A biocl/al2o3 heterojunction material with photocatalytic activity and its preparation method

A photocatalytic activity, heterojunction technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of limited contact area, limited transfer speed of photogenerated carriers, etc. The preparation process is simple, it is beneficial to the transfer of electrons and catalytic activity, and the effect of broadening the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Prepare pure BiOCl according to the following steps

[0020] ① Mix 0.005 mol of bismuth nitrate and 0.005 mol of diethylamine hydrochloride, heat to melt to form ionic liquid;

[0021] ② Heat the ionic liquid described in step ① in a tube furnace at a heating rate of 10 ℃ / min until the ionic liquid burns, and the combustion produces a large amount of smoke and releases a large amount of heat;

[0022] ③Collect the solid produced after the complete combustion in step ②, cool and grind to obtain powder.

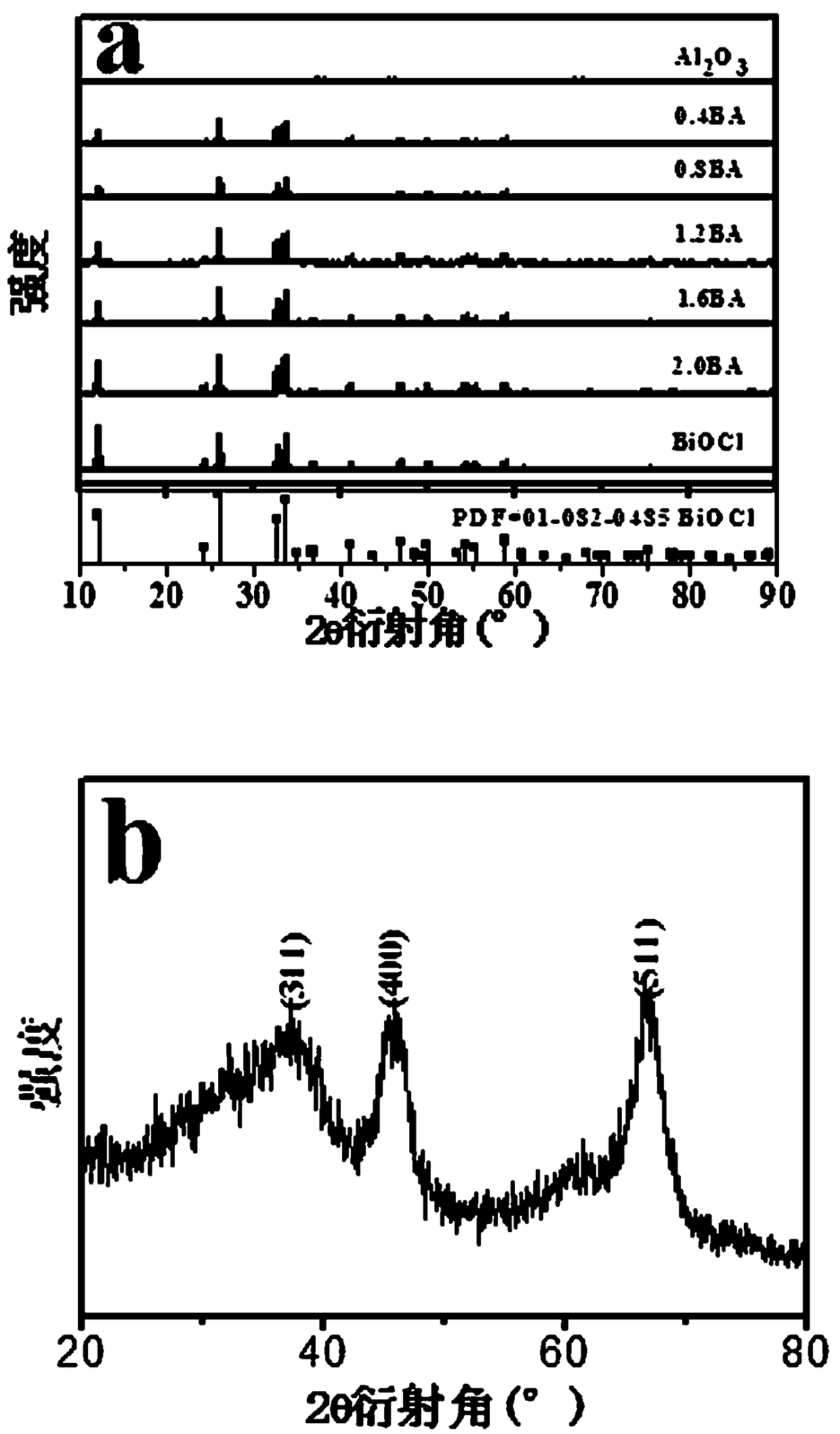

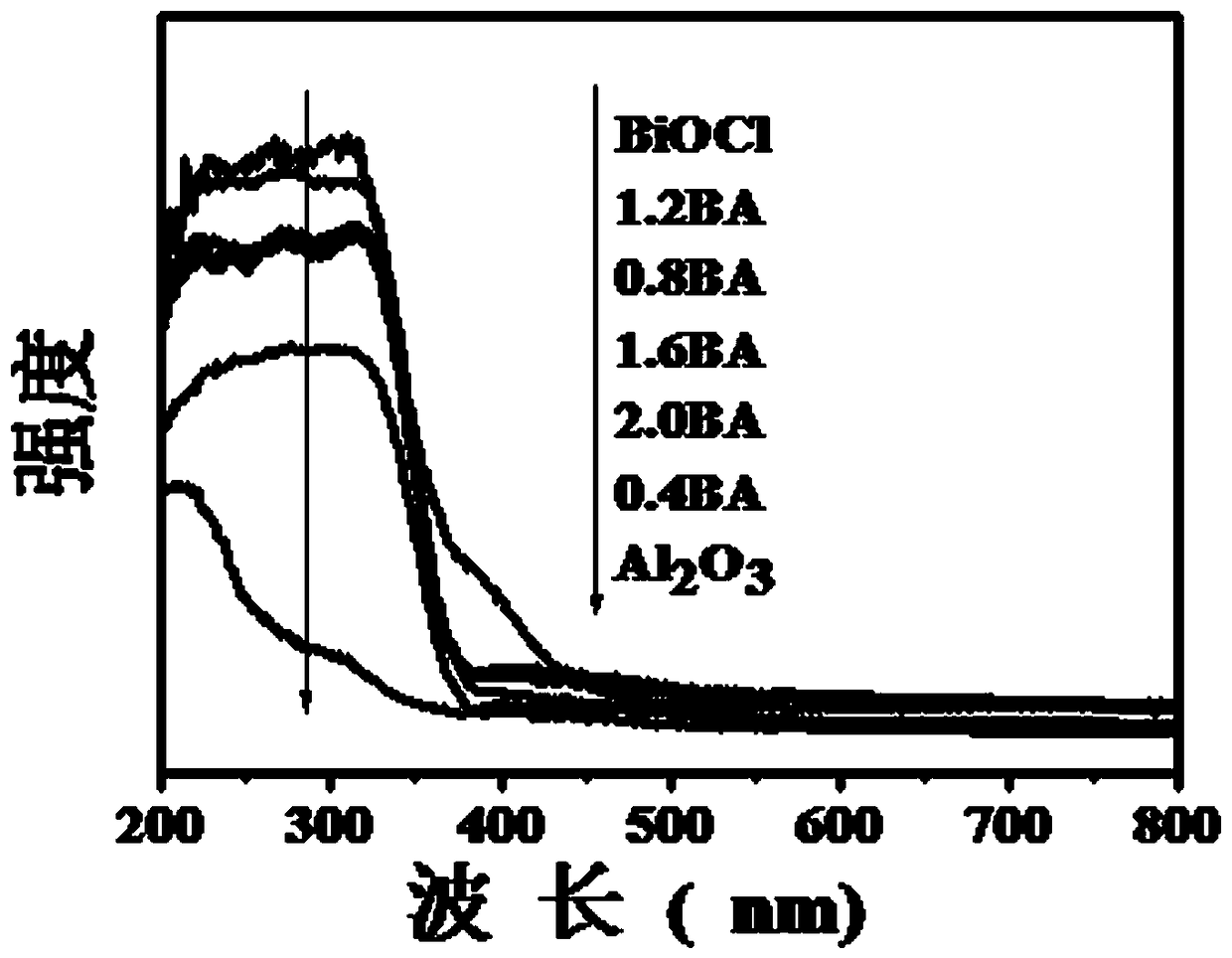

[0023] The above powders were tested by XRD and UV-Vis DRS respectively, and the test patterns were as follows: figure 1 and figure 2 shown. figure 1 aXRD results show that the powder is pure BiOCl; figure 2 It can be seen from the figure that the pure BiOCl prepared in this example has absorption in the ultraviolet and visible light regions, and the absorption in the visible light region may come from the surface oxygen vacancies. SEM pictures such as...

Embodiment 2

[0025] Example 2 Prepare pure Al according to the following steps 2 o 3

[0026] ① Mix 0.010 mol aluminum nitrate and 0.010 mol diethylamine hydrochloride and heat until ionic liquid is formed;

