Wolfberry drying production line

A production line, the technology of wolfberry, applied in biomass drying, drying solid materials, non-progressive dryer, etc., can solve the problems of low drying efficiency, unbalanced drying, sugar exudation of wolfberry, etc., to improve drying quality and avoid smoke The effect of pollution, not easy to absorb moisture and harden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

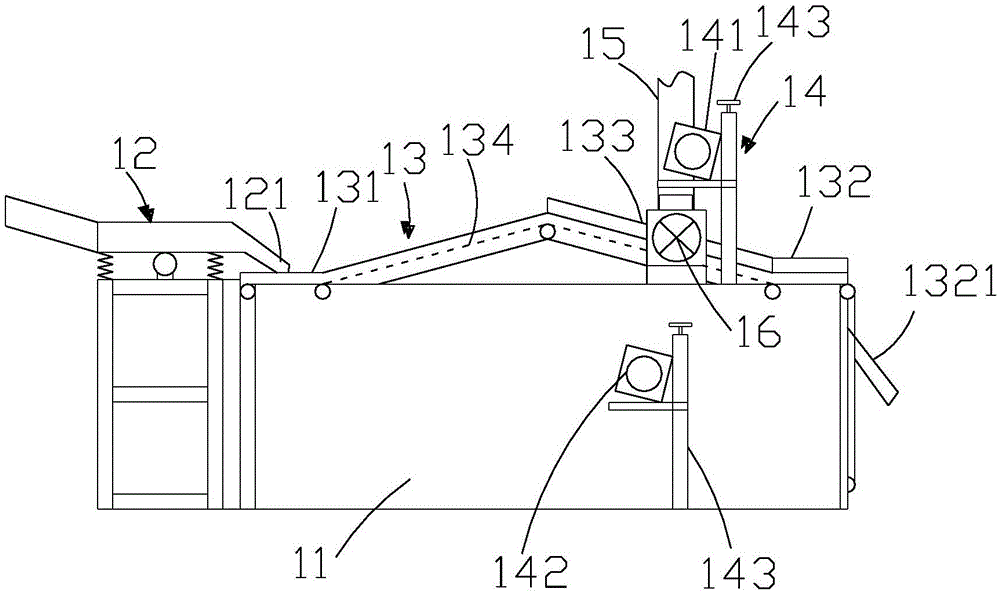

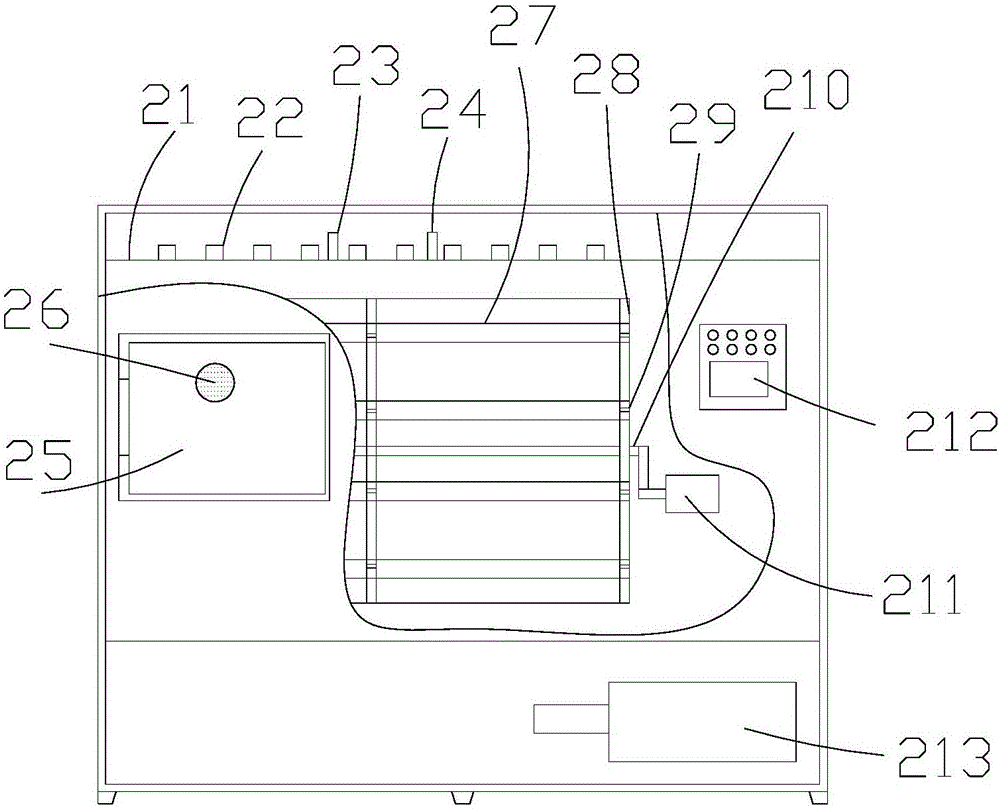

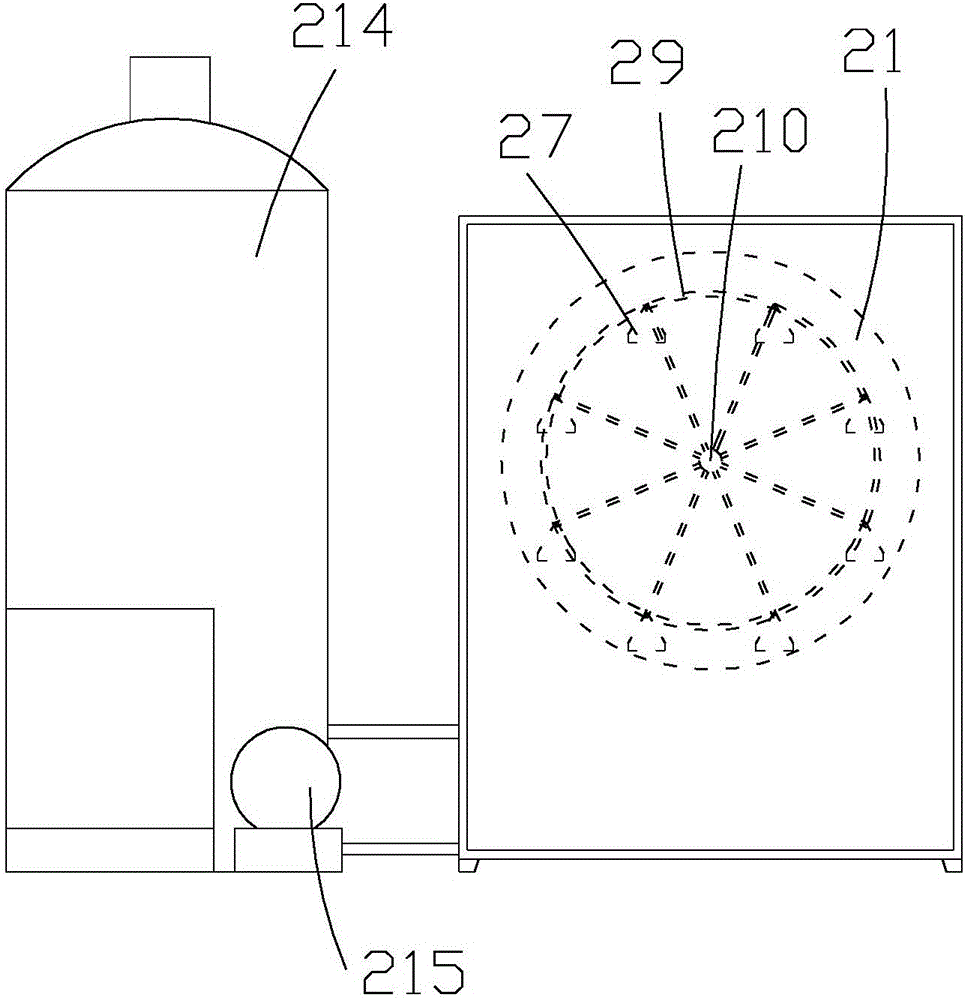

[0022] like Figure 1-3 As shown, the invention provides a wolfberry drying production line, comprising a laser puncher and a vacuum microwave drying device, wherein the wolfberry is transferred through a material basket between the laser puncher and the vacuum microwave drying device, and the laser puncher includes Frame 11, feeding assembly 12, conveying assembly 13, laser drilling assembly 14, described conveying assembly 13 is installed on the frame 11, one end of described conveying assembly 13 is feed end 131, and the other end of described conveying assembly 13 is the discharge end 132, the feeding assembly 12 is installed on the feed end 131 of the conveying assembly, the conveying assembly 13 is provided with a perforation port 133 near the discharge end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com