Preparation process of ferrite and neodymium iron boron (NdFeB) composite bonded magnet

A bonded magnet and preparation technology, which is applied in the field of magnetic material manufacturing, can solve the problems of poor product performance consistency, cracking, low strength, etc., and achieve the effect of good consistency and magnetic performance, simple process steps, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

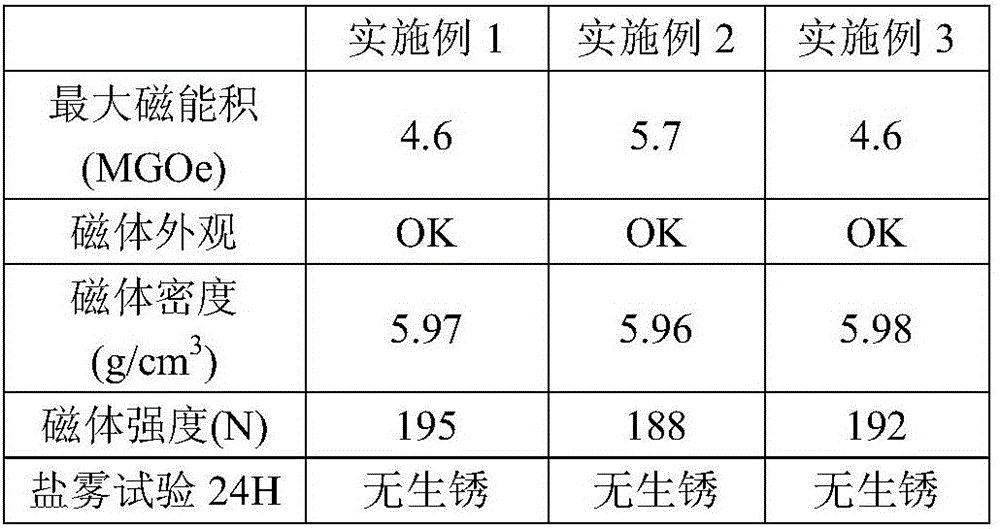

Examples

Embodiment 1

[0025] (1) After ball milling and drying strontium red ferrite, mix it evenly with NdFeB magnetic powder to obtain a mixture. The mass ratio of strontium red ferrite material to NdFeB magnetic powder is controlled at 1:9, strontium red iron The oxygen body is ball milled to a particle size of 25 μm, and the particle size of the NdFeB magnetic powder is 25 μm;

[0026] (2) After dissolving W-6C epoxy resin in acetone, add the mixture and stir evenly, and dry it stably at 50°C. The mass ratio of W-6C epoxy resin to mixture is 2:100;

[0027] (3) Add the dried material to the crushing and vibrating screen machine and crush it through a 100-mesh sieve. After being pressed into a magnetic ring, use epoxy resin paint EP-703 to paint on the surface. The thickness of the paint is 0.03mm, and it is dried at 150°C The product is obtained in 30-min.

Embodiment 2

[0029] (1) After ball milling and drying strontium red ferrite, mix it evenly with NdFeB magnetic powder to obtain a mixture. The mass ratio of strontium red ferrite material to NdFeB magnetic powder is controlled at 1:4, strontium red iron The oxygen body is ball milled to a particle size of 27 μm, and the particle size of NdFeB magnetic powder is 30 μm;

[0030] (2) After dissolving W-6C epoxy resin in acetone, add the mixture and stir evenly, and dry it stably at 55°C. The mass ratio of W-6C epoxy resin to mixture is 2.5:100;

[0031] (3) Add the dried material to the crushing and vibrating screen machine and crush it through a 100-mesh sieve. After being pressed into a magnetic ring, use epoxy resin paint EP-703 to spray paint on the surface. The product is ready in 40 minutes.

Embodiment 3

[0033] (1) After ball milling and drying strontium red ferrite, mix it evenly with NdFeB magnetic powder to obtain a mixture. The mass ratio of strontium red ferrite material to NdFeB magnetic powder is controlled at 1:1, strontium red iron The oxygen body is ball milled to a particle size of 35 μm, and the particle size of the NdFeB magnetic powder is 35 μm;

[0034] (2) After dissolving W-6C epoxy resin in acetone, add the mixture and stir evenly, and dry it stably at 60°C. The mass ratio of W-6C epoxy resin to mixture is 3:100;

[0035] (3) Add the dried material to the crushing and vibrating screen machine and crush it through a 100-mesh sieve, press it into a magnetic ring, and then spray paint on the surface with epoxy resin paint EP-703. The product was obtained in 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com