Miniature carrying device driven by liquid metal

A liquid metal and carrier technology, applied in the field of microfluidics, can solve the problems of micro carrier or high processing cost, poor flexibility, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

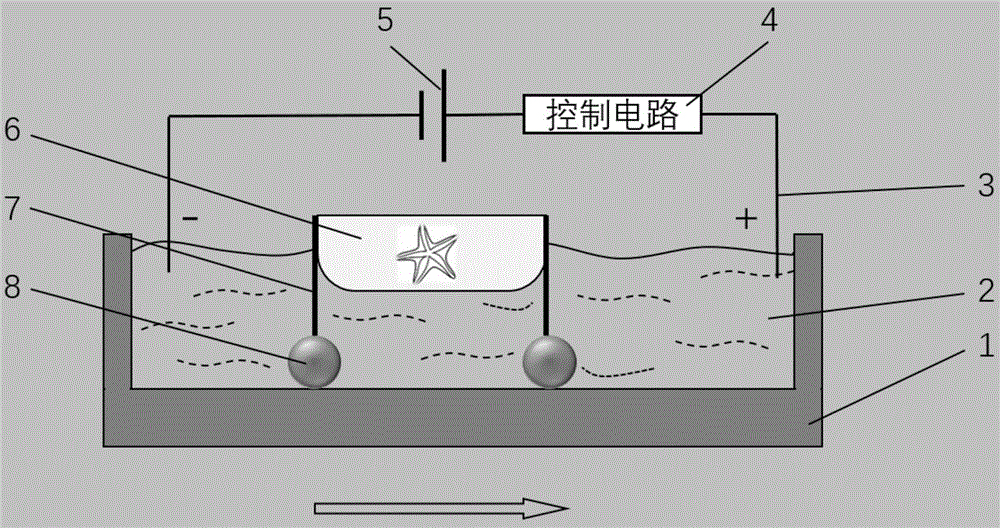

[0019] figure 1 It is a schematic side view of a liquid metal-driven micro carrier device driven by an external power supply and a control circuit according to the present invention. The electrolyte solution 2 is placed in the container 1 , and the micro carrier device includes a carrier structure 6 , an attachment structure 7 and a liquid metal wheel 8 . The carrying structure 6 is a 3D printed boat-shaped plastic structure floating on the surface of the electrolyte 2 . The attachment structure 7 is a copper rod with a diameter of 1mm, the upper end is bonded to the carrying structure 6 by glue, and the lower end is connected to the liquid metal wheel 8 through infiltration. The liquid metal wheel 8 is immersed in the electrolyte 2 . In this embodiment, the electrolyte 2 is a sodium hydroxide solution with a concentration of 0.5 mol / L. The control circuit 4 is connected to the power supply 5 and is located outside the container 1. The electrode 3 is extended through the co...

Embodiment 2

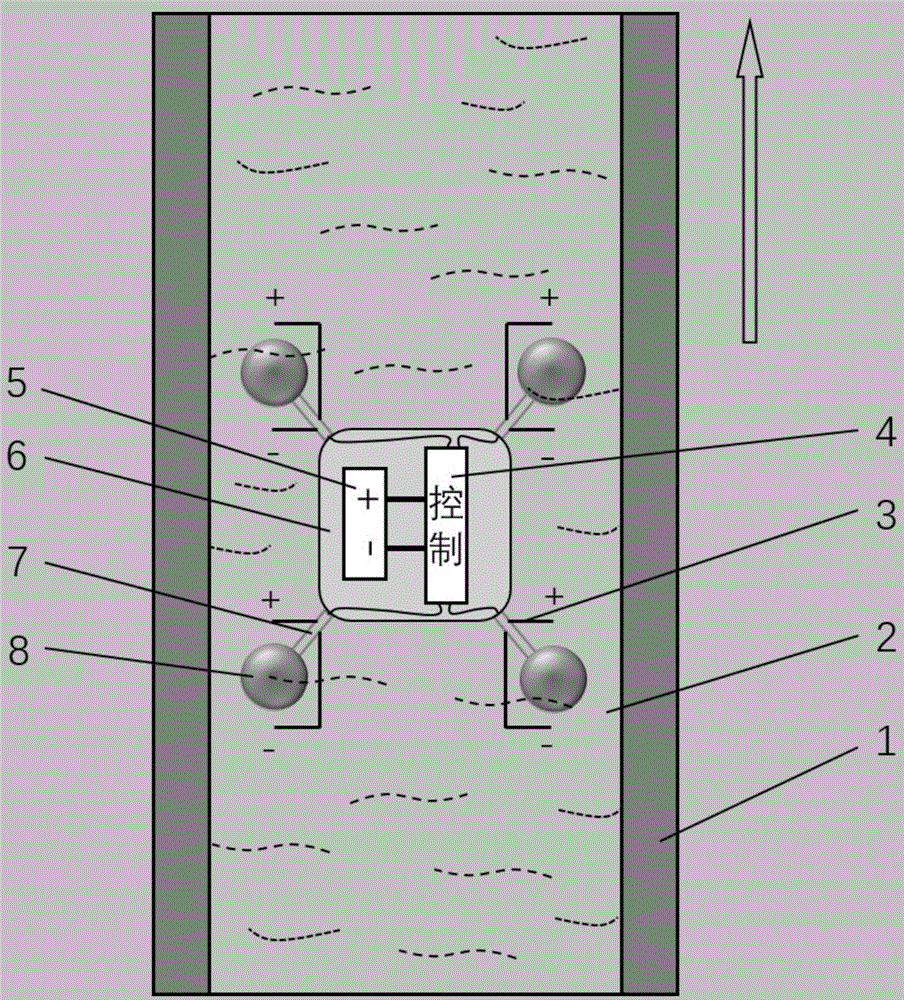

[0021] figure 2 It is a top view schematic diagram of a liquid metal-driven micro carrier device proposed by the present invention driven by a built-in power supply and control circuit. The container 1 is a channel, and the electrolyte 2 is placed in the channel. The micro-carrier includes a carrier structure 6, an attachment structure 7, and four liquid metal wheels 8. The carrier structure 6 is a 3D-printed boat-shaped plastic structure that floats on the surface of the electrolyte 2. On the surface. Electrolyte 2 is a 0.2 mol / L hydrochloric acid solution. The attachment structure 7 is a copper rod with a diameter of 1.2 mm. One end is glued to the carrying structure 6 by glue, and the other end is connected to the liquid metal wheel 8 by wetting. The non-contact end of the copper rod is attached with insulating varnish. The liquid metal wheel 8 is immersed in the electrolyte 2 . The control circuit 4 is connected to the power supply 5 and located inside the carrying str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com