Method for separating and recycling iridium from iridium-containing waste catalyst

A waste catalyst, separation and recovery technology, applied in the field of recovery and separation of platinum group metal iridium, can solve the problems of large reagent consumption, low recovery rate of iridium, long process, etc., and achieve the effect of high recovery rate, lower production cost, and shortened cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

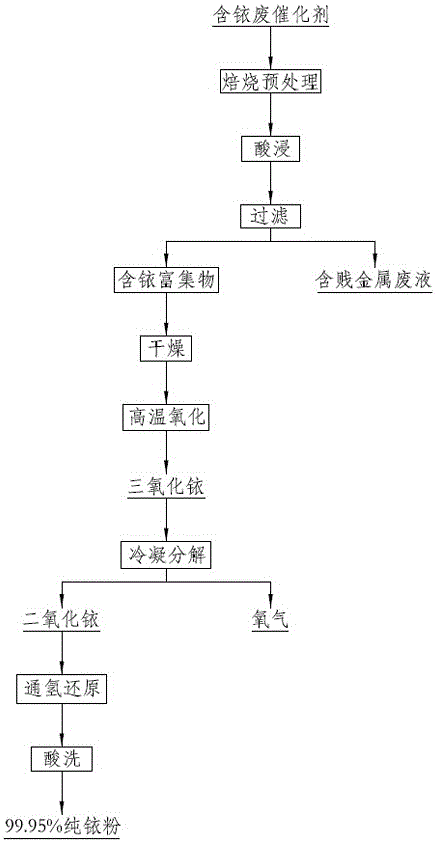

[0022] A method for separating and recovering iridium from iridium-containing spent catalysts, carried out according to the following steps:

[0023] (1) Roasting pretreatment: take 1000g of spent catalyst with an iridium content of 25.6%, and roast it at 450°C for 4 hours to remove carbon and other organic matter on the surface of the spent catalyst;

[0024] (2) Acid leaching: Slowly add 4L 30% HCl and 25% H to the roasted material 2 SO 4 The mixed acid was reacted for 2.5 hours to dissolve and remove the base metal impurities, and then filtered, and the insoluble residue was dried at 200°C for 24 hours to obtain the enrichment of iridium;

[0025] (3) High-temperature oxidation: put the enriched iridium into the tube furnace to raise the temperature to 1050°C, then pass in oxygen, and irradiate the oxygen in the tube furnace with ultraviolet rays for 6 hours, and collect the generated volatilization at the other end of the tube furnace Sexual substance IrO 3 , to separat...

Embodiment 2

[0030] A method for separating and recovering iridium from iridium-containing spent catalysts, carried out according to the following steps:

[0031] (1) Roasting pretreatment: Take 1000g of spent catalyst with an iridium content of 30.28%, and roast it at a temperature of 500°C for 5 hours to remove carbon and other organic matter on the surface of the spent catalyst;

[0032] (2) Acid leaching: Slowly add 4L 30% HCl and 25% H to the roasted material 2 SO 4 The mixed acid was reacted for 4 hours to dissolve and remove the base metal impurities, and then filtered, and the insoluble residue was dried at 200°C for 24 hours to obtain the enrichment of iridium;

[0033] (3) High-temperature oxidation: Put the enriched iridium into the tube furnace to heat up to 1100°C, then pass in oxygen, and irradiate the oxygen in the tube furnace with ultraviolet light to react for 7 hours, and collect the generated volatilization at the other end of the tube furnace Sexual substance IrO 3 ...

Embodiment 3

[0038] A method for separating and recovering iridium from iridium-containing spent catalysts, carried out according to the following steps:

[0039] (1) Roasting pretreatment: take 1,000 g of spent catalyst with an iridium content of 30.28%, and roast it at 600°C for 6 hours to remove carbon and other organic matter on the surface of the spent catalyst;

[0040] (2) Acid leaching: Slowly add 4L 30% HCl and 25% H to the roasted material 2 SO 4 The mixed acid was reacted for 4 hours to dissolve and remove the base metal impurities, and then filtered, and the insoluble residue was dried at 200°C for 24 hours to obtain the enrichment of iridium;

[0041] (3) High-temperature oxidation: Put the enriched iridium into the tube furnace to raise the temperature to 1150°C, then pass in oxygen, and irradiate the oxygen in the tube furnace with ultraviolet rays for 6 hours, and collect the generated volatilization at the other end of the tube furnace Sexual substance IrO 3 , to separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com