Illite adsorbent as well as preparation method and application thereof

An illite and adsorbent technology, applied in the field of illite adsorbent and its preparation, can solve the problems of high preparation cost, difficult industrial application, small preparation amount, etc., and achieves short preparation time, reduced application cost and easy recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

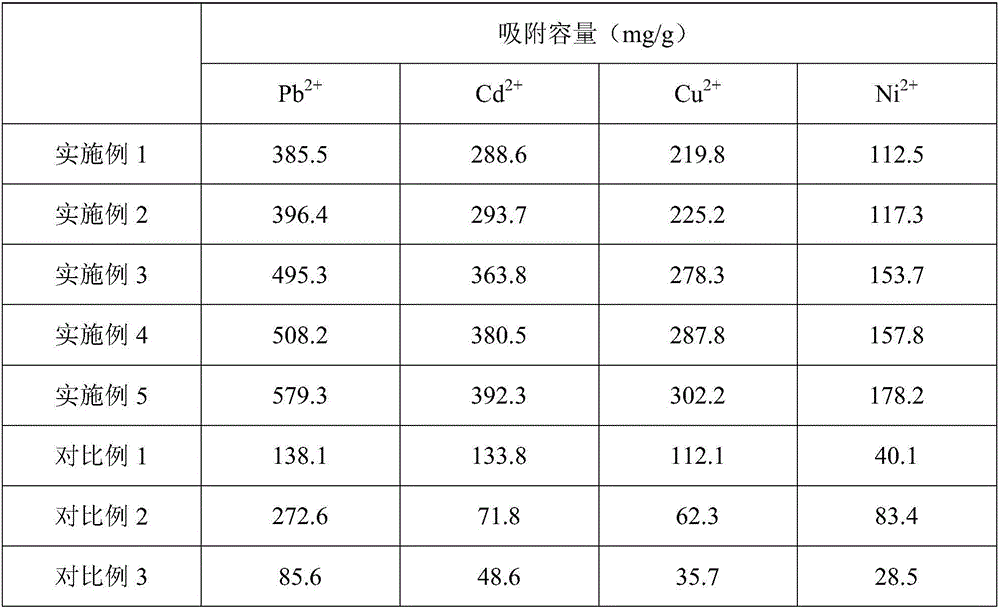

Examples

Embodiment 1

[0016] In the embodiment of the present invention, an illite adsorbent is composed of the following raw materials in parts by weight: 33 parts of illite, 1 part of triethanolamine oleate, 7 parts of thioglycolic acid, and 3 parts of trimethyl citrate.

[0017] Thioglycolic acid was mixed with 10.8 times its mass of deionized water to prepare a thioglycolic acid solution. Mix and grind illite and trimethyl citrate, pass through a 120-mesh sieve, then add thioglycolic acid solution, then raise the temperature to 143°C and seal and stir at this temperature for 42min, then lower it to 65°C and perform ultrasonic treatment at this temperature 37min, the ultrasonic power is 800W, then drip triethanolamine oleate, and then stir at a temperature of 79°C for 93min, then stir at a temperature of 100°C until dry, and then calcined at a temperature of 400°C for 3.3h. get the adsorbent.

Embodiment 2

[0019] In the embodiment of the present invention, an illite adsorbent is composed of the following raw materials in parts by weight: 41 parts of illite, 5 parts of triethanolamine oleate, 15 parts of thioglycolic acid, and 7 parts of trimethyl citrate.

[0020] Thioglycolic acid was mixed with 10.8 times its mass of deionized water to prepare a thioglycolic acid solution. Mix and grind illite and trimethyl citrate, pass through a 120-mesh sieve, then add thioglycolic acid solution, then raise the temperature to 143°C and seal and stir at this temperature for 42min, then lower it to 65°C and perform ultrasonic treatment at this temperature 37min, the ultrasonic power is 800W, then drip triethanolamine oleate, and then stir at a temperature of 79°C for 93min, then stir at a temperature of 103°C until dry, and then calcined at a temperature of 400°C for 3.3h. get the adsorbent.

Embodiment 3

[0022] In the embodiment of the present invention, an illite adsorbent is composed of the following raw materials in parts by weight: 35 parts of illite, 2 parts of triethanolamine oleate, 9 parts of thioglycolic acid, and 4 parts of trimethyl citrate.

[0023] Thioglycolic acid was mixed with 10.8 times its mass of deionized water to prepare a thioglycolic acid solution. Mix and grind illite and trimethyl citrate, pass through a 120-mesh sieve, then add thioglycolic acid solution, then raise the temperature to 143°C and seal and stir at this temperature for 42min, then lower it to 65°C and perform ultrasonic treatment at this temperature 37min, the ultrasonic power is 800W, then drip triethanolamine oleate, and then stir at 79°C for 93min, then stir at 101°C until dry, and then calcined at 400°C for 3.3h. get the adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com