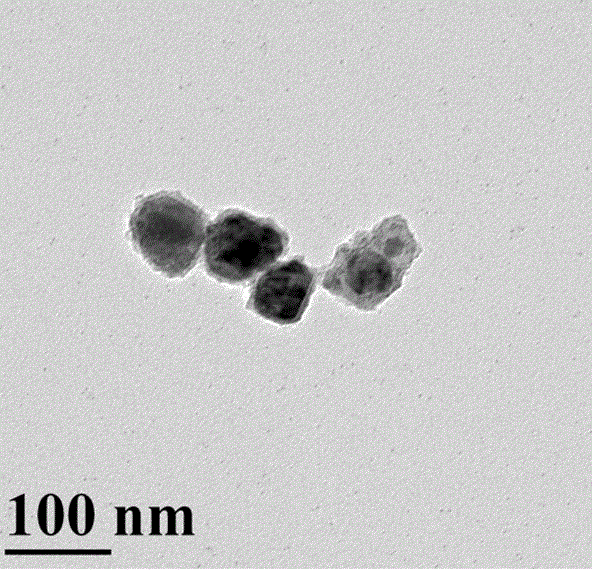

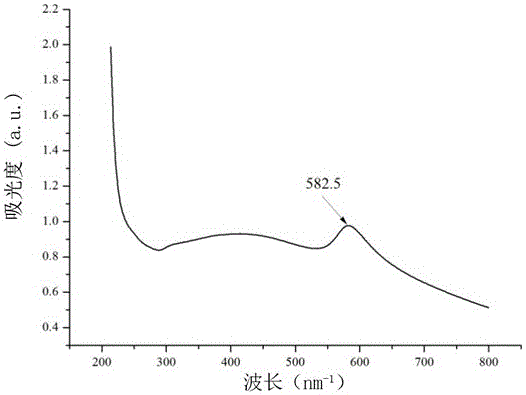

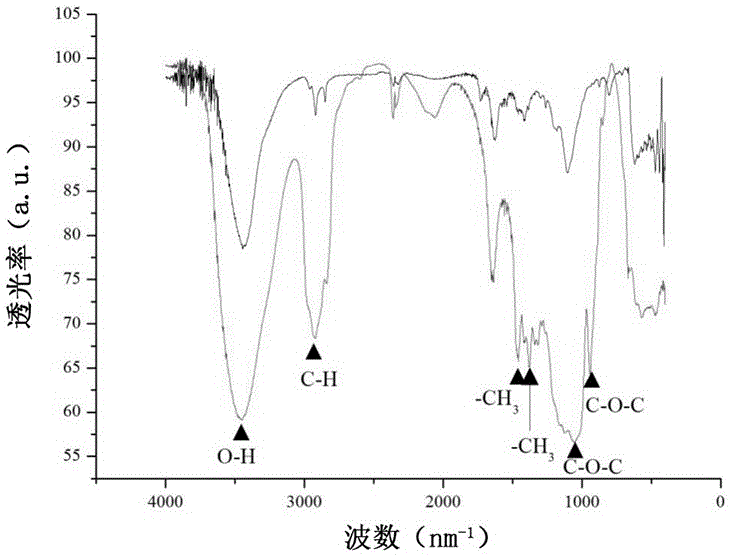

Efficient preparation method for nano-copper particles with hydroxypropyl methyl cellulose as protective agent

A technology of hydroxypropyl methylcellulose and nano-copper particles, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve problems such as inability to apply large-scale production well, waste of human and material resources, etc., and achieve Effects of reducing waste, low cost, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.1 g of hydroxypropyl methylcellulose, add it into a 250 mL three-necked flask, add 15 mL of deionized water, dissolve it under magnetic stirring, and make a hydroxypropyl methylcellulose solution;

[0032] Weigh 0.05 g of copper sulfate pentahydrate and add it to a 50 mL beaker, add 5 mL of deionized water, and dissolve it under magnetic stirring to form a copper sulfate solution;

[0033] Pour the prepared copper sulfate solution into the three-necked flask containing the hydroxypropyl methylcellulose solution, and stir magnetically for 10 minutes to mix the two evenly to obtain a mixed solution of hydroxypropyl methylcellulose-copper sulfate;

[0034] Measure 3 mL of 50% hydrazine hydrate, add it to a 50 mL beaker, and add 10 mL of deionized water to make a hydrazine hydrate solution with a mass concentration of 0.115 g / mL;

[0035] Under the action of magnetic stirring, the hydrazine hydrate solution was added dropwise to the copper sulfate-hydroxypropyl methyl...

Embodiment 2

[0038] Example 2: Same as Example 1, but the solid hydroxypropyl methylcellulose in step (1) is changed to 0.5 g, and the deionized water is changed to 150 mL.

Embodiment 3

[0039] Example 3: Same as Example 1, but the copper sulfate pentahydrate in step (2) is changed to 0.1 g, and the deionized water is changed to 20 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com