A purifying device and a purifying method for an aluminium nitride raw material

The technology of a purification device and a purification method is applied in the field of purification devices for aluminum nitride raw materials, which can solve the problems of reduced life, damage to the metal insulation layer of a metal heater, easy introduction of other impurities, etc., so as to prolong the service life and reduce the heat Lost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

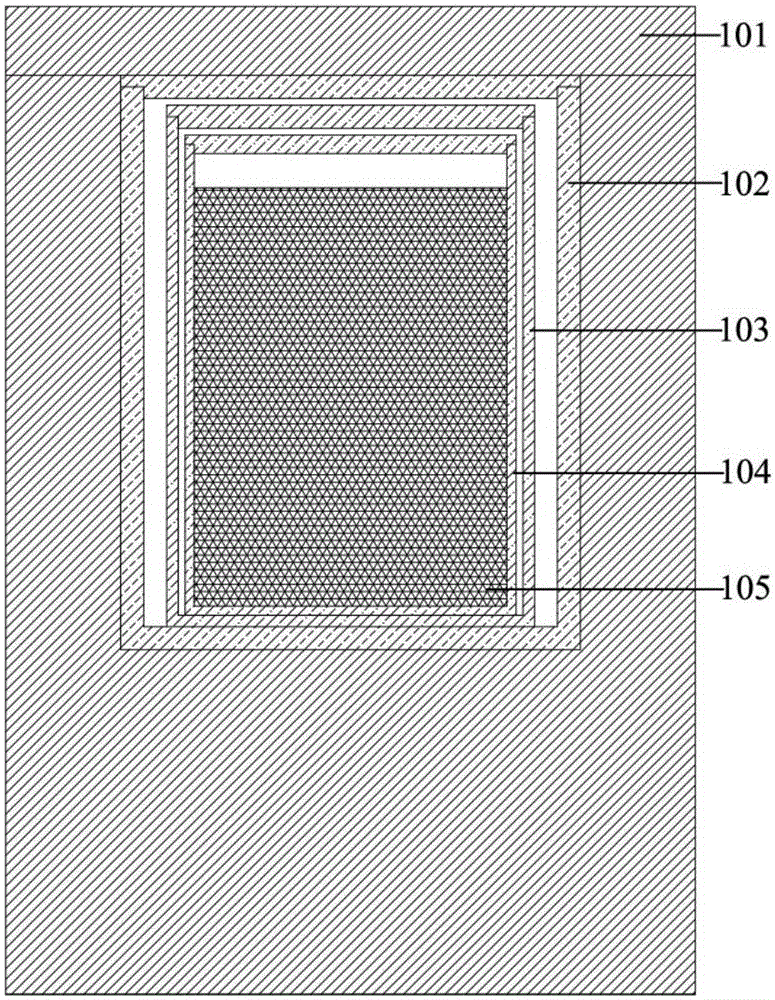

[0039] 1. Measure the size of the intermediate frequency induction coil, wrap a carbon felt cylinder containing the heating cylinder 102, and cut out the upper insulation layer, thus forming the insulation layer 101.

[0040] 2. Open the upper cover of the insulation layer 101 and the heating cylinder 102 , and place the isolation crucible 103 in the heating cylinder 102 .

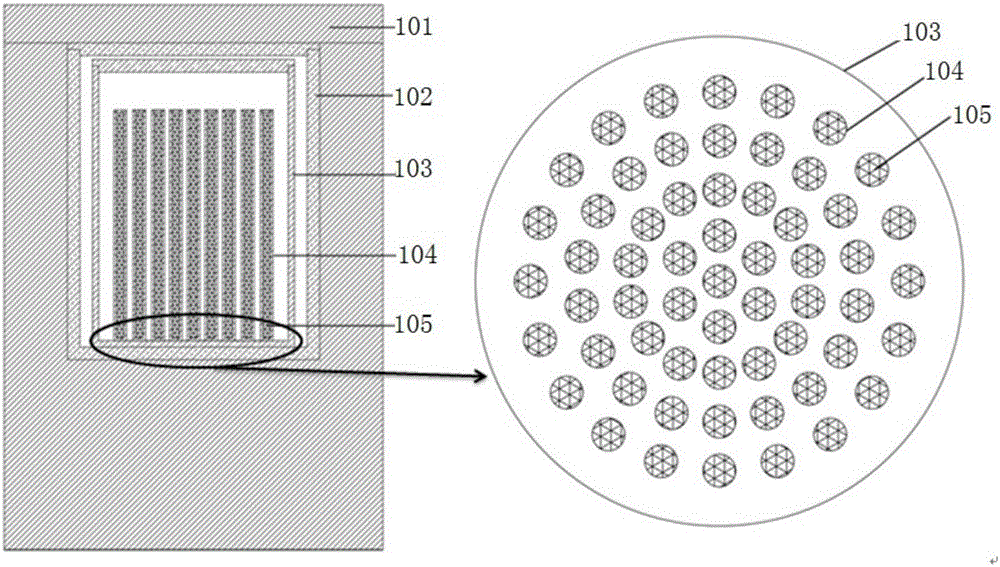

[0041] 3. Fill the aluminum nitride raw material 105 (powder) in the raw material crucible 104, in order to make the aluminum nitride raw material 105 (powder) uniform in each space position in the raw material crucible 104, it can be filled in multiple batches, Such as three times.

[0042] 4. Open the cover of the isolation crucible 103, and place the raw material crucible 104 containing the aluminum nitride raw material 105 (powder) in the isolation crucible 103.

[0043] 5. Make the center lines of the raw material crucible 104, the isolation crucible 103, the heating cylinder 102, and the insulation ...

Embodiment 2

[0047] 1. Measure the size of the intermediate frequency induction coil, wrap a carbon felt cylinder containing the heating cylinder 102, and cut out the upper insulation layer, thus forming the insulation layer 101.

[0048] 2. Open the upper cover of the insulation layer 101 and the heating cylinder 102 , and place the isolation crucible 103 in the heating cylinder 102 .

[0049] 3. Fill the aluminum nitride raw material 105 (powder) in the raw material crucible 104, in order to make the aluminum nitride raw material 105 (powder) uniform in each space position in the raw material crucible 104, it can be filled in multiple batches, Such as three times.

[0050] 4. Open the cover of the isolated crucible 103, place the raw material crucible 104 containing the aluminum nitride raw material 105 (powder) in a pit with a certain depth on the bottom surface of the isolated crucible 103, and then place the retainer on the outside of the crucible to Make the crucible stable. The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com