Rolling oil composition soluble in degreasing agent and application of composition

A technology for rolling oil and degreasing agent, applied in the field of rolling oil composition, can solve the problems of affecting the service life of degreasing agent, poor separation performance of rolling oil and degreasing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

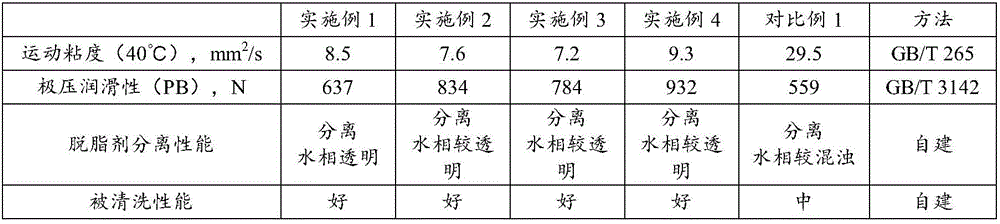

Examples

Embodiment 1~4

[0025] Add component a) and component b), and when heated to 55-60°C, add the remaining additives, maintain the temperature at 55-60°C, stir at constant temperature for more than 1 hour until the product is uniform and transparent, take samples for analysis, and fill.

Embodiment 1

[0027] components parts by weight II-2 69.48 D140 25 isooctyl palmitate 3 tributyl phosphate 2 Propylene oxide diamine condensation polymer 0.02 N-Phenylnaphthylamine 0.5

Embodiment 2

[0029] components parts by weight 50N 91.50 Isooctyl stearate 2 Dibutyl phthalate 2 pentaerythritol oleate 1.2 Di-n-butyl phosphite 2 tricresyl phosphate 1 Polyether silicone oil comb copolymer 0.05 alkenyl succinic acid 0.05 Alkyl dianiline 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com