Quantum dot material and preparation method, quantum dot membrane, backlight module and display equipment

A technology of quantum dot material and preset temperature, applied in luminescent materials, chemical instruments and methods, optics, etc., can solve problems such as affecting the display effect of liquid crystal display devices, low luminous efficiency of quantum dot films, uneven dispersion of quantum dots, etc. Achieve the effect of reducing the overlap rate, promoting development and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

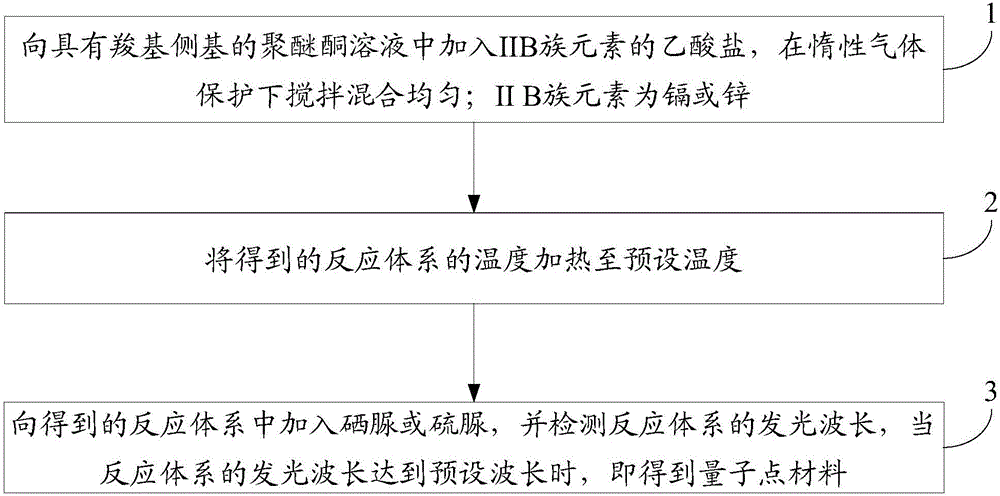

[0042] In the first aspect, an embodiment of the present invention provides a method for preparing a quantum dot material, see figure 2 , the preparation method comprises the following steps:

[0043] Step 1: Add the acetate of group II B elements to the polyether ketone solution with carboxyl side groups, stir and mix evenly under the protection of inert gas; the group II B elements are cadmium or zinc.

[0044] Step 2, heating the temperature of the reaction system obtained in step 1 to a preset temperature.

[0045] Step 3, adding selenourea or thiourea to the reaction system obtained in step 2, and detecting the luminescence wavelength of the reaction system, when the luminescence wavelength of the reaction system reaches a preset wavelength, the quantum dot material is obtained.

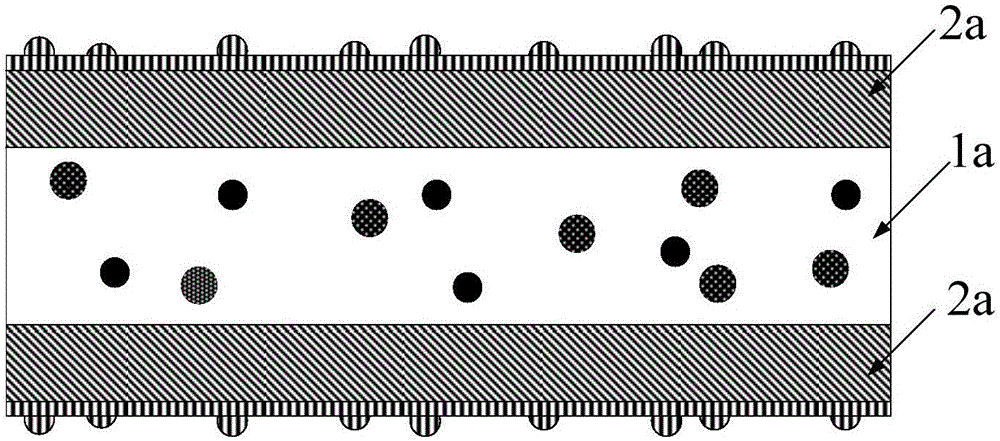

[0046] In the existing quantum dot film, the quantum dots are directly mixed with the polymer matrix, but the quantum dots are inorganic and their particle size is usually nanoscale, while the...

