Three-dimensional graphene modification-based plastic composite material and preparation thereof

A graphene modification and composite material technology, applied in the field of materials, can solve the problems of insufficient addition of conductive fillers, inability to meet the processing needs of high-end electrical equipment, and reduced mechanical properties, achieving low production costs and realizing large-scale industrial production. , the effect of no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

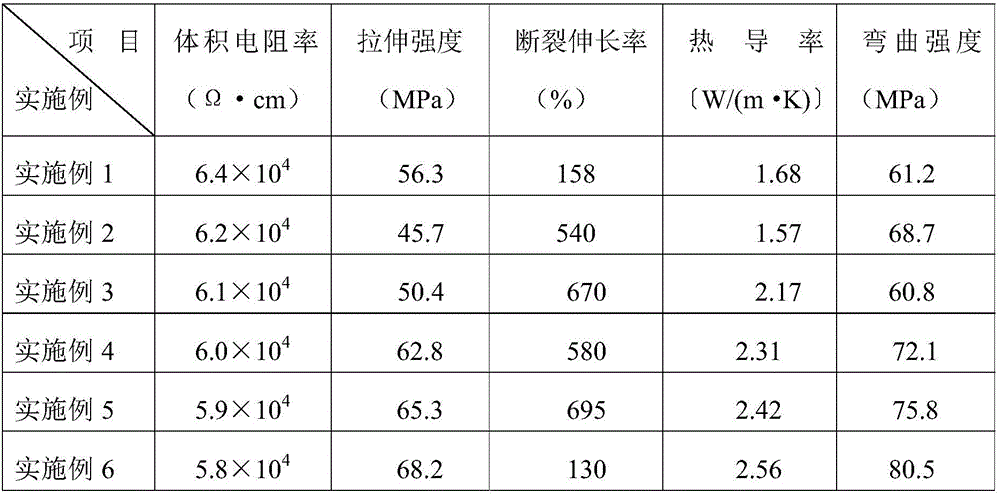

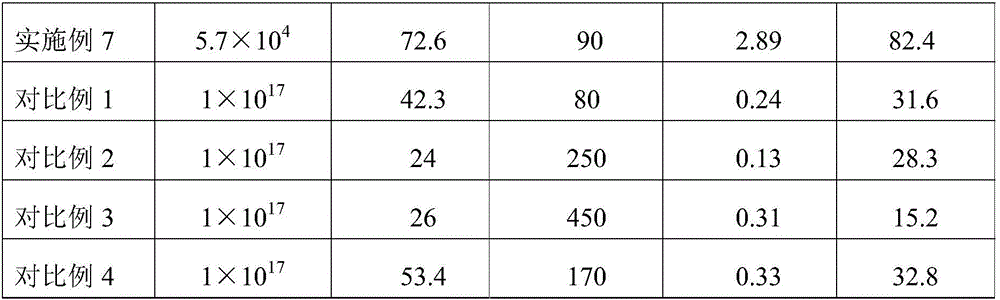

Examples

Embodiment 1

[0023] Step 1) prepare graphene oxide by improved Hummers method, be divided into pre-oxidation, oxidation and exfoliation.

[0024] Pre-oxidation: the mass parts are 1 part of natural graphite, 3 parts of concentrated sulfuric acid, 0.5 part of K 2 S 2 o 8 and P 2 o 5 Mix and heat to 80°C, react for 6 hours, wash with ultrapure water until neutral to obtain pre-oxidized graphite.

[0025] Oxidation: At 0°C, mix pre-oxidized graphite with 6 parts of concentrated sulfuric acid, and gradually add 1 part of KMnO under stirring 4 , during which the temperature of the mixture is controlled below 20°C. The temperature of the mixture was raised to 35°C, and after stirring for 2 hours, 20 parts of ultrapure water was added, stirring was continued for 15 minutes, and finally 40 parts of ultrapure water was added to terminate the reaction. Next, add 2 parts of 30% H 2 o 2 , the mixture was centrifuged with 10% HCl to remove excess metal ions. The obtained precipitate was repeat...

Embodiment 2

[0030] Step 1) prepare graphene oxide by improved Hummers method, be divided into pre-oxidation, oxidation and exfoliation.

[0031] Pre-oxidation: the mass parts are 1 part of natural graphite, 4 parts of concentrated sulfuric acid, 0.6 part of K 2 S 2 o 8 and P 2 o 5 Mix and heat to 80°C, react for 6 hours, wash with ultrapure water until neutral to obtain pre-oxidized graphite.

[0032] Oxidation: At 0°C, mix pre-oxidized graphite with 7 parts of concentrated sulfuric acid, and gradually add 1.5 parts of KMnO under stirring 4 , during which the temperature of the mixture is controlled below 20°C. The temperature of the mixture was raised to 35°C, and after stirring for 2 hours, 25 parts of ultrapure water was added, stirring was continued for 15 minutes, and finally 50 parts of ultrapure water was added to terminate the reaction. Next, add 2 parts of 30% H 2 o 2 , the mixture was centrifuged with 10% HCl to remove excess metal ions. The obtained precipitate was rep...

Embodiment 3

[0037] Step 1) prepare graphene oxide by improved Hummers method, be divided into pre-oxidation, oxidation and exfoliation.

[0038] Pre-oxidation: the mass parts are 1 part of natural graphite, 5 parts of concentrated sulfuric acid, 0.7 part of K 2 S 2 o 8 and P2 o 5 Mix and heat to 80°C, react for 6 hours, wash with ultrapure water until neutral to obtain pre-oxidized graphite.

[0039] Oxidation: At 0°C, mix graphite oxide with 8 parts of concentrated sulfuric acid, and gradually add 2 parts of KMnO under stirring 4 , during which the temperature of the mixture is controlled below 20°C. The temperature of the mixture was raised to 35°C, and after stirring for 2 hours, 30 parts of ultrapure water was added, stirring was continued for 15 minutes, and finally 60 parts of ultrapure water was added to terminate the reaction. Next, add 2 parts of 30% H 2 o 2 , the mixture was centrifuged with 10% HCl to remove excess metal ions. The obtained precipitate was repeatedly cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com