Treatment process of H acid industrial wastewater, device and special adsorbent resin material

An adsorption resin and treatment process technology, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of complex organic components, low resin adsorption efficiency, frequent regeneration, etc., to increase adsorption capacity, improve Effect of selective adsorption and reduction of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

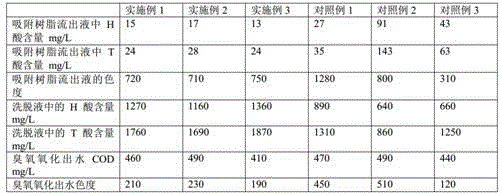

Examples

Embodiment 1

[0033] In the first step, the wastewater after H acid crystallization is extracted by adding a composite extractant mixed with ethyl acetate, kerosene and isotetradecyl alcohol in a volume ratio of 3:2:0.5. The volume ratio range of the composite extractant to wastewater It is 1:4, and the extracted water phase is sent to the second step for processing;

[0034] In the second step, the raffinate obtained in the first step is adsorbed with a chitosan-based adsorption resin modified by hydroxyl silicone oil. The effluent after adsorption is subjected to ozone oxidation treatment, the amount of ozone added in the ozone oxidation treatment is 300ppm, the reaction time is 0.5h, and the reaction temperature is 50°C to obtain the treated product water;

[0035] In the third step, the resin adsorbed in the second step is desorbed with NaOH aqueous solution. The flow rate of the eluent in the desorption process is 1.0BV / h, the temperature of the elution process is 35 ° C, and the conce...

Embodiment 2

[0042] In the first step, the wastewater after H acid crystallization is extracted by adding a composite extractant mixed with ethyl acetate, kerosene and isotetradecyl alcohol in a volume ratio of 5:4:2. The volume ratio range of the composite extractant to wastewater is It is 1: 6, the water phase after extraction is sent to the second step for processing;

[0043] In the second step, the raffinate obtained in the first step is adsorbed with a chitosan-based adsorption resin modified by hydroxyl silicone oil. During the adsorption process, the flow rate of the raw material liquid into the resin is 3.0BV / h, and the adsorption temperature is controlled at 35°C The effluent after adsorption is subjected to ozone oxidation treatment, the amount of ozone added in the ozone oxidation treatment is 800ppm, the reaction time is 1h, and the reaction temperature is 65°C to obtain the treated product water;

[0044] In the third step, the resin adsorbed in the second step is desorbed wi...

Embodiment 3

[0051] In the first step, the wastewater after H acid crystallization is extracted by adding a composite extractant mixed with ethyl acetate, kerosene and isotetradecyl alcohol in a volume ratio of 4:3:1. The volume ratio range of the composite extractant to wastewater It is 1:5, and the extracted water phase is sent to the second step for processing;

[0052] In the second step, the raffinate obtained in the first step is adsorbed with a chitosan-based adsorption resin modified by hydroxyl silicone oil. The effluent after adsorption is subjected to ozone oxidation treatment, the amount of ozone added in the ozone oxidation treatment is 500ppm, the reaction time is 0.7h, and the reaction temperature is 55°C to obtain the treated product water;

[0053] In the third step, the resin adsorbed in the second step is desorbed with NaOH aqueous solution. The flow rate of the eluent in the desorption process is 1.2BV / h, the temperature of the elution process is 37 ° C, and the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com