Bagasse biodegradable plastic and preparation method thereof

A technology of biodegradable plastics and degradable plastics, applied in the field of bagasse biodegradable plastics and its preparation, can solve the problems of non-thermoplasticity, poor water resistance, difficult molding and processing, etc., and achieve the effect of enhancing strength and improving interface affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

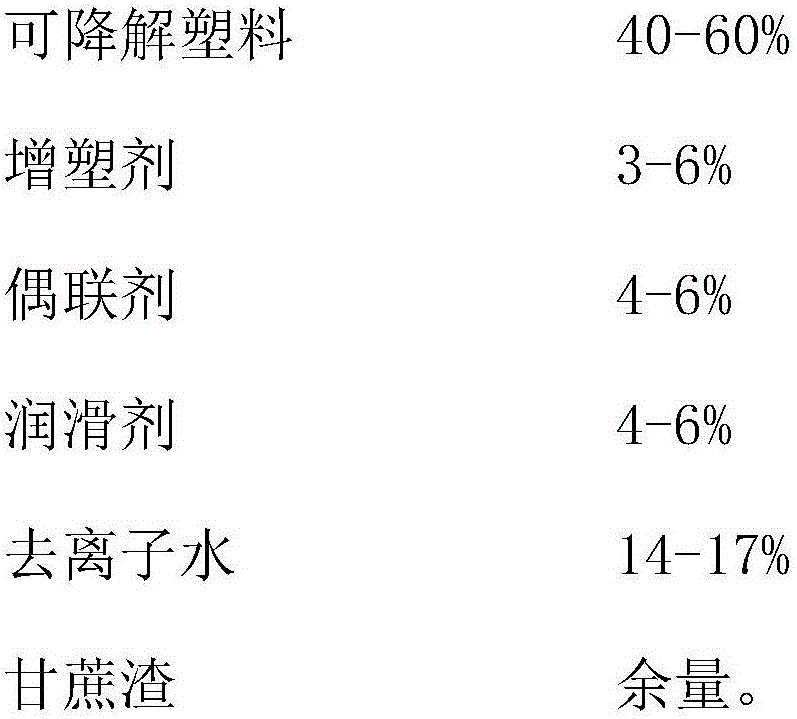

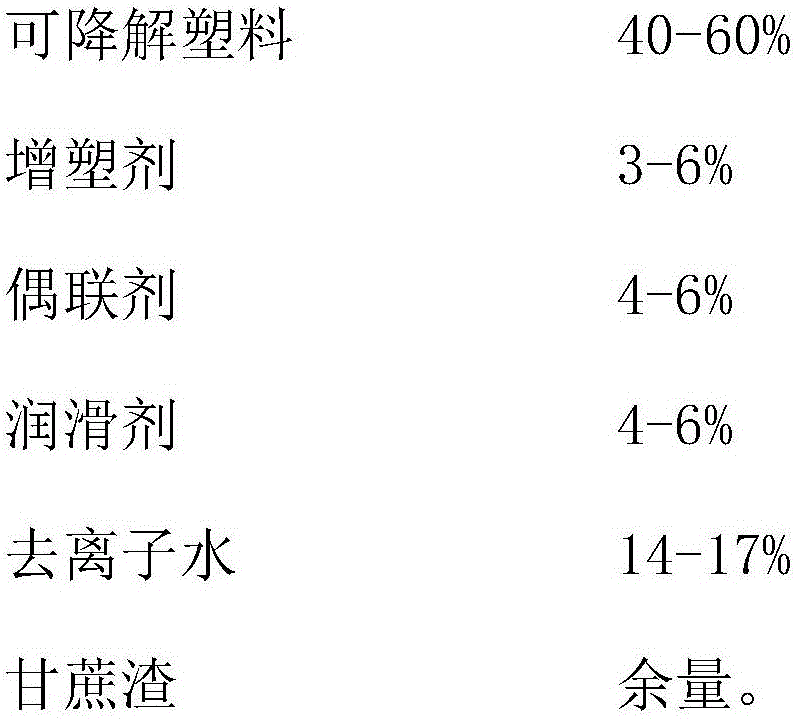

[0028] A kind of bagasse biodegradable plastics, its preparation method, comprises the following steps:

[0029] 1) Pulverize the bagasse with a pulverizer, then boil it in boiling water for 40 minutes according to the material-to-liquid ratio of 1:20, wash it with distilled water, and dry it at 95°C for later use to obtain the bagasse powder after removing impurities and heat treatment, and keep it sealed in in the dryer;

[0030] 2) Take out 150g of the bagasse powder obtained in step 1), add 200g of polyεcaprolactone, 25g of monoglyceride, 25g of aluminate, and 25g of paraffin oil, mix evenly, and then stir at a stirring speed of 400r / min. Add 75g of deionized water, stir evenly, seal and place for 6h, make the material fully mix and swell, and obtain the mixed material;

[0031] 3) The mixed material in step 2) is heated to 180° C., kneaded and hot-pressed, finally cooled to 50° C., and pressed into a plastic sheet with a thickness of 2 mm.

Embodiment 2

[0033] A kind of bagasse biodegradable plastics, its preparation method, comprises the following steps:

[0034] 1) Pulverize the bagasse with a pulverizer, then boil it in boiling water for 30 minutes according to the material-to-liquid ratio of 1:15, wash it with distilled water, dry it at 95°C for later use, and obtain the bagasse powder after removing impurities and heat treatment, and store it in a sealed container. in the dryer;

[0035] 2) Take out 150g of the bagasse powder obtained in step 1), add 200g polybutylene succinate, 10g synthetic vegetable ester, 10g monoglyceride, 25g titanate, 25g calcium stearate and mix evenly, then Stirring, the stirring speed is 600r / min, while adding 80g of deionized water, after stirring evenly, seal and place for 6h, so that the materials are fully mixed and swollen, and the mixed materials are obtained;

[0036] 3) The mixed material in step 2) is heated to 180° C., kneaded and hot-pressed, finally cooled to 50° C., and pressed in...

Embodiment 3

[0038] A kind of bagasse biodegradable plastics, its preparation method, comprises the following steps:

[0039] 1) Pulverize the bagasse with a pulverizer, then boil it in boiling water for 40 minutes according to the material-to-liquid ratio of 1:25, then wash it with distilled water, dry it at 95°C for later use, and obtain the bagasse powder after removing impurities and heat treatment, and store it in a sealed container. in the dryer;

[0040] 2) Take out 100g of the bagasse powder obtained in step 1), add 600g poly-β-hydroxybutyric acid, 30g acetyl tri-n-butyl citrate, 60g silane coupling agent, 29g glycerin, 21g paraffin oil and mix well, then Stirring, the stirring speed is 600r / min, while adding 160g of deionized water, after stirring evenly, seal and place for 6h, so that the materials are fully mixed and swelled, and the mixed materials are obtained;

[0041] 3) The mixed material in step 2) is heated to 180° C., kneaded and hot-pressed, finally cooled to 50° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com