Bis-amino-containing MQ silicone resin, and preparation method and application thereof

A technology of MQ silicone resin and bisamino silane coupling agent, which is used in the preparation of bisamino MQ silicone resin, anti-leakage tracking agent, and the application field of addition type liquid silicone rubber, which can solve the problem of damage to the mechanical properties of silicone rubber and Processing performance, prolonging the vulcanization time of addition-type liquid silicone rubber, and low efficiency of inorganic anti-tracking agents, to achieve the effects of improving anti-tracking performance, cheap raw materials, and low nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

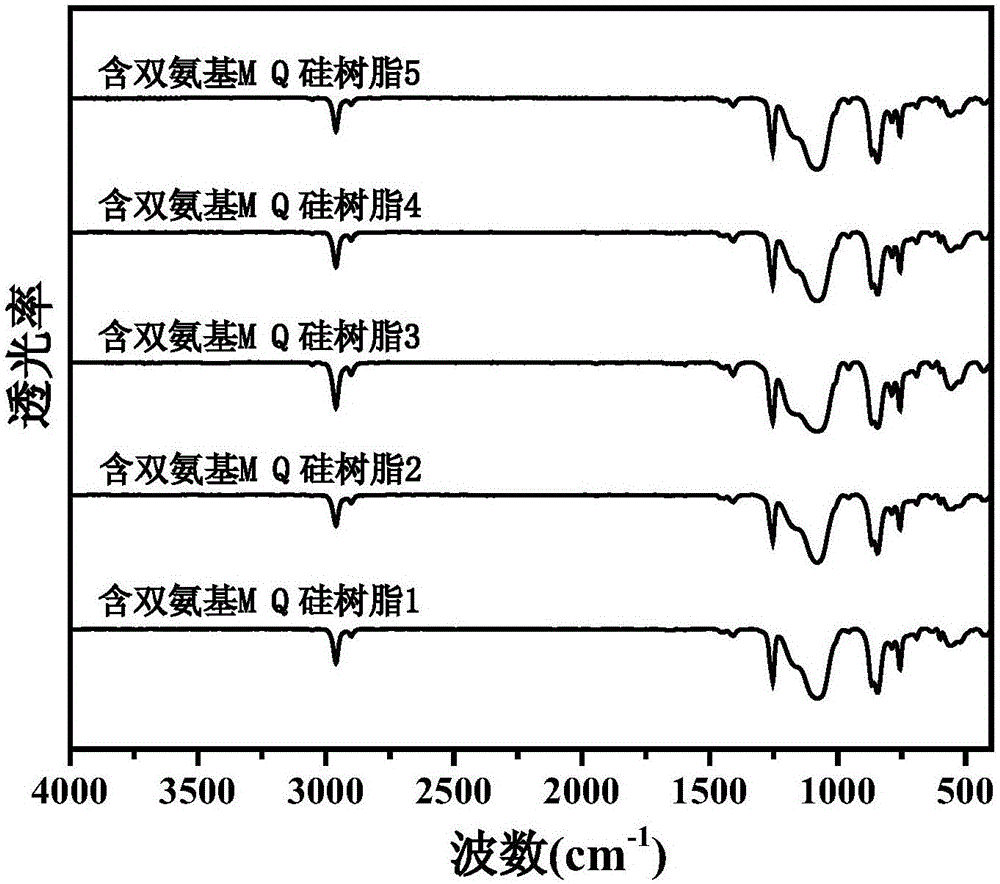

Image

Examples

Embodiment 1

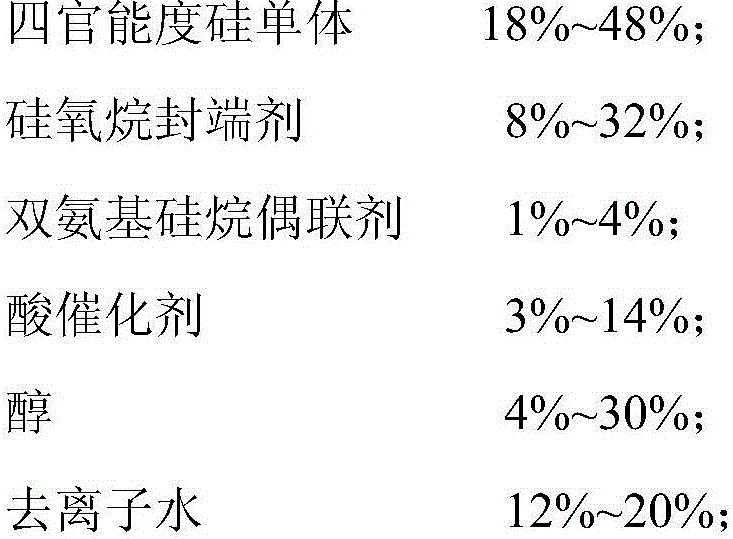

[0042] In terms of mass percent, the synthetic raw materials containing bisamino-MQ silicone resin 1 include the following components:

[0043]

[0044]

[0045]Preparation method: Add hexamethyldisiloxane, tetramethyldivinylsiloxane, tetramethyldivinylsiloxane, Deionized water, ethanol and concentrated hydrochloric acid were stirred and reacted at a temperature of 60°C for 0.5h; tetraethyl orthosilicate was added dropwise for 3h, and the reaction was continued for 1h after the addition; then γ- (β-Aminoethyl)aminopropyltriethoxysilane, the dropwise addition time is 0.5h, after the dropwise addition is completed, the temperature is raised to 70°C to continue the stirring reaction; after 2h, toluene is added for extraction, and the toluene phase is washed with deionized water To neutrality, the solvent and low boilers were distilled off under reduced pressure to obtain bisamino-containing MQ silicone resin 1.

[0046] 100 parts by mass of vinyl silicone oil (viscosity at...

Embodiment 2

[0049] In terms of mass percent, the synthetic raw materials containing bisamino-MQ silicone resin 2 include the following components:

