A grinding method of Dexibuprofen and the preparation method of its suspension

A grinding method and technology of grinding materials, which are applied in liquid transportation, emulsion transportation, antipyretic drugs, etc., to achieve good application prospects and industrial production potential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

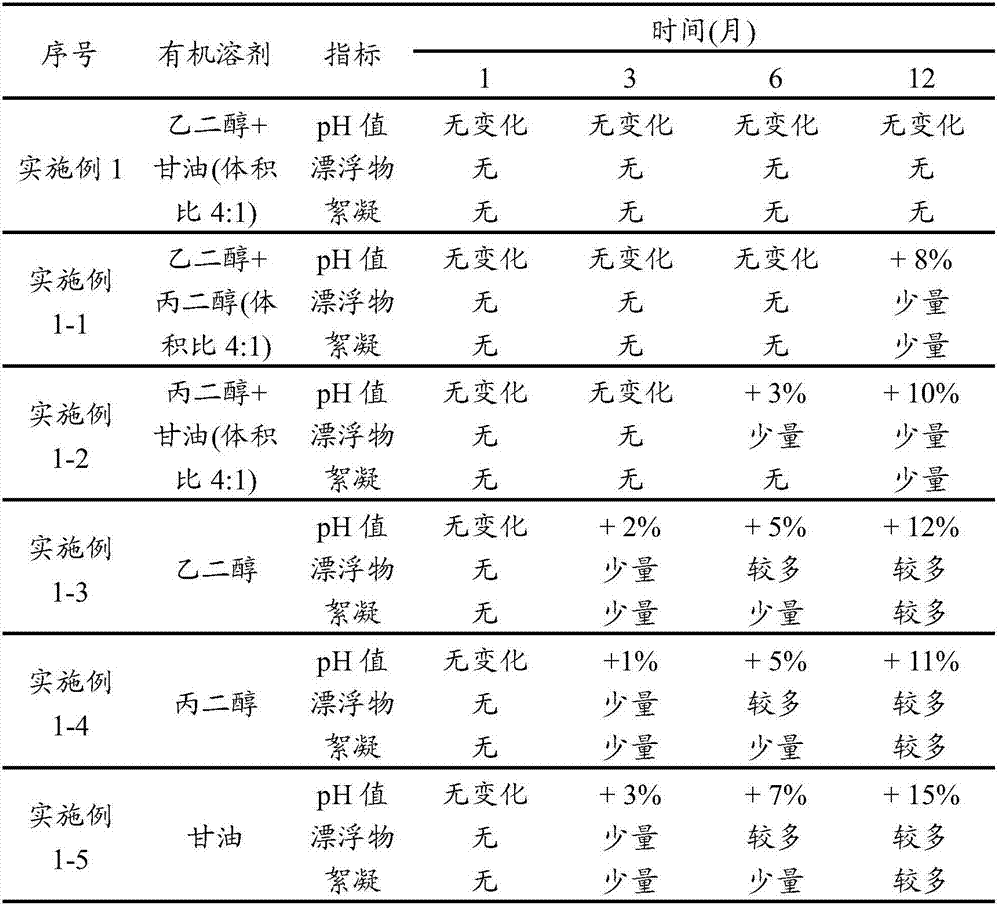

[0045] Embodiment 1: the investigation of organic solvent kind

[0046] S1: adding Dexibuprofen to the mixed solvent to obtain a mixture of Dexibuprofen, specifically:

[0047] 1.5 parts by mass of Dexibuprofen are added to a mixed solvent of 3 parts by mass of organic solvent (see Table 1 below for specific composition) and 1 part by mass of water, and fully stirred to obtain a mixture of Dexibuprofen;

[0048] S2: prepare acidic sol, specifically:

[0049] In parts by mass, 3 parts of agar, 1 part of sodium citrate, 1.1 parts of sodium benzoate, 12 parts of sucrose and 0.25 parts of mannitol were added to 100 parts of double distilled water, and kept stirring until the agar swelled completely, and the mixture was adjusted. The pH value is 5.0, and an acidic sol is obtained;

[0050] S3: After mixing the dextrobuprofen mixture obtained in step S1 with the acid sol obtained in step S2, grind to obtain a dextrobuprofen grind, specifically:

[0051] S3-1: Weighing 100 parts b...

