Carboxymethylcellulose warp yarn sizing agent containing 4-nitroindole

A technology of carboxymethyl cellulose and nitroindole, applied in fiber type, fiber treatment, plant fiber, etc., can solve the problems of unsatisfactory sizing performance, complex raw material components, high viscosity of slurry, etc., and achieve high Market processing potential, low price, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

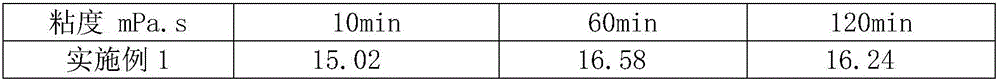

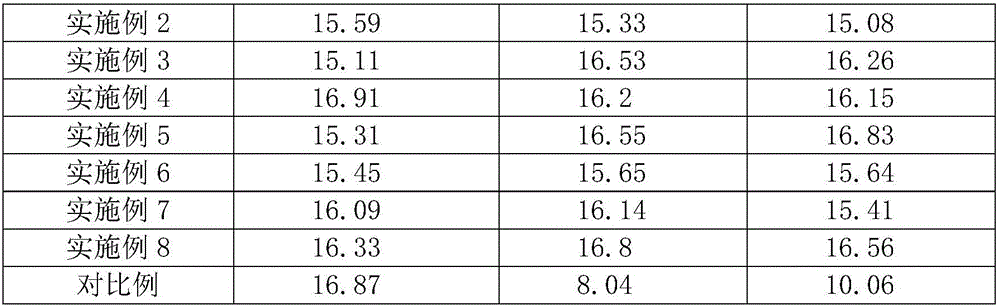

Examples

Embodiment 1

[0031] A carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole is composed of carboxymethyl cellulose, 4-nitroindole and water, and its mass ratio is 10:0.1:100; its preparation method is Mix carboxymethyl cellulose and water according to the mass ratio, add 4-nitroindole crystals, and leave to stand at 10°C for 30 hours after stirring (the stirring speed of the stirring is 30 rpm, and the stirring time is 20 Minutes) rapid stirring (the stirring speed of described rapid stirring is 2000 rev / mins, and stirring time is 5 minutes) after leaving standstill finishes and obtains the carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole.

Embodiment 2

[0033]A carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole is composed of carboxymethyl cellulose, 4-nitroindole and water, and its mass ratio is 15:0.2:100; its preparation method is After mixing carboxymethyl cellulose and water according to the mass ratio, add 4-nitroindole crystals, and after stirring, let it stand at 12°C for 35 hours (the stirring speed of the stirring is 45 rpm, and the stirring time is 25 Minutes) rapid stirring after standing (the stirring speed of the rapid stirring is 2500 rev / min, and the stirring time is 7 minutes) to obtain the carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole.

Embodiment 3

[0035] A carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole is composed of carboxymethyl cellulose, 4-nitroindole and water, and its mass ratio is 10:0.2:100; its preparation method is After mixing carboxymethyl cellulose and water according to the mass ratio, add 4-nitroindole crystals, and after stirring, let it stand at a temperature of 10°C for 35 hours (the stirring speed of the stirring is 30 rpm, and the stirring time is 25 Minutes) rapid stirring after standing (the stirring speed of the rapid stirring is 2000 rev / min, and the stirring time is 7 minutes) to obtain the carboxymethyl cellulose warp yarn sizing agent containing 4-nitroindole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com