[0027] ②Heat the above-mentioned ionic liquid in a resistance furnace at a heating rate of 50 ℃ / min until the ionic liquid burns, and the combustion produces a large amount of smoke and heat;

[0028] ③Collect the solid produced after the complete combustion in step ②, cool and grind to obtain a white powder.

[0029] Carry out XRD and UV-Vis DRS test to above-mentioned white powder, its pattern see respectively figure 1 and figure 2 . Depend on figure 1 a can see Al 2 o 3 There are no obvious characteristic peaks, in order to find Al 2 o 3 The crystalline phase, the enlarged Al 2 o 3 XRD as figure 1 As shown in b, there are mainly three diffraction peaks at 37.4°, 45.5° and 66.9°, corresponding to cubic γ-Al 2 o 3 (311), (400) and (440) diffractive phases of (JCPDS ...

Embodiment 3

[0031] Example 3 Prepare BiOCl / Al according to the following steps 2 o 3 Heterojunction

[0032] ① Mix and heat 0.002 mol bismuth nitrate, 0.010 mol aluminum nitrate and 0.010 mol diethylamine hydrochloride until ionic liquid is formed;

[0033] ②Heat in the tube furnace at a heating rate of 5 ℃ / min until the ionic liquid burns, and the combustion produces a lot of smoke and heat;

[0034] ③ Collect the solids produced after complete combustion, cool and grind to obtain BiOCl / Al 2 o 3 Heterojunction powder, the sample is named 0.4BA. Its XRD and UV-Vis DRS patterns refer to figure 1 a and figure 2 .

[0035] According to the method of Example 1, the visible light catalytic activity test was carried out, and the results showed that the degradation rate of phenol was 25.4% after irradiating for 240 min, as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com