Photosensitive resin composition and application thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition and photosensitive resin laminate, can solve problems such as problems that cannot be completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

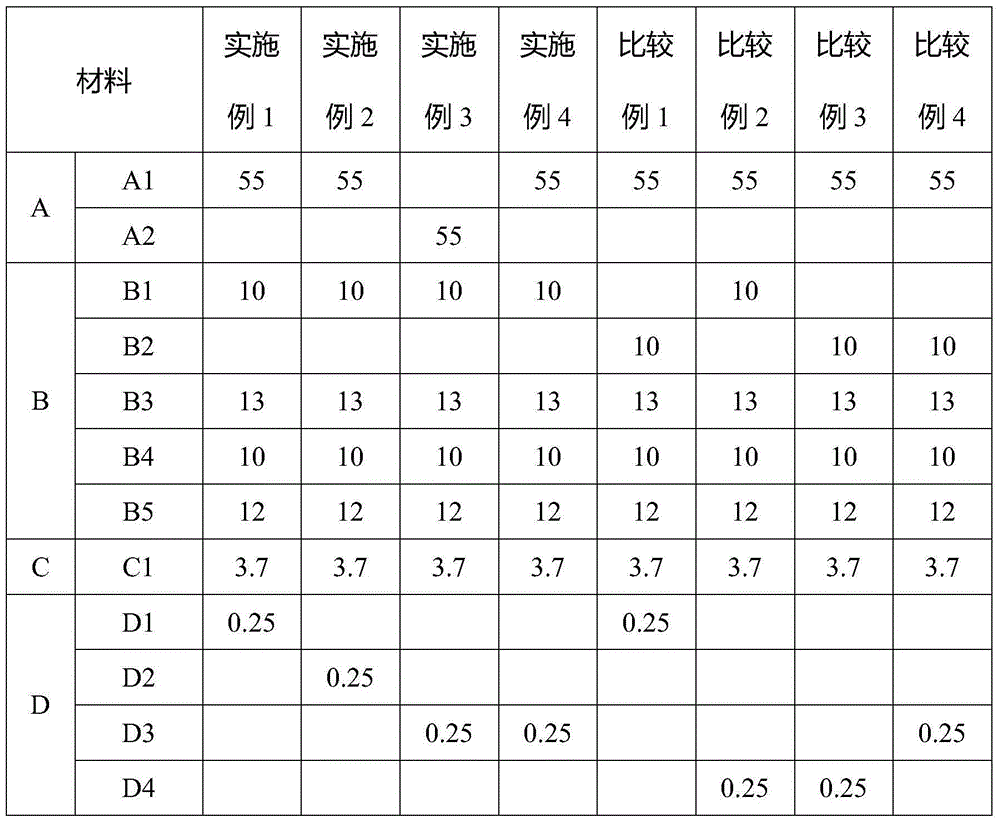

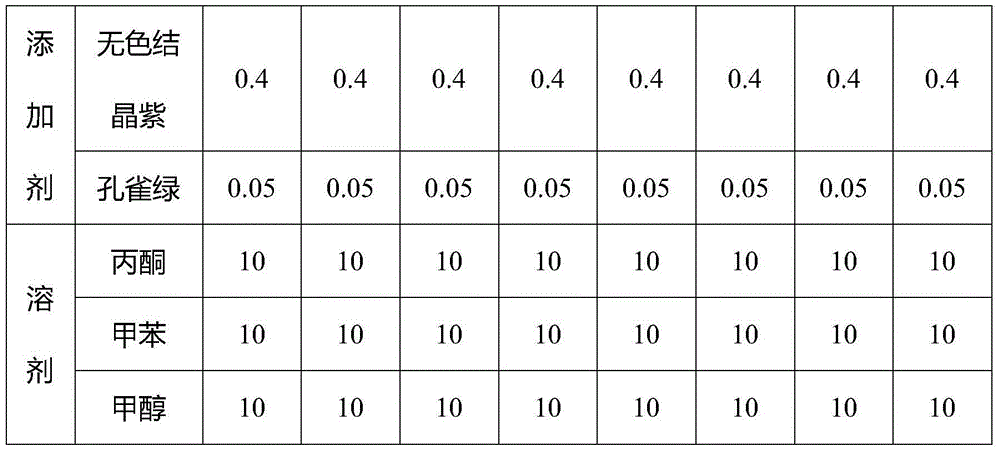

[0142] [Example 1-4, Comparative Example 1-4]

[0143]

[0144] Solution a was prepared by mixing 125 g of methacrylic acid, 275 g of methyl methacrylate, and 100 g of styrene as comonomers with 1.0 g of azobisisobutyronitrile.

