Method for preparing super-macroporous high-specific-area polymer

A high specific surface area, polymer technology, applied in the field of polymer materials, can solve problems such as small adsorption capacity, and achieve the effects of simple post-processing, simple and reliable preparation method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

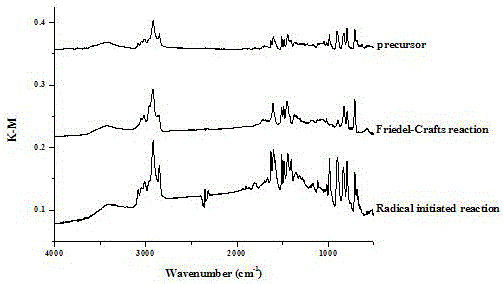

Image

Examples

Embodiment 1

[0029] Dissolve 4.0 ml of divinylbenzene monomer in 16 ml of dimethyl sulfoxide, add 36.8 mg of benzoyl peroxide, 19 μl of N,N-dimethylaniline, mix well, blow nitrogen for 5 min to remove oxygen, and After reacting at 18°C for 96 hours, place it at room temperature until the crystals of dimethyl sulfoxide melt, wash thoroughly with methanol, then wash with deionized water to remove methanol, put it in an oven at 50°C and bake to constant weight to obtain super-macroporous polymer thing. The obtained polymer has a specific surface area of 140.35 m 2 / g.

Embodiment 2

[0031] Take 20 ml dichloroethane and 40 mg anhydrous FeCl 3In the reaction kettle, ultrasonically disperse, add 100 mg of the polymer precursor obtained in Example 1, pass through nitrogen for 10 minutes, remove oxygen, seal, swell for 1 hour, then place it in an oil bath at 85 ° C for 18 hours, cool Afterwards, it was fully washed with methanol, washed with 0.1 mol / L hydrochloric acid, soaked, rinsed with deionized water, and dried in an oven at 50 °C to constant weight to obtain a polymer with super large pores and high specific surface area. The specific surface area of the obtained polymer is 1214.19m 2 / g.

Embodiment 3

[0033] Take 20 ml of dichloroethane and 10 mg of benzoyl peroxide in a reaction kettle, dissolve them, add 100 mg of the polymer precursor obtained in Example 1, blow in nitrogen for 10 minutes, remove oxygen, seal and swell for 1 hour , and then placed in an oil bath at 85 °C for 18 hours, cooled, washed thoroughly with methanol, and then washed with deionized water, and dried in an oven at 50 °C to constant weight to obtain a polymer with super large pores and high specific surface area. The specific surface area of the obtained polymer is 84.77 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com