Quantitative analysis method for mixing uniformity of raw materials of supercapacitor electrode

A supercapacitor, mixing uniformity technology, applied in material analysis using neutrons, material analysis using wave/particle radiation, and material analysis, etc., can solve the problem of insufficient slurry dispersion uniformity, low mixing efficiency, and coating stickiness Insufficient knots, etc., to solve the effect of low pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 880 grams of activated carbon for supercapacitor and place it in a stainless steel reaction kettle, and successfully label the activated carbon with 1 gram of europium-activated yttrium oxide phosphor by physical and chemical methods;

[0034]2) According to the wet process, 880 grams of activated carbon successfully labeled with yttrium oxide phosphor activated by europium, 50 grams of acetylene black, 70 grams of polyvinylidene fluoride and 1800 grams of N-methylpyrrolidone were put into the planetary mixer in turn, and vacuum stirred 240 minutes to form a slurry;

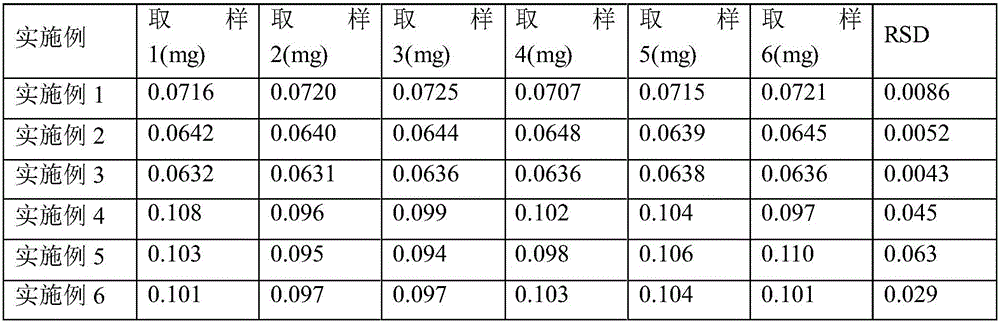

[0035] 3) Take out 0.2 grams of slurry from 6 different positions of the planetary mixer, and use a fluorescence detector to quantitatively detect the content of europium-activated yttrium oxide phosphor in the samples taken. The test results are shown in Table 1.

[0036] Coat the slurry in the planetary mixer on a 22 μm thick corroded aluminum foil to form a wet electrode, then transfer the coat...

Embodiment 2

[0038] 1) 30 grams of carbon nanotubes were weighed and placed in a stainless steel reaction kettle, and the carbon nanotubes were successfully labeled with 1 gram of terbium-activated aluminate phosphors by physical and chemical methods;

[0039] 2) According to the wet process, 30 grams of carbon nanotubes successfully labeled with terbium-activated aluminate phosphors were mixed with 900 grams of activated carbon for supercapacitors, 30 grams of poly-N-vinylacetamide, and 100 grams of styrene-butadiene. Rubber emulsion and 2050 grams of water are put into the internal mixer successively, and vacuum banburying forms slurry for 180 minutes;

[0040] 3) Take 0.2 grams of slurry from 6 different positions of the internal mixer, and use a fluorescence detector to quantitatively detect the content of terbium-activated aluminate phosphor in the sample taken. The test results are shown in Table 1.

[0041] Coat the slurry in the internal mixer on a 22 μm thick corroded aluminum foi...

Embodiment 3

[0043] 1) Weigh 66.7 grams of polytetrafluoroethylene emulsion and place it in a stainless steel reactor, and successfully label the obtained polytetrafluoroethylene emulsion with 1 gram of europium-activated barium magnesium aluminate fluorescent powder by physical and chemical methods;

[0044] 2) 66.7 grams of polytetrafluoroethylene emulsion successfully labeled with europium-activated barium magnesium aluminate fluorescent powder were mixed with 880 grams of graphene, 30 grams of carboxymethyl cellulose, 50 grams of Ketjen black and 2120 grams of water according to the wet process. Put into the kneader successively, and vacuum knead for 300 minutes to form a slurry;

[0045] 3) Take out 0.2 grams of slurry from 6 different positions of the kneader, and use a fluorescence detector to quantitatively detect the content of europium-activated barium magnesium aluminate phosphor in the sample taken. The test results are shown in Table 1.

[0046] Apply the slurry in the kneader...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com