Method for improving bioactivity of block HA bio-material

A biological material and bioactive technology, applied in the field of bioceramic material preparation, can solve problems such as poor mechanical properties, limit wide application, and reduced activity, and achieve the effects of low cost, easy industrialization, and promotion of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this example, see Figure 1~4 , a method for improving the bioactivity of a biomaterial of bulk HA, comprising the steps of:

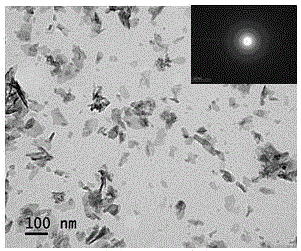

[0026] a. Prepare nano-HA powder by precipitation method, put the nano-HA powder in a drying oven and dry it completely for use. The appearance of the nano-HA powder is as follows: figure 1 As shown, HA is hydroxyapatite;

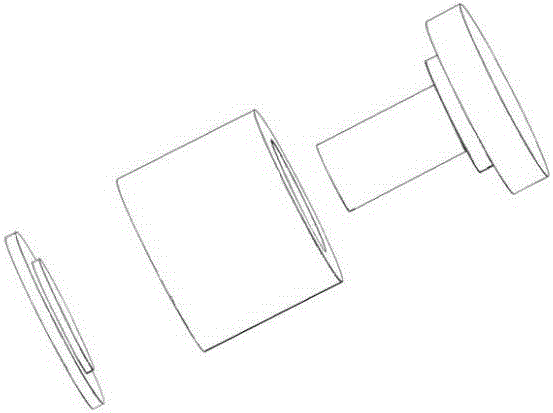

[0027] b. Using a prefabricated mold for processing bioceramic disc samples, such as figure 2 As shown, then spread the nano-HA powder prepared in step a in the female mold of the pressing mold, apply a set load to the mold with a universal testing machine controlled by a microcomputer, press and form the HA block, and then place the HA block The blank is out of the mold for use;

[0028] c. Sintering the HA block green body prepared in the step b at a high temperature of 1500°C, and then cooling with the furnace to decompose the hydroxyapatite in the HA block to prepare the HA block;

[0029] d. Mix the decomposed HA...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

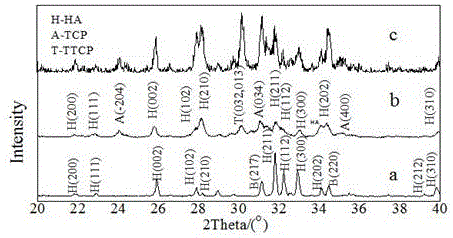

[0033] In this comparative example, see image 3 , a method for improving the bioactivity of the biomaterial of bulk HA, comprising the steps of:

[0034] A method for improving the bioactivity of the biomaterial of bulk HA, comprising the steps of:

[0035] a. Prepare nano-HA powder by precipitation method, put the nano-HA powder in a drying oven and dry it completely for use. The appearance of the nano-HA powder is as follows: figure 1 As shown, HA is hydroxyapatite;

[0036] b. Using a prefabricated mold for processing bioceramic disc samples, such as figure 2 As shown, then spread the nano-HA powder prepared in step a in the female mold of the pressing mold, apply a set load to the mold with a universal testing machine controlled by a microcomputer, press and form the HA block, and then place the HA block The blank is out of the mold for use;

[0037] c. Sintering the HA block green b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com