Surface nitriding and quenching composite treatment technology of metal workpiece based on lubricant storage and secondary lubrication and product

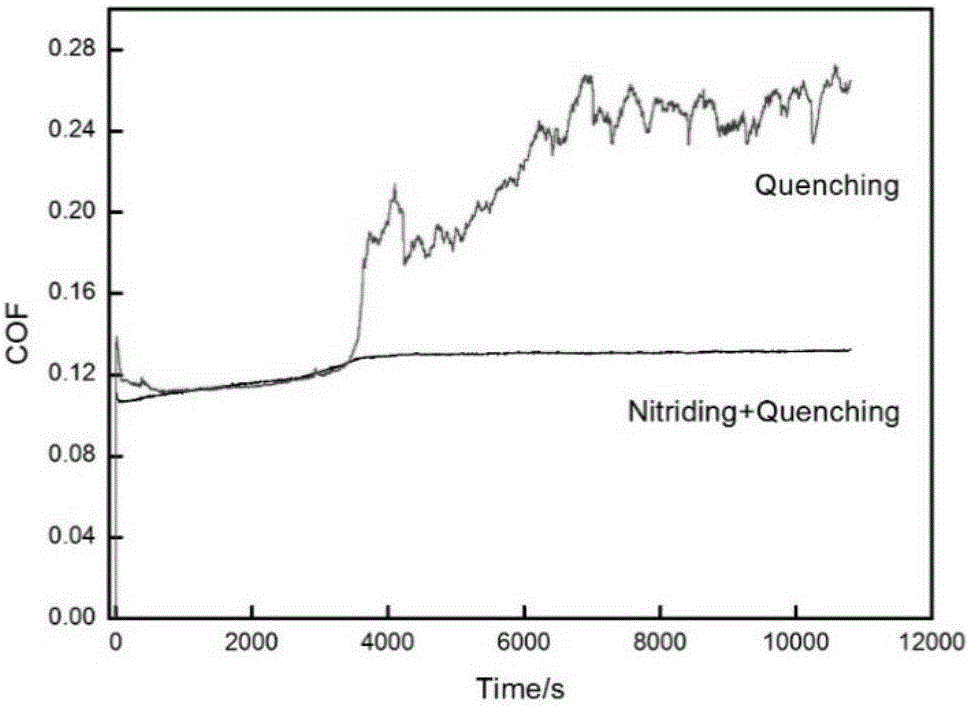

A metal workpiece, nitriding treatment technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of inability to obtain temper softening resistance, excellent surface fatigue strength, difficult high surface hardness and thick infiltration layer , long nitriding treatment time and other problems, to achieve the effect of easy promotion, lower friction coefficient and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one: GCr15 steel

[0042] Cut the sample into 15mm*15mm*5mm, heat to 600°C for stress relief annealing. Use 0# to 5# metallographic sandpaper to polish sequentially, and the polished sample is cleaned by ultrasonic and rinsed with acetone.

[0043] Gas nitriding: Put the sample into the furnace, feed pure ammonia gas, and start heating after 20 minutes. The room temperature is raised to 560°C, and the temperature is maintained for 8 hours. The ammonia gas decomposition rate is 30%-40%.

[0044] Quenching treatment: heat the sample to 850°C, keep it warm for 30min, and quench it in water.

