A method for electrochemically synthesizing ferrite to treat nuclear power plant radioactive waste liquid

A technology for radioactive waste liquid and nuclear power plant, applied in electrochemical water/sewage treatment, chemical instruments and methods, radioactive purification, etc., can solve the problems of complex operation and high cost, achieve simple process, convenient operation, and not easy to secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

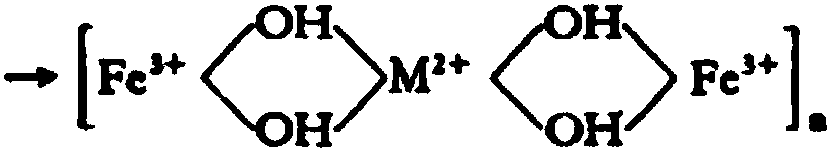

Method used

Image

Examples

Embodiment 1

[0027] The volume of the simulated waste liquid water sample is 500mL, the reaction temperature is controlled by a constant temperature water bath, and the solution is mixed by electric stirring when the lye is added dropwise.

[0028] The experimental steps are: cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dubbed as Co 2+ Concentration is 500mg / L solution, take 5ml and join in the volumetric flask of 500ml, to configure Co 2+ A simulated aqueous solution with a concentration of about 5 mg / L; then add boric acid (H 3 BO 3 ) 2.8560g, make B in the solution 3+ The concentration is 1000mg / L; then, add the electrolyte Na 2 SO 4 , and stir evenly to form the original aqueous solution; then transfer it into a 600ml container, and adjust the pH value of the solution to the experimental design value with 60g / L NaOH in an electric heating constant temperature water temperature tank at a certain temperature; select the electrode, current density, and electrode required for the exp...

Embodiment 2

[0032] The experimental procedure is the same as in Example 1, and the process parameters adopted are different from Example 1, as follows: the temperature set in the constant temperature water bath is 60°C, the initial pH of the solution adjusted by NaOH is 8, and the current density is 40mA / cm 2 , reaction time 50min, Na 2 SO 4 The concentration is 0.1mol / L, the rotation speed is 180r / min, and the electrode distance is 1cm.

[0033] The experimental results are: Co 2+ The concentration is 2.14μg / L, the total Fe concentration is 159.57μg / L, the color of the sediment is brown-black, and the magnetism is strong.

Embodiment 3

[0035] The experimental procedure is the same as in Example 1, and the process parameters adopted are different from Example 1, as follows: the temperature set in the constant temperature water bath is 60°C, the initial pH of the solution adjusted by NaOH is 8, and the current density is 50mA / cm 2 , reaction time 50min, Na 2 SO 4 The concentration is 0.1mol / L, the rotation speed is 180r / min, and the electrode distance is 1cm.

[0036] The experimental results are: Co 2+ The concentration is 1.00μg / L, the total Fe concentration is 58.54μg / L, the color is brown-black, and the magnetism is strong.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com