Double-channel liquid metal magnetic fluid power generator

A magnetic fluid generator and magnetic fluid power generation technology, applied in electrical components, electromechanical devices and other directions, can solve the problems of large amount of gallium alloy and high production cost of generators, and achieve the effect of reducing the number of use, compact structure and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

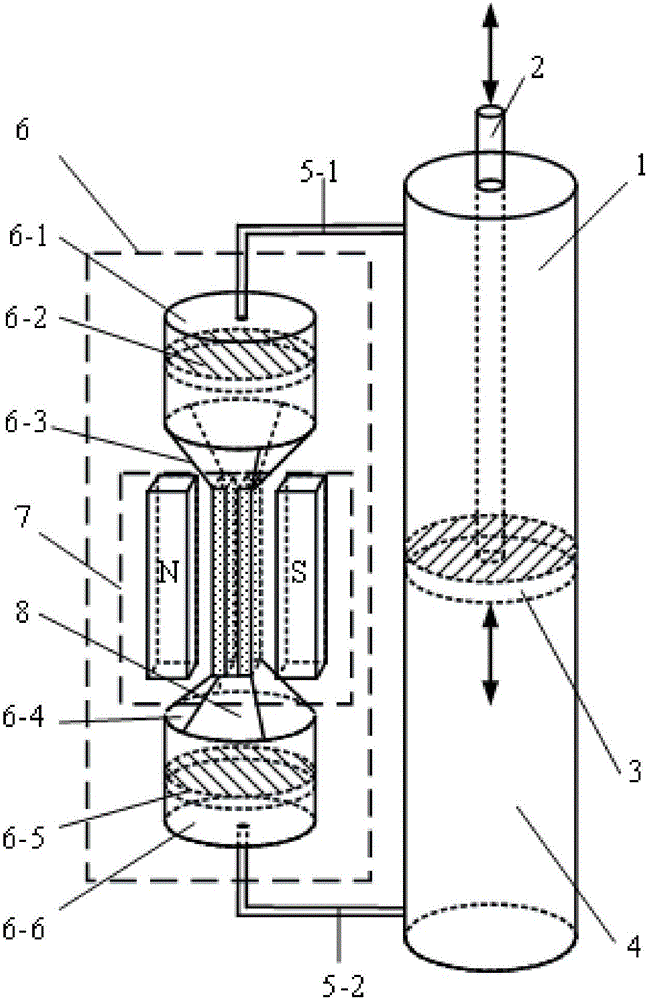

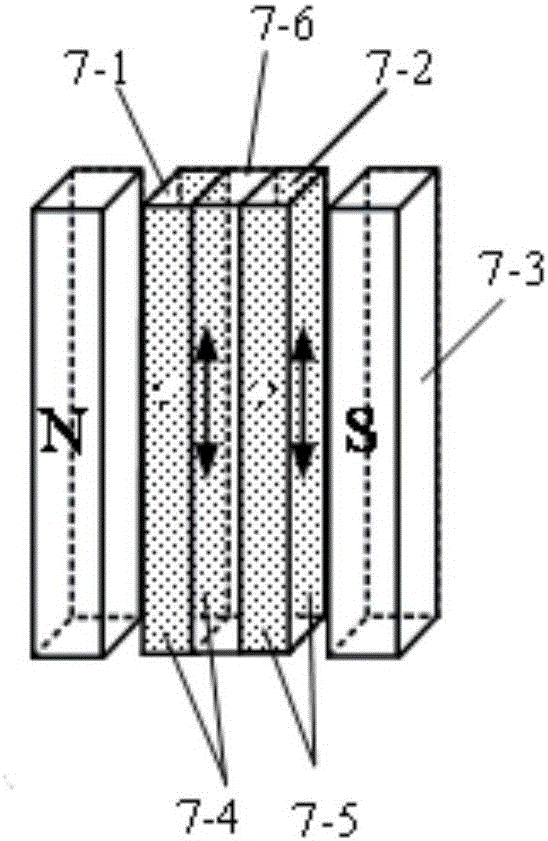

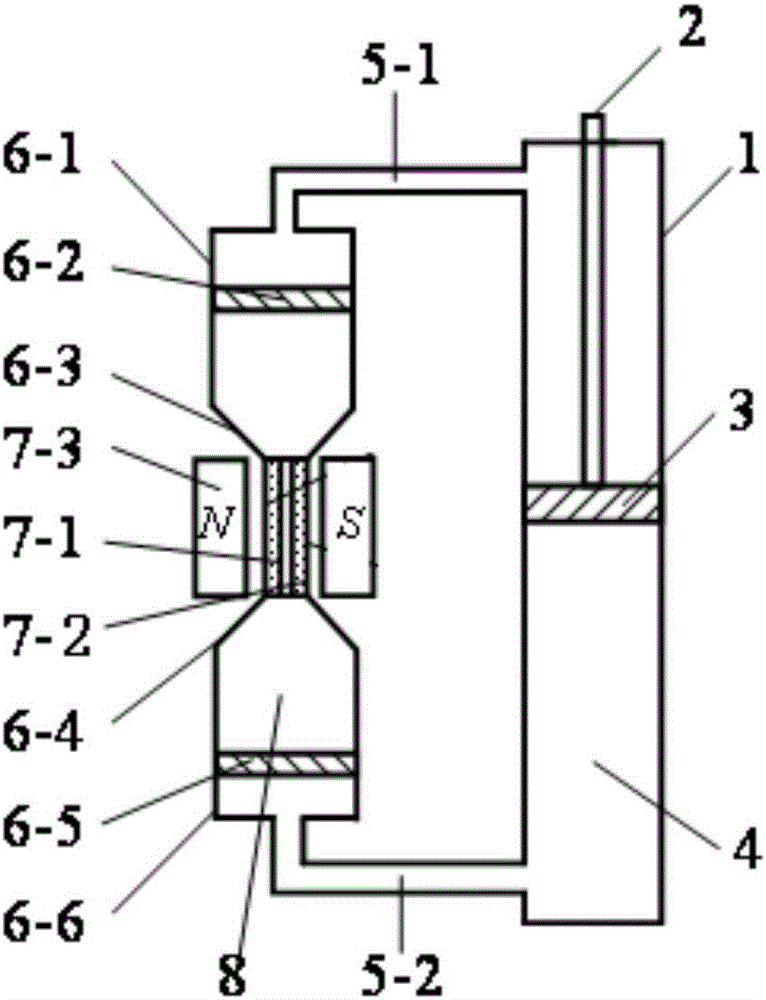

[0027] see Figure 1 to Figure 3 As shown, in this embodiment, a dual-channel liquid metal magnetic fluid generator includes a main hydraulic cylinder 1, a main piston rod 2, a main piston 3, hydraulic oil 4, an upper connecting pipe 5-1, and a lower connecting pipe 5-2 Composed of a set of power generation unit 6, the power generation unit 6 includes an upper piston cylinder 6-1, an upper piston 6-2, an upper transition section 6-3, a lower transition section 6-4, a lower piston 6-5, a lower piston cylinder 6-6 and an effective magnetic fluid power generation section 7, the effective magnetic fluid power generation section 7 includes a first magnetic fluid power generation channel 7-1, a second magnetic fluid power generation channel 7-2, a magnet 7-3, and a pair of first plate electrodes 7-4. The second plate electrode pair 7-5 and the insulating plate 7-6.

[0028] The first magnetic fluid power generation channel 7-1 and the second magnetic fluid power generation channel ...

Embodiment 2

[0038] see Figure 4 As shown, the dual-channel liquid metal magnetic fluid generator of this embodiment and the first embodiment has an equivalent power generation effect. In the form of the unit, the two generating units are symmetrically arranged, which include the main hydraulic cylinder 1, the main piston rod 2, the main piston 3, the hydraulic oil 4, the first upper connecting pipe 5-1-1, and the first lower connecting pipe 5-2 -1. The second upper connection pipe 5-1-2, the second lower connection pipe 5-2-2, the first power generation unit and the first power generation unit, the two ends of the first power generation unit and the second power generation unit are respectively It is symmetrically connected to the main pipe through the first upper connecting pipe 5-1-1, the first lower connecting pipe 5-2-1, the second upper connecting pipe 5-1-2 and the second lower connecting pipe 5-2-2. on hydraulic cylinder 1.

[0039] The first power generation unit includes a fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com