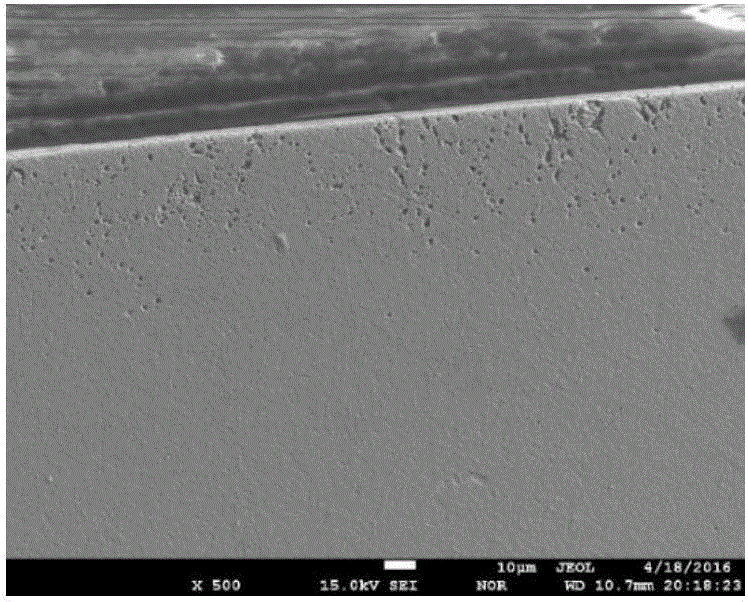

[0045] figure 1 It is the SEM picture of the sample cross-section after nitriding + quenching composite treatment of GCr15 steel. It can be seen that relatively uniform pores are distributed on the surface. After nitriding + quenching composite treatment, the hardness of the outermost layer decreased, but the hardness of the subsurface layer increased, which was about 1...

Embodiment 2

[0047] Embodiment 2: S55C steel screw

[0048] The raw material is processed into a Φ40*100mm sample, heated to 600°C for stress relief annealing. Use 0# to 5# metallographic sandpaper to polish sequentially, and the polished sample is cleaned by ultrasonic and rinsed with acetone.

[0049] Gas nitriding: Put the sample into the furnace, feed pure ammonia gas, and start heating after 20 minutes. The room temperature is raised to 530°C, and the temperature is maintained for 9 hours. The decomposition rate of ammonia gas is 25%-35%.

[0050] Quenching treatment: induction hardening is adopted, and the specific parameters are as follows:

[0051]

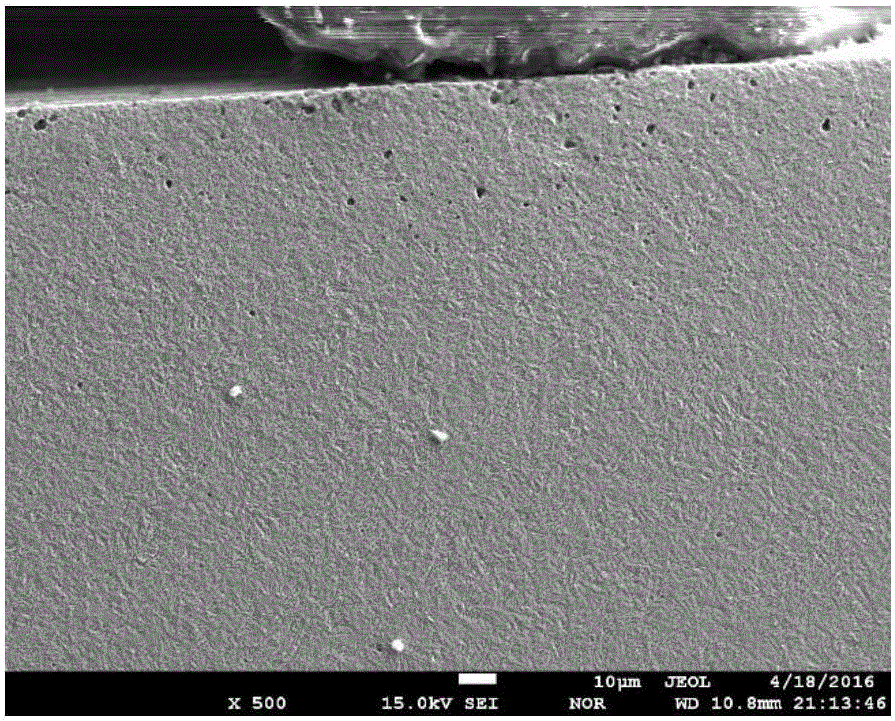

[0052] The SEM image of the cross-section of the sample after nitriding + quenching composite treatment shows ( image 3 ), the surface pores are less than GCr15 steel. After the S55C lead screw is treated with nitriding + quenching, the hardness of the outermost layer is about 520HV0.1, and the hardness of the subsurface layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com