Embodiment 2

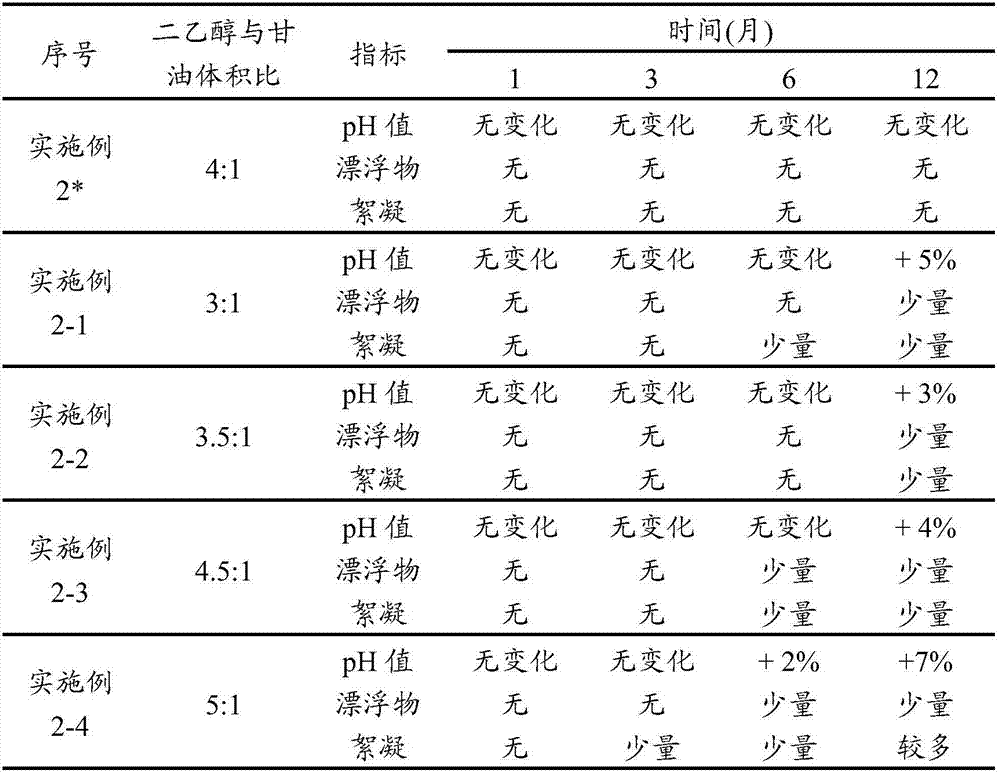

[0060] Embodiment 2: the investigation of organic solvent composition

[0061] S1: adding Dexibuprofen to the mixed solvent to obtain a mixture of Dexibuprofen, specifically:

[0062] 1.5 parts by mass of dextroibuprofen are added to 3 parts by mass of organic solvent (for the mixture of ethylene glycol and glycerin, the volume ratio is shown in the following table 2) and in the mixed solvent of 1 part by mass of water, fully stirred to obtain dextro ibuprofen ibuprofen mixture;

[0063] Other steps S2, S3 and the preparation of the subsequent suspension are the same as in Example 1.

[0064] The obtained Dexibuprofen suspension was placed for a period of time, and the changes in its appearance and various indicators were observed to investigate the influence of different organic solvent compositions on the stability of the product. The results are shown in Table 2 below.

[0065] Table 2

[0066]

[0067] Among them, "Example 2" indicated by "*" is actually Example 1. ...

Embodiment 3

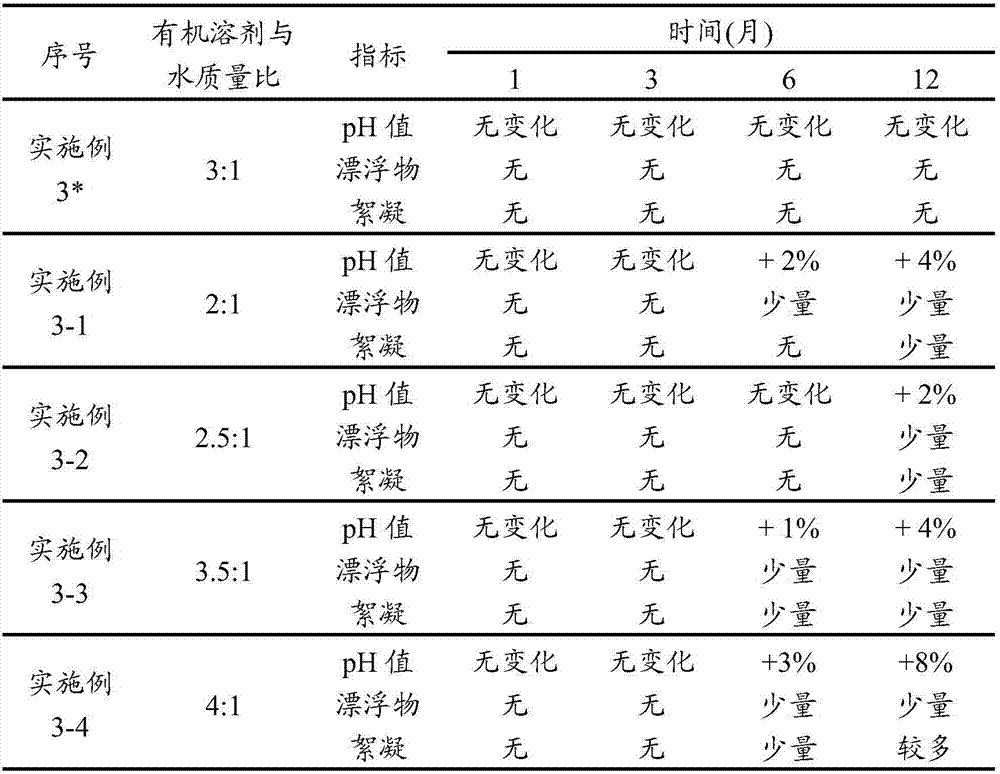

[0069] Embodiment 3: the investigation of organic solvent and water consumption ratio

[0070] S1: adding Dexibuprofen to the mixed solvent to obtain a mixture of Dexibuprofen, specifically:

[0071] 1.5 parts by mass of Dexibuprofen are added to the mixed solvent of 3 parts by mass of organic solvent (a mixture of ethylene glycol and glycerol in a volume ratio of 4:1) and water (the mass ratio of organic solvent to water is shown in Table 3 below) In, fully stir, thus obtain the Dexibuprofen mixture;

[0072] Other steps S2, S3 and the preparation of the subsequent suspension are the same as in Example 1.

[0073] The obtained Dexibuprofen suspension was placed for a period of time, and its appearance and changes in various indicators were observed to investigate the influence of different organic solvent compositions on the stability of the product. The results are shown in Table 3 below.

[0074] table 3

[0075]

[0076] Among them, "Example 3" indicated by "*" is ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com