Brittle material punching method

A brittle material, processing brittle technology, applied in the field of laser drilling, can solve problems such as affecting production efficiency, affecting material strength, material stress accumulation, etc., to achieve the effect of reducing the scope of action, reducing the difficulty of splitting, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below by specific embodiment the present invention is described in further detail:

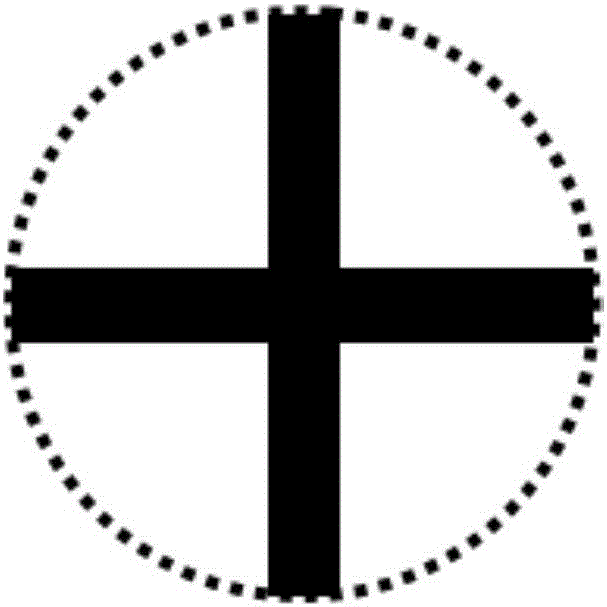

[0028] The principle of the compound processing method in the present invention is: the ultrashort pulse laser is used to cut the sapphire into filaments, combined with the laser ablation technology to ablate the partial area of the cutting center, combining the advantages of the two drilling techniques, to a certain extent, the The problem caused by stress release is eliminated, and the difficulty of splitting is significantly reduced.

[0029] Specifically, the scheme adopted in the present invention is:

[0030] like image 3 As shown, first draw a hollow ring with a diameter of 1 mm in the motion control software, adjust the appropriate parameters and turn on the laser, and the laser cuts a ring with a diameter of 1 mm on the sapphire surface through the cutting head and penetrates the sapphire layer (such as figure 1 As shown, the ring is an approximate ring, which is actually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com