Method for comprehensive utilization of waste gases and waste residues

A waste residue and waste gas technology, applied in cement production and other directions, can solve problems such as ineffective utilization and environmental problems, achieve good economic and environmental protection benefits, reduce production costs and use costs, and achieve remarkable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Table 1 is the ratio table of raw materials in this embodiment. The raw materials are weighed according to Table 1, and then the silicon-calcium slag (A), waste limestone (B) and slag (C) are crushed, ground, batched, mixed, and homogenized and other processes, similar to the Portland cement raw meal preparation process, the fineness of the mixed material is controlled to be 80 μm and the sieve residue is less than 5%, the Ca / Si molar ratio is controlled to be 2.0, and it is calcined at a low temperature at a temperature of 1150 ° C. 60min, and then rapidly cooled to obtain the active material, which was lowered to below 100°C in 30 minutes; the active material was mixed with water, the proportions were 90% and 10%, and vibration molding was made into a 100mm×100mm×100mm block, and then the first-stage high-efficiency gas Fully participate in the reaction in the absorption reaction tower, the temperature is 100-150°C, CO 2 Concentration 35%, SO 2 Concentration 0.002%, ...

Embodiment 2

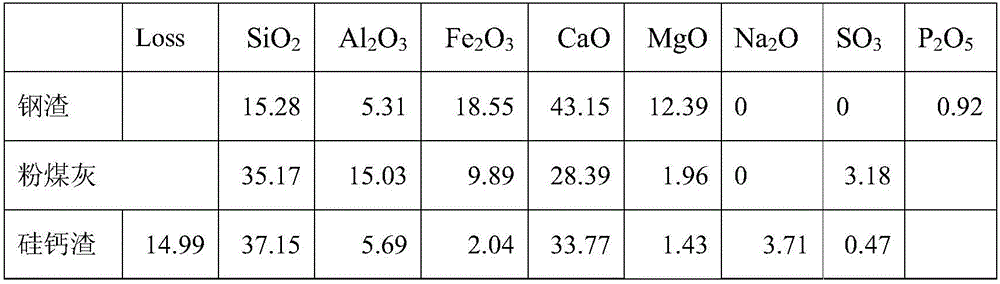

[0041]Table 2 is the raw material ratio table of this embodiment. Weigh the raw materials according to Table 2, and then pass steel slag (A), fly ash (B) and calcium silicate slag (C) through a process similar to the preparation process of Portland cement raw meal , crushing, grinding, batching, mixing, homogenization and other processes, the fineness of the mixed material is controlled to be 80 μm and the sieve residue is less than 5%, the Ca / Si molar ratio is controlled to be 1.0, and it is calcined at a low temperature at a temperature of 1250 ° C. for 30 minutes, and then rapidly cooled to obtain the active material, which was lowered to below 100°C in 30 minutes; the active material was mixed with water and sand at a ratio of 45%, 10% and 45% respectively, and vibrated to form a 240mm×115mm×53mm brick, and then in Fully participate in the reaction in the first-stage high-efficiency gas absorption reaction tower, the temperature is 100-150°C, CO 2 Concentration 35%, SO 2 ...

Embodiment 3

[0045] Waste incineration bottom slag (A), steel slag (B) and high-calcium fly ash (C) are processed through crushing, grinding, batching, mixing, homogenization, etc., similar to the preparation process of Portland cement raw meal, and the mixture is controlled The fineness of the material is 80 μm, the sieve residue is less than 5%, the Ca / Si molar ratio is controlled to be 2.5, and it is calcined at a low temperature, the calcination temperature is 1250°C, and the calcination time is 60 minutes, and then the active material is obtained by rapid cooling, which is reduced to below 100°C in 30 minutes Active substances, water, sand and stone are mixed in proportions of 17%, 8%, 67% and 8% respectively, vibrated and formed into 100mm×100mm×10mm plates, and then fully participated in the first-level high-efficiency gas absorption reaction tower Reaction, temperature 250-300°C, CO 2 Concentration 35%, SO 2 Concentration 0.002%, humidity 9%. After 4 hours of full reaction, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com