Method for forming gradient nano-structure surface layer on austenitic stainless steel and controlling content of martensite in gradient nano-structure surface layer

An austenitic stainless steel and nanostructure technology, which is applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult to control martensite, large surface roughness, gradient nano-layer and thin hardened layer, etc. The effect of strengthening layer thickness, high surface quality and large plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

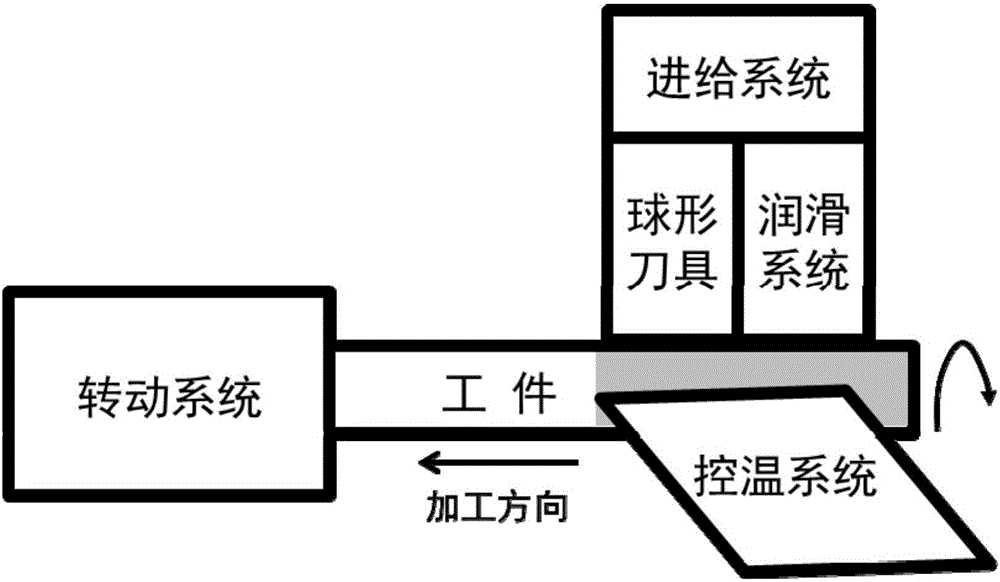

Method used

Image

Examples

Embodiment 1

[0054] Process 316L austenitic stainless steel cylindrical workpiece with a diameter of 10mm, its chemical composition is (mass percentage): C 0.03%, Si 0.03%, Cr 16.72%, Ni 10.7%, Mn 1.01%, Mo 2.12%, S0.016 %, P 0.042%, Fe is the balance;

[0055] 316L stainless steel stacking fault energy: about 40mJ / m 2 ;

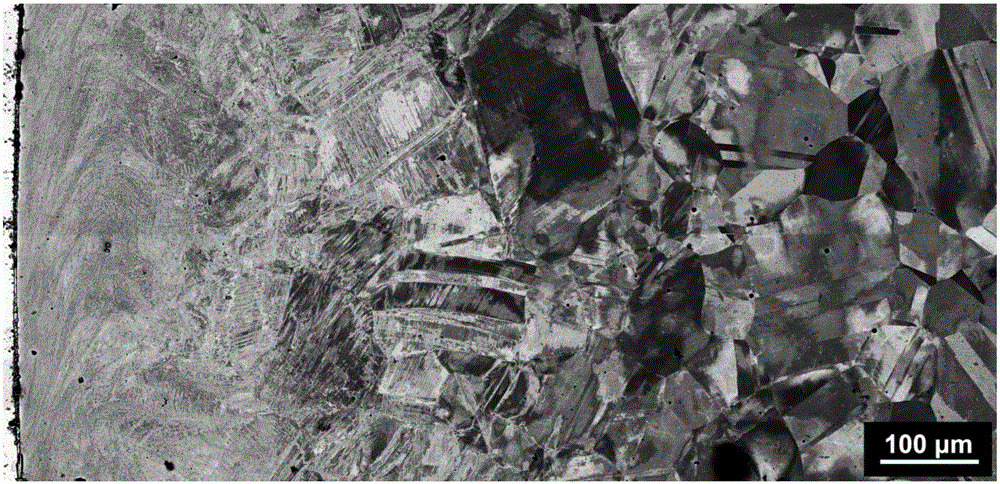

[0056] Original grain size before processing: about 100μm;

[0057] Structure before processing: pure austenite structure;

[0058] Equipment: CNC lathe;

[0059] Spindle (processed workpiece) speed V 1 : 360r / min;

[0060] Spherical rolling tool diameter: 8mm;

[0061] Processing passes: 6 times;

[0062] The amount of pressing a p : 40μm;

[0063] Axial feed speed V 2 : 9mm / min;

[0064] Processing temperature: 22°C.

