Monoclinic phase vanadium dioxide nanowire and preparation method and application thereof

A vanadium dioxide nanometer, monoclinic phase technology, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of complex process, low safety factor, complicated method, etc., and achieves simple preparation process, low production cost and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of monoclinic phase VO of the present invention 2 The preparation method of nanowires specifically includes the following steps:

[0037] (1) 1.82g (0.01mol) vanadium pentoxide and 11.38g (0.04mol) stearic acid were added to 80mL deionized water, stirred for 30 minutes to form a turbid liquid;

[0038] (2) transfer the obtained turbid liquid to a 100mL hydrothermal reactor (the filling rate of the reactor is 80%), and perform a hydrothermal reaction at 280° C. for 12h;

[0039](3) After the hydrothermal reaction is completed, after the reactor is naturally cooled, the product in the reactor is taken out and centrifuged, and the product obtained after the centrifugation is alternately washed 3 times with acetone and absolute ethanol, and finally at 80 ° C. Under vacuum drying for 12h, the monoclinic phase VO was obtained. 2 Nanowires.

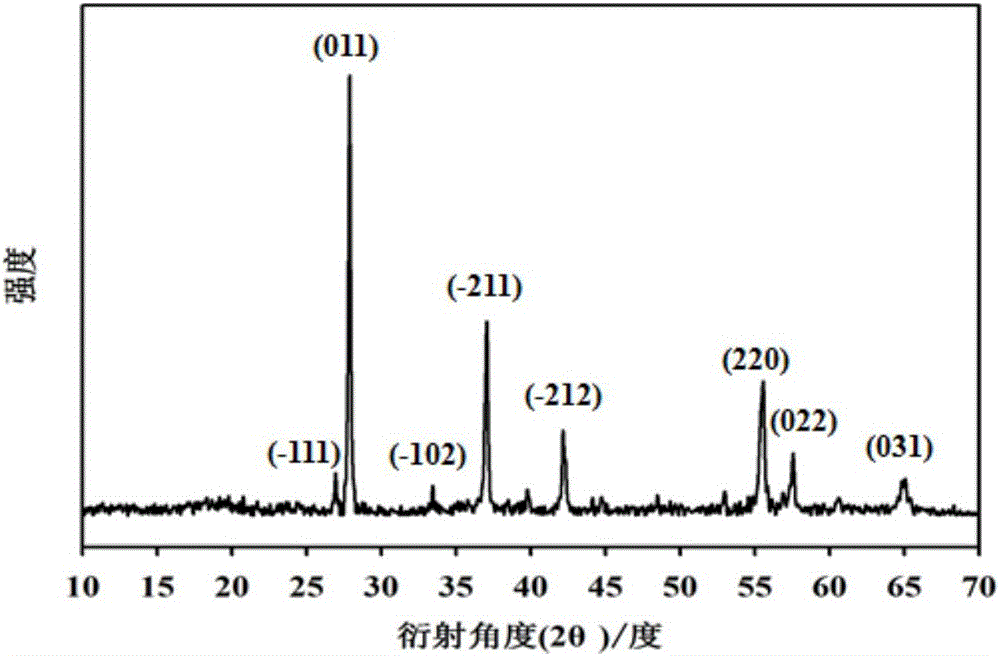

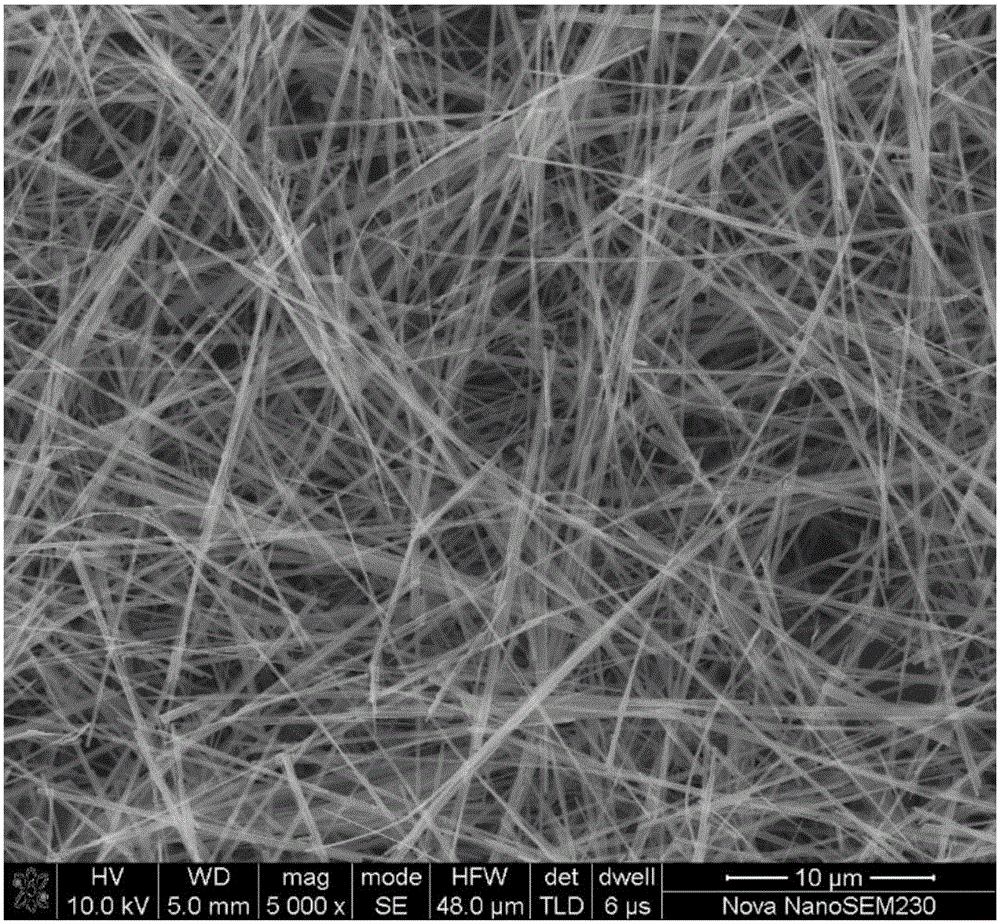

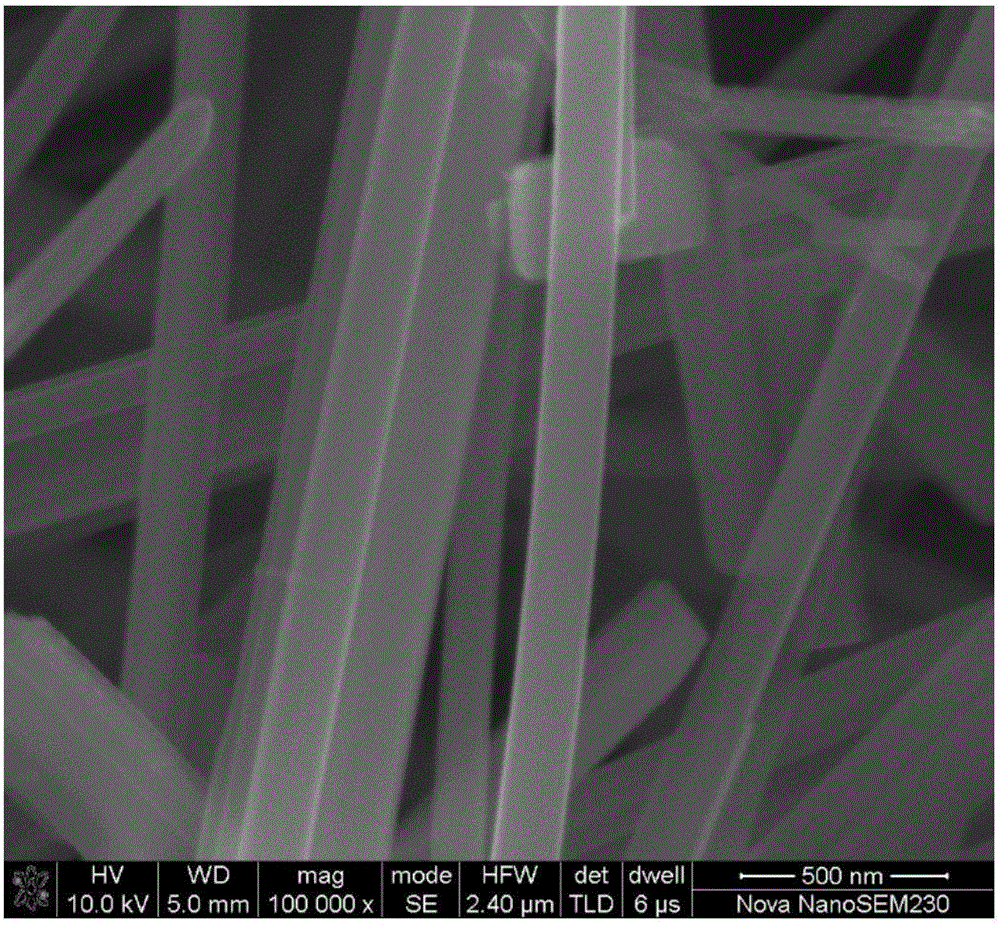

[0040] figure 1 VO prepared in this example 2 XRD pattern of nanowires, it can be seen from the figure that VO 2 The nanowi...

Embodiment 2

[0042] A kind of monoclinic phase VO of the present invention 2 The preparation method of nanowires specifically includes the following steps:

[0043] (1) 1.82g (0.01mol) vanadium pentoxide and 5.69g (0.02mol) stearic acid were added to 80mL deionized water, stirred for 30 minutes to form a turbid liquid;

