Heat pipe and preparation method thereof

A technology of heat pipes and copper pipes, which is applied in the field of heat pipes and their preparation, can solve the problems that the heat dissipation requirements of chip circuits cannot be met, the life of the chip circuit is troubled by the machine, and the inability to conduct effective heat transfer can be solved. It achieves good conductivity and ductility, Good thermal conductivity, the effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

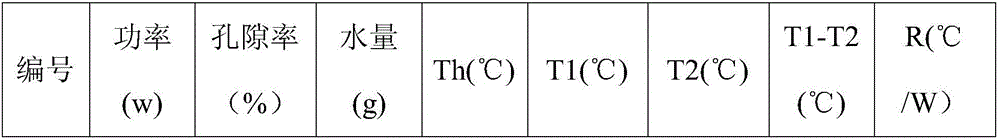

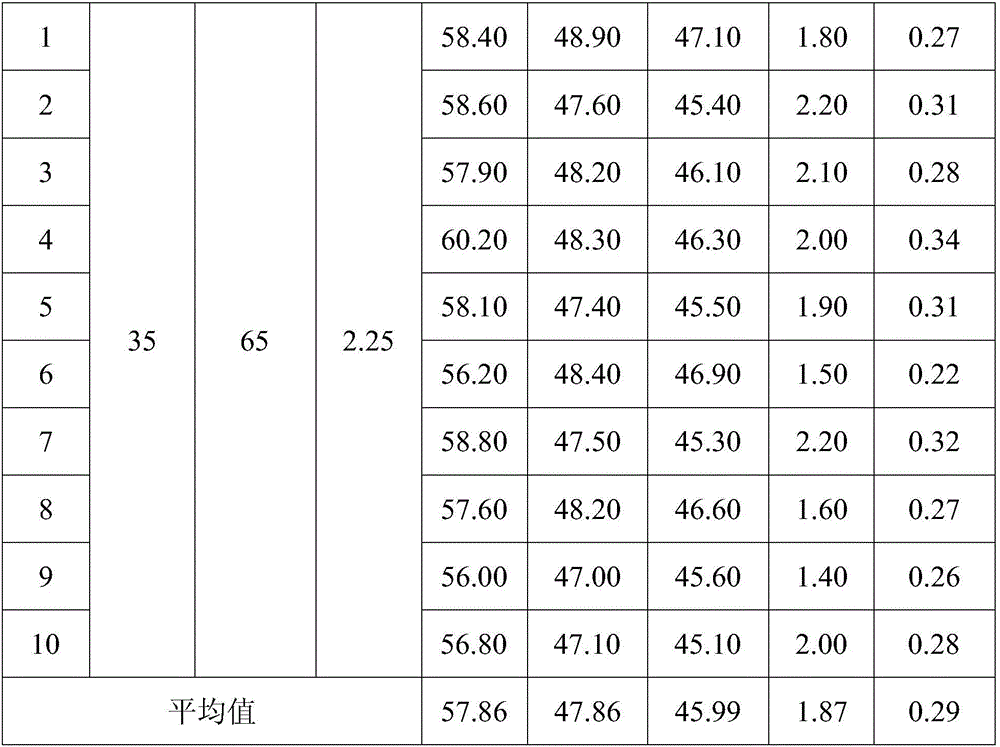

[0023] The technical solutions of the present invention will be further described below through specific embodiments.

[0024] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

[0025] Adopt the preparation method of the present invention to prepare heat pipe, this preparation method comprises the following steps:

[0026] 1) Cleaning, cleaning the copper pipe with a hydrocarbon cleaning agent to remove the oil on the inner wall of the copper pipe;

[0027] 2) Powder filling, the center core of the copper tube is fixed with a central rod, and 40% of water atomized copper powder and 60% of foamed copper powder are mixed evenly and filled into the copper tube, wherein the water atomized copper The particle size meshes of powder and foamed copper powder are both 100 mesh;

[0028] 3) Sintering, place the powder-filled copper tube in a sintering furnace for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com