emulsion, 10 parts of glass microspheres, 10 parts of titanium dioxide, 8 parts of filler, 8 parts of water, Auxiliary (3 parts of film-forming aid, 2 parts of thickener, 2 parts of dispersant and 3 parts of pH regulator) 10 parts;

[0022] The film-forming aid is ethyl 3-ethoxy propionate, the thickener is an alkali-swellable thickener, the dispersant is polycarboxylate sodium salt, and the pH regulator is dimethylethanolamine;

[0023] The glass microspheres are borosilicate glass microspheres, and the particle diameter of the glass microspheres is 21-25 μm;

[0024] The base emulsion is a copolymer emulsion of fluoroolefin and vinyl ester, and the fluorine content is 25%;

[0025] The filler is a mixture of filler 1 and filler 2 in a weight ratio of 1:3, the filler 1 is talcum powder, and the fille...

Embodiment 2

[0027] A coating with heat insulation and reflection function, including main ingredients and ingredients added to the main ingredients before the coating is used. The main ingredients and ingredients are generally mixed according to the ratio of 5-8:1, and this embodiment is mixed according to 6:1 .

[0028] The main ingredients include the following components in parts by weight: 60 parts of base emulsion, 12 parts of glass microspheres, 7 parts of titanium dioxide, 7 parts of filler, 13 parts of water, and 20 parts of additives;

[0029] Auxiliaries include film-forming aids, leveling agents, thickeners, wetting agents, dispersants and defoamers, and pH regulators. The film-forming aids are 3-ethoxy ethyl propionate, and the leveling agents are Silicone leveling agent, the thickener is alkali-swellable thickener, the wetting agent is GSK-588 from Goss, the dispersant is polycarboxylate sodium salt, the defoamer is pH regulator and dimethylethanolamine;

[0030] The base em...

Embodiment 3

[0035] A paint with heat-insulating and reflective function, including main ingredients and ingredients added to the main ingredients before the paint is used, mixed according to 5:1.

[0036] The main ingredients include the following components by weight: 45 parts of base emulsion, 8-12 parts of glass microspheres, 7-10 parts of titanium dioxide, 7-12 parts of filler, 8 parts of water, and 10-20 parts of additives;

[0037] Auxiliaries include film-forming aids, leveling agents, thickeners, wetting agents, dispersants and defoamers, and pH regulators. The film-forming aids are 3-ethoxy ethyl propionate, and the leveling agents are Silicone leveling agent, the thickener is alkali-swellable thickener, the wetting agent is GSK-588 from Goss, the dispersant is polycarboxylate sodium salt, the defoamer is pH regulator and dimethylethanolamine;

[0038] The base emulsion is a copolymer emulsion of fluoroolefin and vinyl ester, and the fluorine content is 25%;

[0039] Described f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com