ZIF-67 template method for preparing cobalt-platinum core-shell particle/porous carbon composite material and catalytic application of composite material in cathode of fuel cell

A ZIF-67, 1.ZIF-67 technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that have not yet been published in literature or patent reports, and achieve controllable morphology and simple synthesis methods , The effect of stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

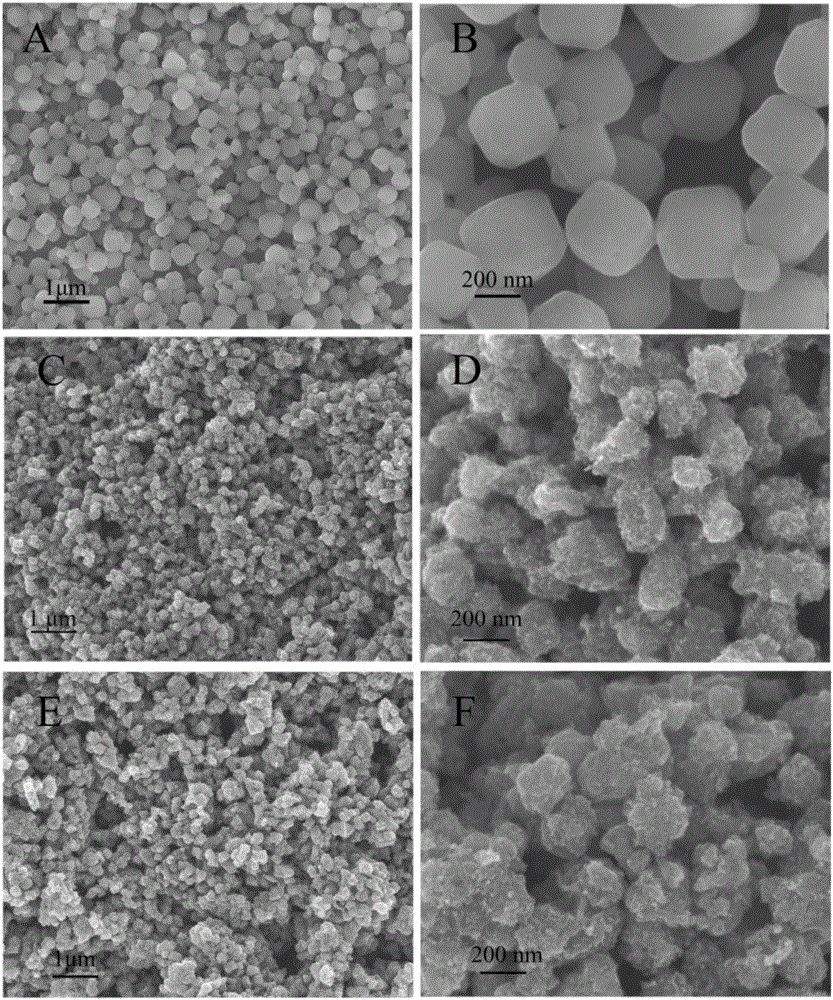

[0031] (1) According to Co 2+ :Hmim :H 2 O = 1: 58: 1100 ratio, at room temperature, the concentration of A solution is prepared to be 1.8g Co(NO 3 ) 2 • 6H 2 O was dissolved in 12 mL of water, and B solution was prepared as 22 g of 2-methylimidazole dissolved in 80 mL of deionized water; the two solutions of A and B were mixed and stirred at 800 rpm for 6 h, and the obtained blue precipitate should be in turn centrifuged, washed three times with water, washed three times with methanol, and then placed in 60 o C dried in a vacuum oven for 24 h to obtain ZIF-67 nanocrystals. figure 1 (A, B) The ZIF-67 nanocrystals shown are faceted geometries with a size of 160-400 nm.

[0032] (2) Place the ZIF-67 nanocrystals obtained above in a tube furnace protected by argon (the gas flow rate of Ar gas is about 350 sccm), and the o C / min rate heating up to 600 o C and keep warm for 2 h, and then 5 o By cooling at a cooling rate of C / min, a cobalt nanoparticle composite (Co-NC) imm...

Embodiment 2

[0042] (1) According to Co 2+ :Hmim :H 2 O = 1: 58: 1100 ratio, at room temperature, the concentration of A solution is prepared to be 1.8g Co(NO 3 ) 2 • 6H 2 O was dissolved in 12 mL of water, and B solution was prepared as 22 g of 2-methylimidazole dissolved in 80 mL of deionized water; the two solutions of A and B were mixed and stirred at 800 rpm for 6 h, and the obtained blue precipitate should be in turn centrifuged, washed three times with water, washed with methanol, and placed at 60 o C dried in a vacuum oven for 24 h to obtain ZIF-67 nanocrystals. figure 1 (A, B) The ZIF-67 nanocrystals shown are faceted geometries with a size of 160-400 nm.

[0043] (2) Place the ZIF-67 nanocrystals obtained above in a tube furnace protected by argon (the flow rate of Ar gas is about 350 sccm), and the o C / min rate heating up to 600 o C and keep warm for 2 h, and then 5 o By cooling at a cooling rate of C / min, a cobalt nanoparticle composite (Co-NC) immobilized by nitrogen...

Embodiment 3

[0049] (1) According to Co 2+ :Hmim :H 2 O = 1: 58: 1100 ratio, at room temperature, the concentration of A solution is prepared to be 1.8g Co(NO 3 ) 2 • 6H 2 O was dissolved in 12 mL of water, and B solution was prepared as 22 g of 2-methylimidazole dissolved in 80 mL of deionized water; the two solutions of A and B were mixed and stirred at 800 rpm for 6 h, and the obtained blue precipitate should be in turn centrifuged, washed three times with water, washed three times with methanol, and then placed in 60 o C dried in a vacuum oven for 24 h to obtain ZIF-67 nanocrystals. figure 1 (A, B) The ZIF-67 nanocrystals shown are faceted geometries with a size of 160-400 nm.

[0050](2) Place the ZIF-67 nanocrystals obtained above in a tube furnace protected by argon (the flow rate of Ar gas is about 350 sccm), and the o C / min rate heating up to 600 o C and keep warm for 2 h, and then 5 o By cooling at a cooling rate of C / min, a cobalt nanoparticle composite (Co-NC) immobil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com