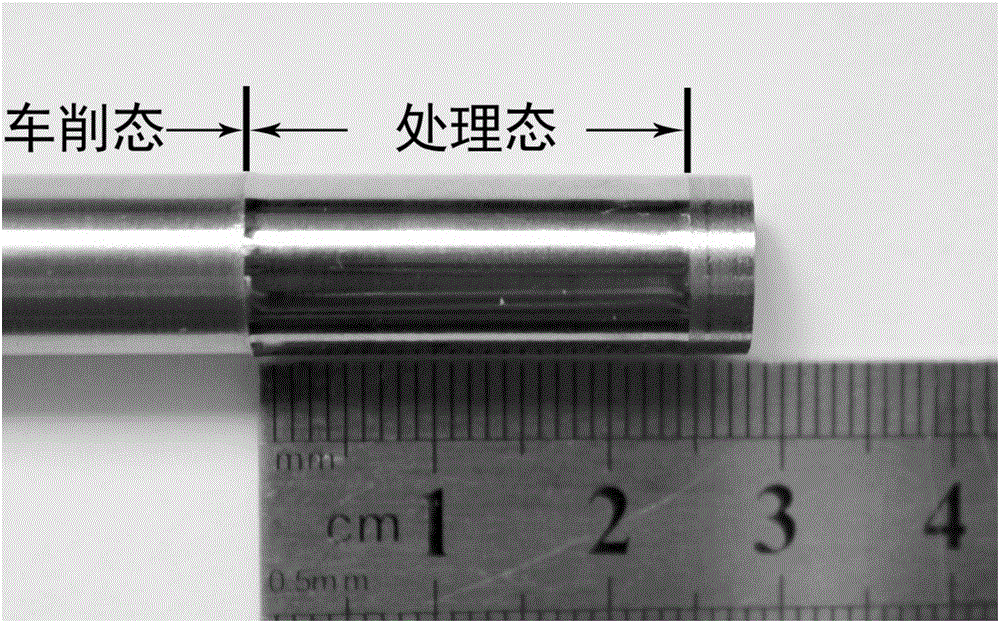

[0065] The surface smoothness of the processed sample in this embodiment is better than that of the finish turning state (such as figure 2 ). The cross-sectional morphology of 316L austenitic stainless steel after 6-pass treatment is as foll...

Embodiment 2

[0067] Heat treatment 316L austenitic stainless steel cylindrical workpiece, its chemical composition and initial state are the same as embodiment 1.

[0068] Equipment: CNC lathe;

[0069] Spindle (processed workpiece) speed V 1 : 360r / min;

[0070] Spherical rolling tool diameter: 8mm;

[0071] Processing passes: 5 times;

[0072] The amount of pressing a p : 40μm;

[0073] Axial feed speed V 2 : 9mm / min;

[0074] Heating device: hot air blower (heatable range 0 ~ 600 ℃);

[0075] Temperature measuring device: K-type thermocouple, digital display thermometer;

[0076] Processing temperature: 85°C;

[0077] After the 316L austenitic stainless steel shaft workpiece is treated by SMRT surface nano-treatment at a temperature of 85 °C, the surface finish of the treated state is better than that of the fine-turned state (such as Figure 7 ). The cross-sectional morphology of the 5-pass treatment was characterized under the scanning electron microscope as follows: Figu...

Embodiment 3

[0079] Heat treatment 316L austenitic stainless steel cylindrical workpiece, its chemical composition and initial state are the same as embodiment 1.

[0080] Equipment: CNC lathe;

[0081] Spindle (processed workpiece) speed V 1 : 360r / min;

[0082] Spherical rolling tool diameter: 8mm;

[0083] Processing passes: 4 times;

[0084] The amount of pressing a p : 40μm;

[0085] Axial feed speed V 2 : 9mm / min;

[0086] Heating device: hot air blower (heatable range 0 ~ 600 ℃);

[0087] Temperature measuring device: K-type thermocouple, digital display thermometer;

[0088] Processing temperature: 175°C;

[0089] The cross-sectional morphology of the 316L austenitic stainless steel shaft workpiece after 4-pass SMRT treatment at a temperature of 175 ° C is characterized under the scanning electron microscope as follows Figure 10 As shown, the thickness of the 316L stainless steel gradient refinement layer exceeds 700 μm, and the entire gradient structure includes: deform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com