[0145] 1.0 g of azobisisobutyronitrile was dissolved in a complex solution of 60 g of methyl cellosolve and 40 g of toluene to prepare a solution b.

[0146] In a flask equipped with a stirrer, a reflux condenser, a thermometer, a dropping funnel, and a nitrogen inlet tube, add methyl cellosolve and toluene in a mass ratio of 6:4 complex 400g, stir while blowing in nitrogen, and heat to 80°C.

[0147] The above-mentioned solution a was added dropwise thereto over 4 hours, and then kept at 80° C. for 2 hours while stirring. Next, the above-mentioned solution b was added dropwise to the solution in the flask over 10 minutes, and then the solution in the flask was kept at 80° C. for 3 hours while stirring the solution. Furthermore, the solution in t...

Embodiment 5-9

[0206] Examples 5-9 respectively use D5-D9 as component (D) sensitizing pigment to replace D1 in Example 1, and other conditions remain unchanged. Then, referring to the method described in Example 1, a photosensitive resin composition, a photosensitive element, and a laminate were prepared, and evaluated by the same method. The results are shown in Table 3.

[0207] table 3

[0208]

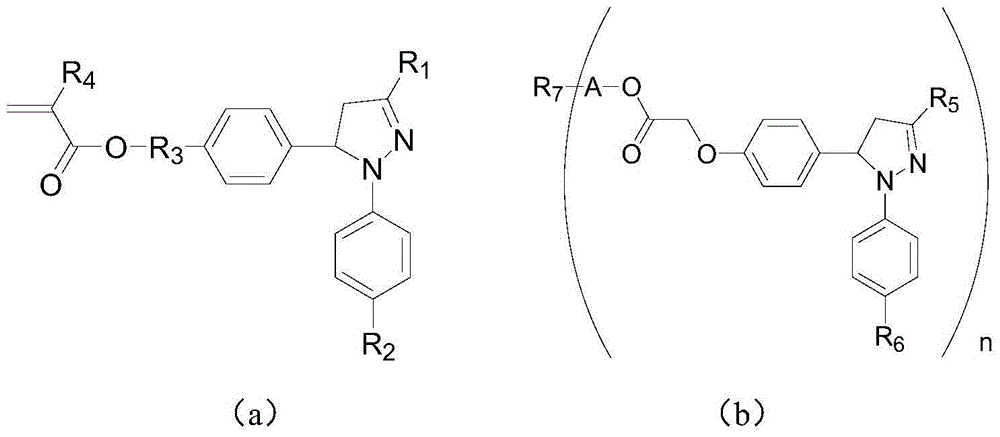

[0209] The structure of D5-D9 is as follows:

[0210]

[0211] As shown in Table 3, when the sensitizing pigment is selected from pyrazoline (especially the compound corresponding to general formula (a) or (b), the photosensitive resin composition also shows photosensitivity, reliability of cap hole , Excellent adhesion and resolution characteristics.

Embodiment 10-13

[0213] Examples 10-13 replace B1 in Example 2 with B6-B9 respectively, and other conditions remain unchanged, then refer to the method described in Example 2 to make a photosensitive resin composition, photosensitive element and laminate, and use the same method Make an evaluation. The results are shown in Table 4.

[0214] Table 4

[0215] B Example 10 Example 11 Example 12 Example 13 B6 10 B7 10 B8 10 B9 10 Photosensitivity (mJ / cm 2 )

35 35 50 50 Adhesion (μm) 15 14 15 11 Resolution (μm) 15 14 15 11 Cover hole rupture rate (%) 0 0 0 0

[0216] Table 4,

[0217] B6: compound of general formula (1), wherein n=1, A is ethyl, R 8 For methyl.

[0218] B7: compound of general formula (1), wherein n=5, A is ethyl, R 8 For methyl.

[0219] B8: compound of general formula (1), wherein n=1, A is propyl, R 8 For methyl.

[0220] B9: compound of general formula (1), wherein n=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com