High dielectric property polypropylene/nylon/whisker composite material and preparation method thereof

A composite material, polypropylene technology, applied in high dielectric performance polypropylene/nylon/whisker composite material and its preparation, reinforced polypropylene/nylon composite material and its preparation field, can solve the problem of large molding shrinkage, low Water absorption, not easy to dye, etc., to achieve good dielectric properties and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

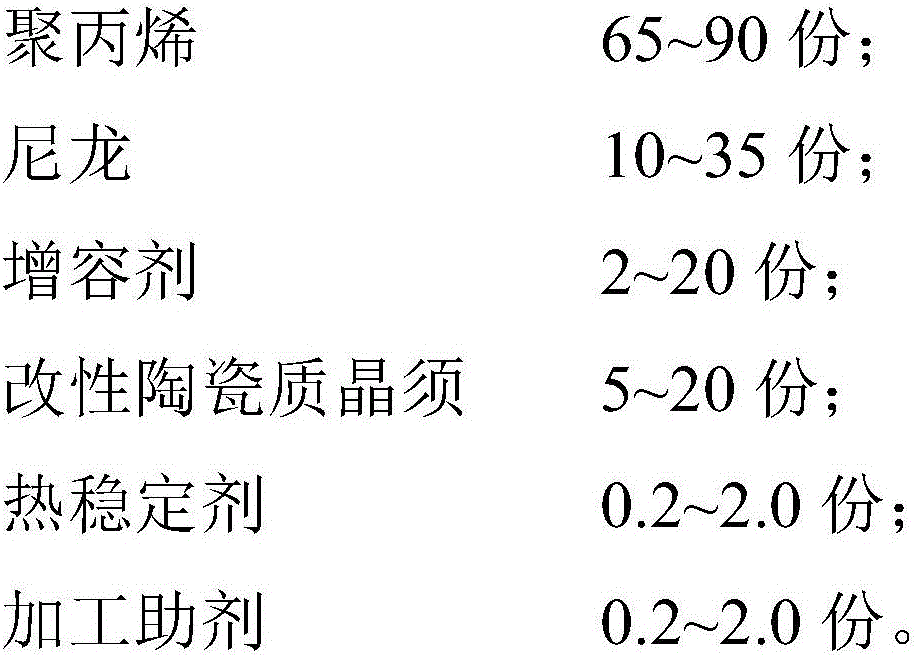

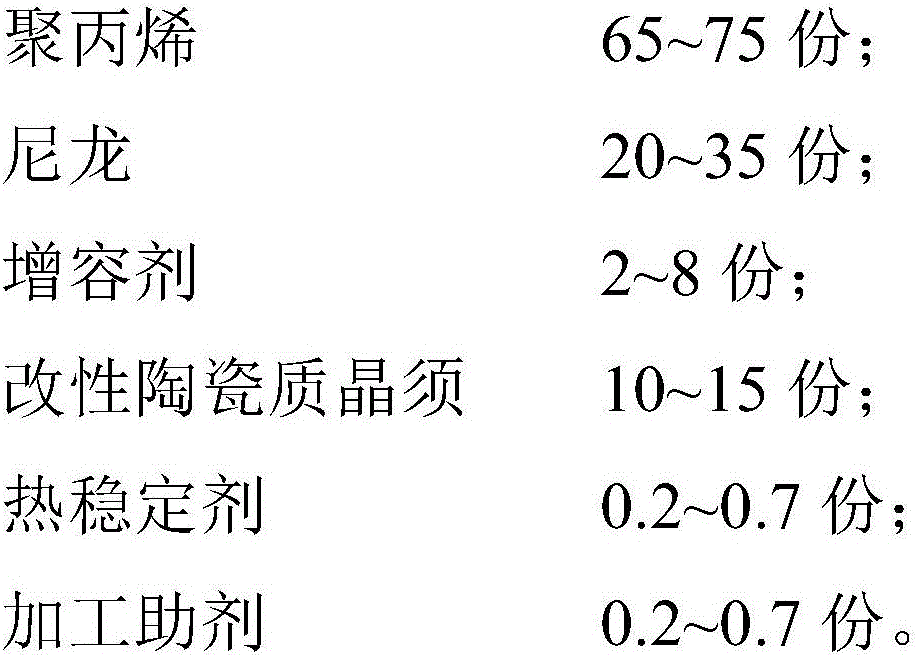

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific examples and comparative examples.

[0020] The raw materials used in the following specific examples and comparative examples are as follows, but the raw materials used in the present application are not limited to the specific models of the raw materials disclosed below.

[0021] Polypropylene (PP): The melt flow rate is 30g / 10min, and the grade is China Sea Shell EP548R; ceramic whiskers: silicon carbide, potassium titanate, aluminum borate; silane coupling agent: γ-aminopropyltriethoxy Silane (KH550), γ-glycidyl etheroxypropyl trimethoxysilane (KH560), γ-(methacryloyloxy)propyltrimethoxysilane (KH570); nylon: PA1010, produced by Shanghai Celluloid Factory ; Compatibilizer: homemade in the laboratory, maleic anhydride grafted polypropylene with maleic anhydride grafting rate of 0.88%; heat stabilizer: phosphite heat stabilizer uses Yabao 1010, phenolic heat stabilizer chooses Yabao ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com