Preparation method for scanning probe of scanning tunneling microscope and control circuit

A scanning tunnel and scanning probe technology, applied in the field of scanning tunneling microscope scanning probe preparation and control circuit, can solve problems such as the inability to obtain aspect ratio, achieve better experimental results, easily collect voltage signals, and prevent over-corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Use sandpaper to remove the oxide film on the surface of the high-purity tungsten wire with a diameter of 0.5 mm, then soak it in dilute HCL for 10 minutes, and finally use acetone to ultrasonically clean it for 15 minutes.

[0053] The bottom of the tungsten wire is covered with a 2cm long apron, and the distance between the bottom of the apron and the bottom of the probe is 2mm.

[0054] Put the copper coil into 2mol / L KOH solution, insert the vertical tungsten wire into the center of the liquid surface of the beaker, and insert the bottom of the probe into the liquid surface to a depth of 1mm; then use the tungsten wire as the anode and the copper coil as the cathode , and a corrosion voltage of 5V is applied to both ends; the electrochemical corrosion reaction is carried out with the probe as the anode and the wire coil as the cathode.

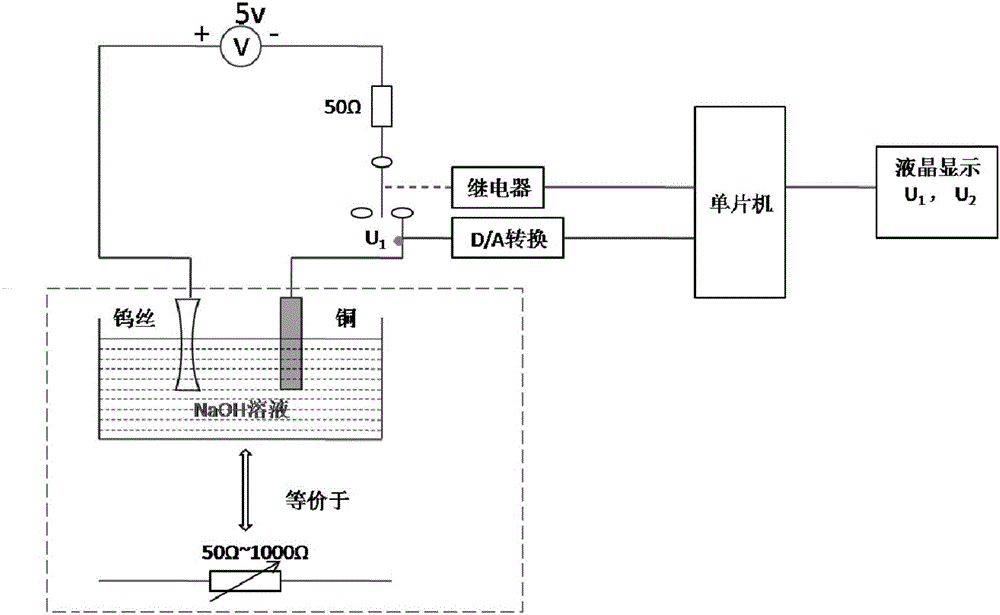

[0055] figure 1 It is also a schematic diagram of each module of the needle point preparation control circuit. The control circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com