Vaporization energy saving equipment for silicone monomer raw material methyl chloride and process thereof

A methyl chloride and organosilicon technology, which is applied in the field of organosilicon monomer production equipment, can solve the problems of energy waste, heat dissipation of steam condensed water, large energy consumption, etc., and achieve the effects of reducing production cost, efficient utilization, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

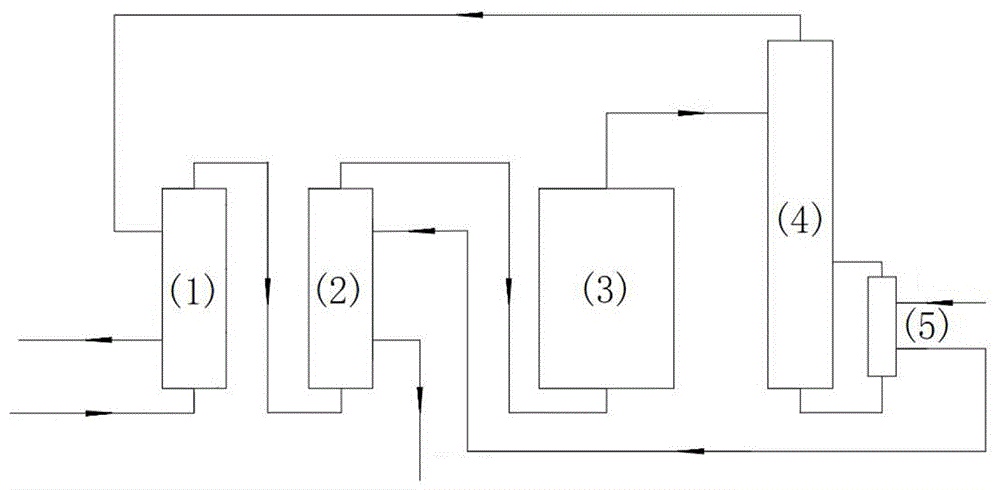

[0019] An energy-saving device for the vaporization of organic silicon monomer raw material chloromethane, the top of the thermally coupled heat exchanger 1 is connected to the bottom of the steam condensed water preheater 2, the top of the steam condensed water preheater 2 is connected to the bottom of the reactor 3, and the reactor 3 The top is connected with the rectification tower 4, and the bottom of the rectification tower 4 is connected with the rectification tower reboiler 5 and then connected with the lower part of the rectification tower 4 to form a circulation loop.

[0020] The rectification column reboiler 5 is connected to the upper part of the steam condensate water preheater 2 .

[0021] The top of the rectification tower 4 is connected to the upper part of the thermal coupling heat exchanger 1 .

[0022] The bottom of the thermal coupling heat exchanger 1 is provided with a liquid methyl chloride inlet pipe; the lower part is provided with a rectification towe...

specific Embodiment approach

[0025] Liquid chloromethane first enters the thermally coupled heat exchanger (1) for primary preheating, and the heat medium used for preheating is the high-temperature gas at 50~60°C extracted from the top of the rectification tower (4); then enters the steam condensate water preheating Heater (2) performs two-stage preheating. The heat medium used for preheating is 1.0MPa steam condensed water. The 1.0MPa steam condensed water comes from the rectification tower reboiler (5). The heated gaseous methyl chloride has a temperature of 50~60°C and a pressure of 0.3~0.8MPa, and enters the reactor (3) for the synthesis reaction of organosilicon monomers, and the reacted gaseous mixture enters the rectification tower (4) for purification and rectification The high-temperature gas extracted from the top of the tower (4) enters the thermally coupled heat exchanger (1) as a heat medium to cool, and then enters the condenser to condense, and can be extracted as a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com