Long glass fiber enhanced polypropylene material, and preparation method and application thereof

A polypropylene material and long glass fiber technology, which is applied in the field of long glass fiber reinforced polypropylene material and its preparation, can solve the problem of difficulty in ensuring uniform mass distribution of long glass fiber reinforced polypropylene material and restricting the use of long glass fiber reinforced polypropylene material. Environment, it is difficult to disperse glass fiber and additives evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

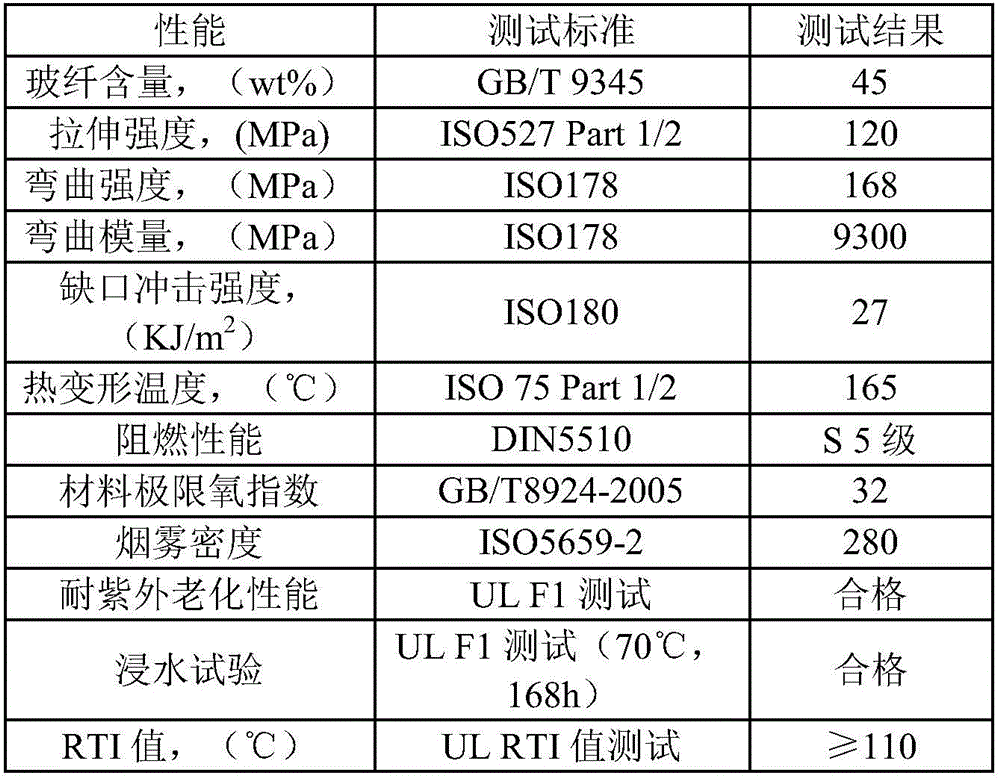

Embodiment 1

[0050] A long glass fiber reinforced polypropylene material of the present invention mainly consists of 15 parts of polypropylene resin whose melt flow rate is 60g / 10min, 10 parts of polypropylene resin whose melt flow rate is 120g / 10min, 3 parts of high-density polypropylene Vinyl resin, 3.5 parts of PP grafted maleic anhydride, 0.3 part of light stabilizer V680, 0.3 part of heat stabilizer 598, 32.5 parts of alkali-free continuous glass fiber T838T, 9.75 parts of flame retardant (brominated It is prepared by mixing styrene and antimony trioxide as a flame retardant), 0.5 parts of smoke suppressant zinc borate, 0.5 part of lubricant zinc stearate, and 1.5 parts of masterbatch containing carbon black.

[0051] The preparation method of the long glass fiber reinforced polypropylene material of the present embodiment comprises the following steps:

[0052] (1) 15 parts of high-flow high-strength polypropylene resin with a melt flow rate of 60g / 10min, 3.5 parts of PP grafted male...