[0050]

[0051] Preparation method: Add hexamethyldisiloxane, tetramethyldivinylsiloxane, tetramethyldivinylsiloxane, Deionized water, isopropanol and concentrated sulfuric acid were stirred and reacted at a temperature of 70°C for 1h; orthosilicate was added dropwise for 1h, and after the addition was completed, the reaction was continued for 1h; then γ -(β-Aminoethyl)aminopropyltrimethoxysilane, the dropping time is 0.5h. After the dropping is completed, the temperature is raised to 80°C to continue the stirring reaction; after 1h, toluene is added for extraction, and the toluene phase is washed with deionized water To neutrality, the solvent and low boilers were distilled off under reduced pressure to obtain bisamino-containing MQ silicone resin 2.

[0052] Change the diamino-containing MQ silicone resin 1 in Example 2 into the diamino...

Embodiment 3

[0054] In terms of mass percentage, the synthetic raw materials containing bisamino-MQ silicone resin 3 include the following components:

[0055]

[0056] Preparation method: Add hexamethyldisiloxane, tetramethyldivinylsiloxane, tetramethyldivinylsiloxane, Deionized water, butanol and p-toluenesulfonic acid, stirred and reacted at 60°C for 2h; added dropwise methyl orthosilicate for 4h, and continued to react for 0.5h after the dropwise addition; then added dropwise γ-(β-Aminoethyl)aminopropyltriethoxysilane, the dropping time is 1h, after the dropping is completed, the temperature is raised to 80°C and the reaction is continued; after 2h, toluene is added for extraction, and the toluene is washed with deionized water phase to neutral, the solvent and low boilers were distilled off under reduced pressure to obtain bisamino-containing MQ silicone resin 3.

[0057] Change the diamino-containing MQ silicone resin 1 in Example 1 into the diamino-containing MQ silicone resin 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com