[0044] (2) transfer the obtained turbid liquid to a 100mL hydrothermal reactor (the filling rate of the reactor is 80%), and perform a hydrothermal reaction at 280° C. for 18h;

[0045] (3) After the hydrothermal reaction is completed, after the reactor is naturally cooled, the product in the reactor is taken out and centrifuged, and the product obtained after the centrifugation is washed alternately with acetone and dehydrated ethanol 3 times in turn, and finally at 60 ° C Under vacuum drying for 15h, the monoclinic phase VO was obtained. 2 Nanowires.

[0046] After testing, the VO prepared in this example 2 Nanowires with uniform size distribution, smooth surface and...

Embodiment 3

[0048] A kind of monoclinic phase VO of the present invention 2 The preparation method of nanowires specifically includes the following steps:

[0049] (1) 1.82g (0.01mol) vanadium pentoxide and 17.07g (0.06mol) stearic acid were added to 80mL deionized water, and stirred for 30 minutes to form a turbid liquid;

[0050] (2) transfer the obtained turbid liquid to a 100mL hydrothermal reactor (the filling rate of the reactor is 80%), and perform a hydrothermal reaction at 260° C. for 24h;

[0051] (3) After the hydrothermal reaction is completed, after the reactor is naturally cooled, the product in the reactor is taken out and centrifuged, and the product obtained after the centrifugation is alternately washed 3 times with acetone and absolute ethanol, and finally at 100 ° C. Under vacuum drying for 8h, the monoclinic phase VO was obtained. 2 Nanowires.

[0052] After testing, the VO prepared in this example 2 The size distribution of nanowires is uniform (diameter is 120-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com