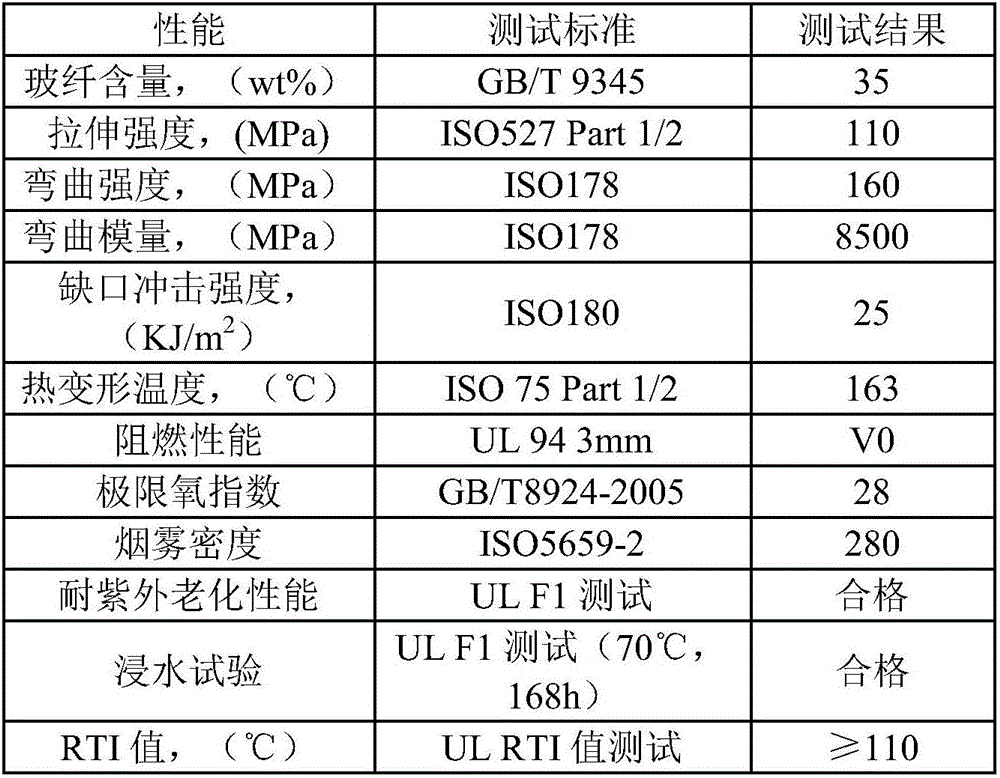

Embodiment 2

[0062] A long glass fiber reinforced polypropylene material, mainly composed of 38.1 parts of 70g / 10min high-flow high-strength polypropylene resin, 2 parts of polyethylene resin, 30 parts of glass fiber 362K, 3 parts of PP grafted maleic anhydride, 12.8 parts of flame retardant agent (decabromodiphenylethane mixed with antimony trioxide at a mass ratio of 5:1), 1 part of smoke suppressant molybdenum trioxide, 0.4 part of light stabilizer UV-531, 0.3 part of heat stabilizer DLTP, 0.3 Prepared by mixing 1 part of lubricant zinc stearate and 2.5 parts of masterbatch containing carbon black.

[0063] The preparation method of the long glass fiber reinforced polypropylene material of the present embodiment comprises the following steps:

[0064] (1) 15.4 parts of high-flow high-strength polypropylene resin with a melt flow rate of 70g / 10min, 3 parts of glass fiber compatibilizer PP grafted with maleic anhydride, 2.0 parts of masterbatch containing carbon black, and 0.3 parts of li...

Embodiment 3

[0074] A long glass fiber reinforced polypropylene material, mainly composed of 53.2 parts of high-flow high-strength polypropylene resin with a melt flow rate of 60g / 10min, 4 parts of medium-density polyethylene resin, 27.5 parts of alkali-free continuous glass fiber 4805, and 3.5 parts of PP Grafted maleic anhydride, 16.5 parts of flame retardant (a flame retardant mixed with decabromodiphenylethane and antimony trioxide at a mass ratio of 5:1), 1 part of smoke suppressant magnesium-zinc complex Ongard Ⅱ, 0.4 It is prepared by mixing 1 part of light stabilizer V680, 0.4 part of heat stabilizer 590, 0.5 part of lubricant calcium stearate, and 2 parts of masterbatch containing carbon black.

[0075] The preparation method of the long glass fiber reinforced polypropylene material of the present embodiment comprises the following steps:

[0076] (1) 16.9 parts of high-flow high-strength polypropylene resin with a melt flow rate of 60g / 10min, 3.5 parts of PP grafted maleic anhydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow velocity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Melt flow velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com