Preparation method of phosphorus modified multistage pore ZSM-5 zeolite

A ZSM-5, multi-level pore technology, applied in the field of inorganic material synthesis and catalysis, to achieve the effects of enhancing hydrothermal stability, improving selectivity, and simple modification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] a) Add 1 g of hierarchically porous ZSM-5 zeolite to 10 ml of phosphoric acid solution containing 0.01 g of phosphorus, and stir at room temperature for 2 h to disperse it evenly;

[0043] b) rotating the mixture obtained in step a) at 80° C. for 2 h;

[0044] c) drying the dried powder obtained in step b) in an oven at 120° C. for 2 hours;

[0045] d) Remove the sample from the oven. Calcining in a muffle furnace at 600° C. for 4 h with a heating rate of 2° C. / min to obtain a phosphorus-modified hierarchically porous ZSM-5 zeolite with a phosphorus modification amount of 1 wt%.

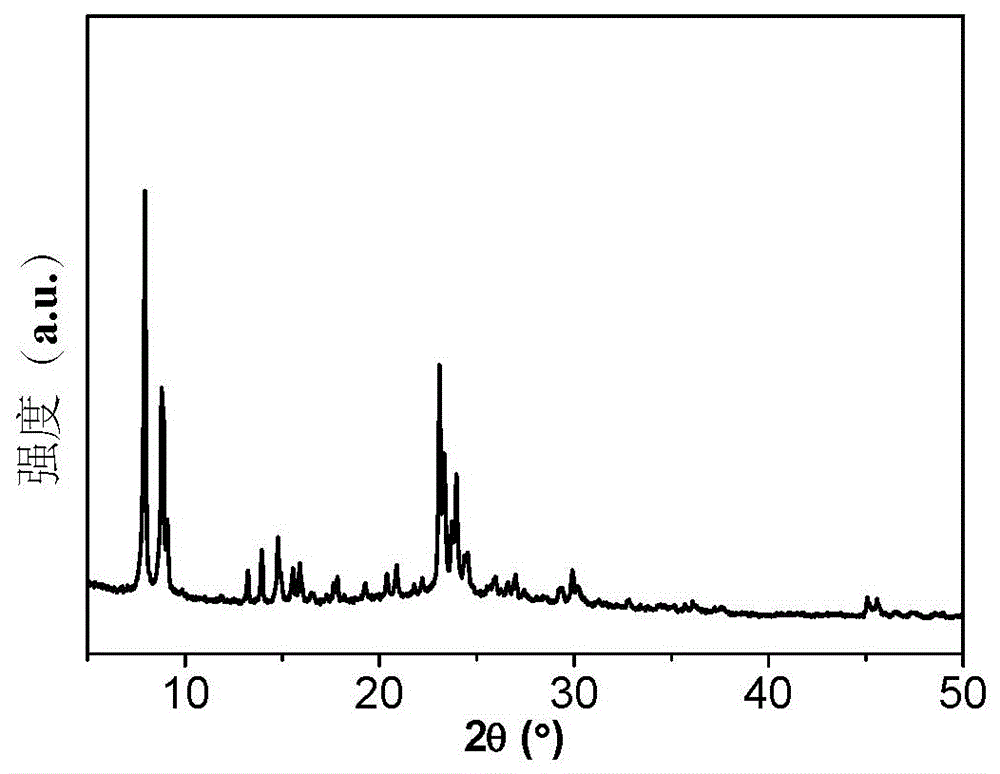

[0046] figure 1 This is the XRD pattern of the phosphorus-modified hierarchically porous ZSM-5 zeolite prepared in Example 1. It can be seen from the figure that the material has a typical MFI zeolite structure with a very high crystallinity.

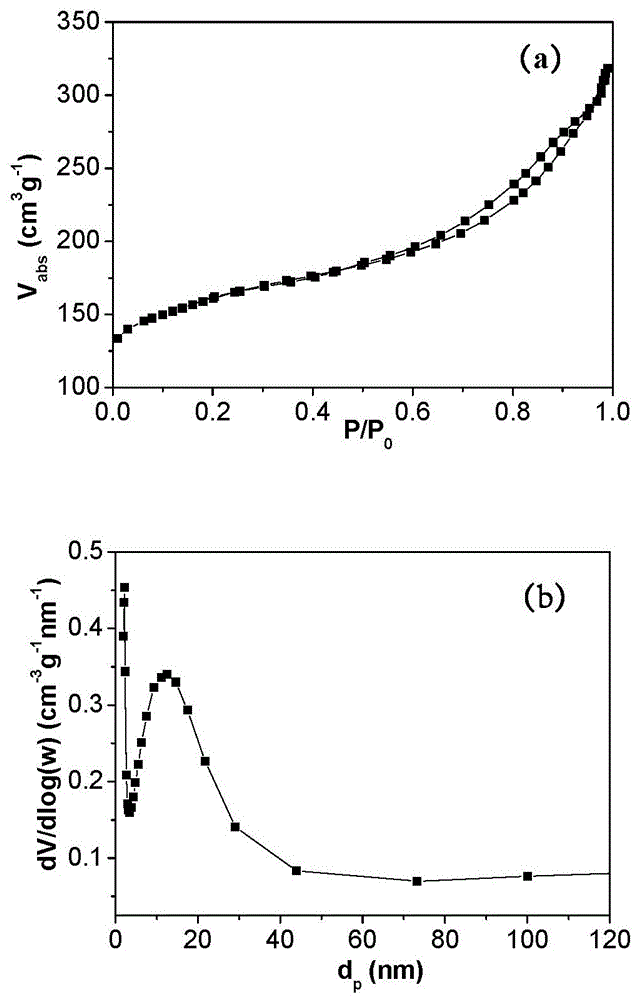

[0047] figure 2It is the nitrogen adsorption-desorption isotherm (a) and pore size distribution figure (b) of the phosphorus-modified multi-stage ...

Embodiment 2

[0052] The difference between this example and Example 1 is only that the mass of phosphorus contained in the solution is 3% of the mass of the hierarchically porous ZSM-5 zeolite, and the rest of the content is the same as in Example 1.

[0053] Figure 5 It is the XRD diffraction pattern and the nitrogen adsorption-desorption isotherm of the phosphorus-modified hierarchically porous ZSM-5 zeolite prepared in Example 2. It can be seen from the figure that the material is a typical MFI zeolite structure with very high crystallinity. Moreover, the nitrogen adsorption-desorption isotherm is a typical IV-type isotherm and H1-type hysteresis loop, at 0.60 <0.9 There is an obvious breakthrough in adsorption, indicating the existence of mesoporous structure.

[0054] Image 6 SEM and TEM photographs of the phosphorus-modified hierarchically porous ZSM-5 zeolite prepared in Example 2, we can find from the SEM image that the material is nano-spherical particles. Its rough surface h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com