Embodiment 1

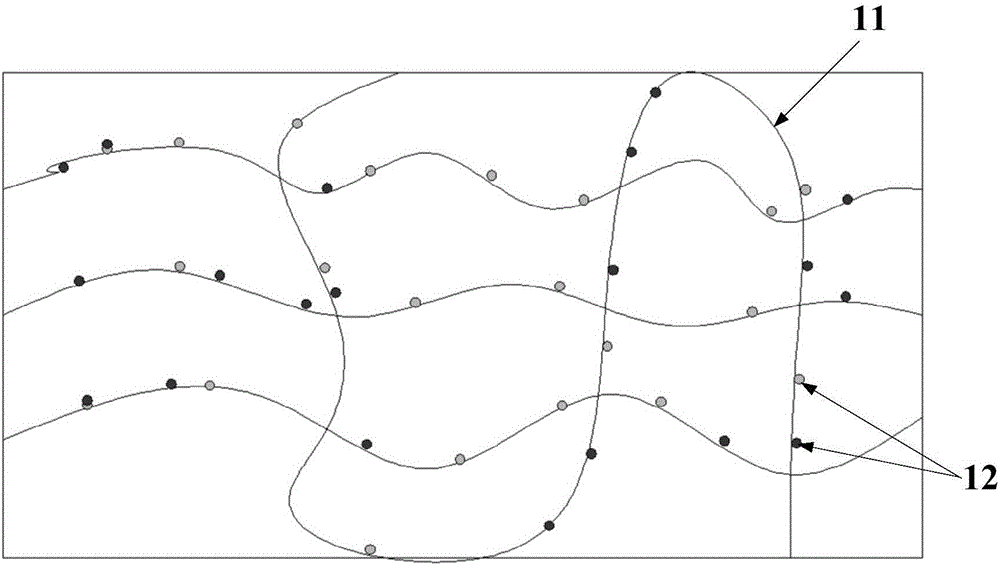

[0081] This embodiment provides a quantum dot material and a preparation method thereof. The quantum dot material uses a fully aromatic polyaryl ether ketone having carboxyl side groups represented by formula (II) as a polymer matrix, and utilizes the coordination of carboxyl side groups In-situ growth of CdSe quantum dots by in-situ interaction, controlling the distribution of CdSe quantum dots, making CdSe quantum dots uniformly dispersed in the polymer matrix, preventing CdSe quantum dots from agglomerating, and at the same time, the fully aromatic polyaryl ether ketone shown in formula (II) With high crystallinity, high density, high stiffness and good high temperature resistance, it can protect CdSe quantum dots and prevent CdSe quantum dots from failing due to water and oxygen contact.

[0082]

[0083] The preparation method of the quantum dot material provided in this embodiment is as follows:

[0084] Step 101, first prepare the wholly aromatic polyaryl ether keton...

Embodiment 2

[0099] This embodiment provides a quantum dot material and a preparation method thereof. The quantum dot material uses the fully aromatic polyaryletherketone having carboxyl side groups shown in the formula (II) in Example 1 as a polymer matrix, and utilizes the carboxyl side CdSe quantum dots are grown in situ by the coordination of the group, the distribution of the CdSe quantum dots is controlled, the CdSe quantum dots are uniformly dispersed in the polymer matrix, and the CdSe quantum dots are prevented from agglomerating. Aryl ether ketone has high crystallinity, high density, high stiffness and good high temperature resistance, which can protect CdSe quantum dots and prevent CdSe quantum dots from failing due to water and oxygen contact.

[0100] The preparation method of the quantum dot material provided in this embodiment is as follows:

[0101] Step 201, first prepare the wholly aromatic polyaryl ether ketone shown in the above formula (II), specifically as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com